By the end of the decade, modular gas-to-liquids (GTL) plants distributed around wellheads in places such as North Dakota, USA, and Siberia, Russia, may become commonplace as pressure mounts on producers to monetize marginal natural gas resources.

Small-scale GTL plants take the unwanted natural gas that is a byproduct of oil production, known as associated gas, and transforms it into more valuable liquid products. The technology can also be used to produce stranded gas reserves where a lack of distribution infrastructure exists.

The current disparity between crude and natural gas prices and the ever-rising estimates of global natural gas reserves are driving oil companies to study the feasibility of using small-scale GTL plants. North America, where the use of hydraulic fracturing has led to a surge in oil and gas production, will likely be the first region to see the widespread adoption of modular GTL technology.

With every new oil well that comes online, operators face tighter pipeline constraints, less gas-processing capacity, and increasing scrutiny from both regulators and the public sector on the disposal of associated gas through flaring. The associated gas that bubbles up with the crude is a phenomenon virtually all oil wells experience and, according to a 2011 report published by the World Bank, more than 5 Tcf of this gas is flared annually while another 15 Tcf is estimated to be reinjected.

Two companies, CompactGTL and Velocys, are at the forefront of small-scale GTL development, and both have systems designed specifically to address the untapped markets that associated and stranded gas represent.

CompactGTL, based in the United Kingdom, has plans to commission its first modular GTL plant in North America by the end of 2016 to produce synthetic crude oil, or syncrude, from natural gas. Syncrude, a milky white substance, is so free of impurities such as sulfur that it can command a premium price over crude oil because of the flexibility it gives refiners to optimize their operations. “There is an enormous amount of interest in North America for this solution,” said Iain Baxter, director of business development at CompactGTL. “The ability to take natural gas at the point of production and convert that into oil there and then—that is an incredibly valuable capability.”

In 2011, CompactGTL said it commissioned the world’s first integrated modular GTL facility, which was paid for and is owned by Petrobras in Aracaju, Brazil. The USD-45-million demonstration plant was qualified and approved a year later for commercial deployment by Petrobras, which continues to produce up to 20 B/D of GTL products from the facility.

A small-scale GTL plant requires about 10 MMscf/D of gas to produce 1,000 B/D of syncrude that, if commingled with the conventional product in the existing export line, negates the need for any additional infrastructure other than the plant itself.

“To produce syncrude and to be able to blend that back in with the mineral crude then gives you, quite simply, additional oil production,” Baxter said. “Now you have a field that only produces oil and that, in many cases, is what our customers plan to do.”

Using small-scale GTL plants to tie in multiple sources of associated or stranded gas makes oil fields more profitable. Deployed at the wellhead, GTL plants eliminate the need for the reinjection of natural gas into the reservoir to add pressure, which can stabilize production rates, but can also damage the reservoir. In shale formations in which hydraulic fracturing is used, reinjection is normally not done because of technical difficulties and cost.

How It Works

Coal is still used in some GTL plants but natural gas is now the preferred hydrocarbon, because it is in high supply and is easier to convert into liquids. Today, the most vital components of GTL technology, such as gas reformers and reactors, have been miniaturized, making the process more affordable. Advancements in microtechnology have led to enhanced reaction times and transfer of heat and mass, which enables the manufacturing of plants that are many times smaller than conventional GTL facilities.

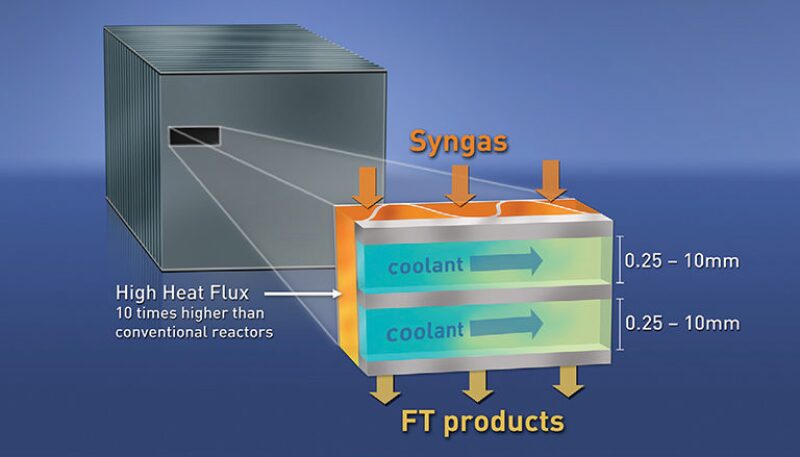

GTL plants are unlike liquefied natural gas (LNG) and compressed natural gas (CNG) facilities, which use a physical, not chemical, process to clean and condense gas into a transportable form. A typical small-scale GTL plant processes natural gas through a steam methane reformer, or an autothermal reformer, to begin the conversion of the gas into a mixture of hydrogen and carbon monoxide called synthesis gas, or syngas. The hot syngas is normally cooled using a waste heat boiler and then fed through a Fischer-Tropsch (FT) reactor. The catalytic process inside the reactor is designed to make longer chains of hydrocarbons using syngas and pressure, which can result in superclean diesel fuel, jet fuel, kerosene, naphtha, or syncrude.

The reactor also produces hydrogen gas, which can be used as a fuel to help power the GTL plant. In addition to syncrude and diesel, a GTL plant can produce other products including industrial waxes and many of the feedstock chemicals needed to manufacture high-grade lubricants and plastics.

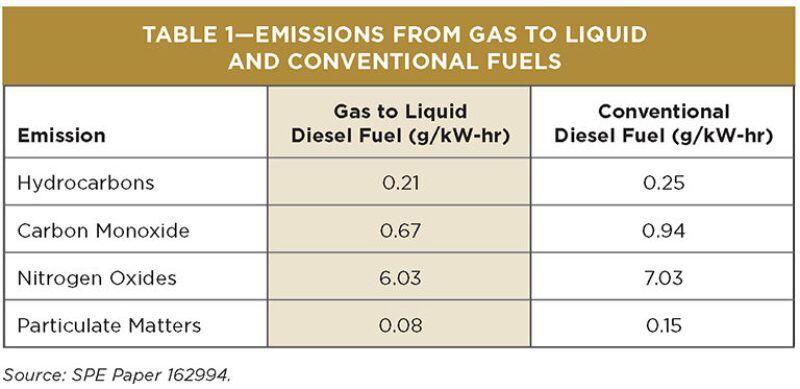

GTL fuels are considered “green fuels,” which also include fuels such as LNG, CNG, biodiesel, and hydrogen. These fuels produce fewer pollutants when burned, and are not as corrosive as conventional fuels (Table 1).

GTL technology also holds promise for the offshore industry. CompactGTL partnered with offshore facilities engineering firm SBM Offshore to develop a conceptual design for a GTL floating production, storage, and offloading unit that can process up to 37 MMscf/D in associated gas to produce 2,300 B/D of syncrude and an additional 400 B/D of natural gas liquids.

Microchannel Technology

Calumet Specialty Products Partners is also involved in GTL development. It plans to build a 1,000 B/D GTL plant at an existing processing facility in Pennsylvania, with first production possible by 2015. The company behind the project, Velocys, has developed modular GTL technology based on microchannel reactors and also has a demonstration plant in partnership with Petrobras that produces 6 B/D of GTL product in Fortaleza, Brazil.

A notable advancement that makes small-scale GTL plants possible is the microchannel technology, or minichannel technology, that companies are using to deploy FT reactors many times smaller than conventional FT reactors. The microchannels, just millimeters across, are arranged in arrays and help remove heat faster than larger channels. Using microchannels to dissipate the heat allows for more efficient catalysts, the secret ingredient of GTL technology, to be introduced to the reaction, giving small-scale GTL plants a higher conversion rate than their larger counterparts.

A conventional FT reactor is almost 200 ft (60 m) in length and must be installed vertically compared with a small-scale reactor that uses microchannels, which can be as small as 25 ft (8 m) in length and can sit horizontally. Industry experts use the analogy that microchannel technology is to the GTL industry what microchips were to the computer industry, because the innovation accelerates the chemical process between one and three orders of magnitude.

An Alternative to Flaring

While flaring is outlawed in some countries, it is a common practice in many regions of the world.

“Various regulatory bodies are reluctant to enforce bans on flaring, because of the loss of revenue from oil production that they get,” Roy Lipski, chief executive officer of Velocys, said. “But as soon as there is a viable commercial solution that makes money to the producers, such as smaller-scale GTL, that will allow the regulators to come down much stronger on them to do something about flaring.”

Because regulators in Russia, Nigeria, and in other countries with high levels of flaring are increasingly seeking to snuff out the flares and collect more revenue from the production meters, the makers of GTL technology believe their market will inevitably expand beyond the shale fields of North America and become truly global.

“As a world, we are moving into an age of gas surplus,” said Lipski. “That is the trend for the next 50 years of this story.”

Small Scale vs. Large Scale

The world of large-scale GTL is dominated by two energy firms, Royal Dutch Shell and South African energy company Sasol. Sasol has announced plans to build a 96,000 B/D GTL plant in Louisiana, with production set to begin by 2018.

Upon completion, Sasol’s Louisiana plant will be the second largest in the world next to Shell’s Pearl GTL plant in Qatar that produces 140,000 B/D of clean fuels and other chemicals. Shell is also considering building a GTL plant along the US Gulf Coast where most of the country’s petrochemical facilities are located. Chevron, in partnership with the Nigerian National Petroleum Corporation, will join the fray when production begins late this year at a 36,000 B/D GTL plant that is in the final stages of construction in Escravos, Nigeria.

The Gas-to-Chemical Option: Turning Gas into Benzene

Lipski pointed out that the capital expenditure needed to order small-scale GTL plants is far less than what large-scale GTL facilities require. “Instead of 10 billion (USD) plus investments, it’s only a matter of a 150 million (USD) starting price,” he said. “And the amount of gas required is significantly less, 10 to 100 times less than what you need for these big plants, which means there are many, many more fields and locations where it can be done.”

It is estimated that only 6% of the world’s gas fields store enough reserves to feed a 10,000+ B/D GTL plant. In contrast, the percentage of gas fields that can produce up to 2,000 B/D of GTL products at a profit is 40%. In a company presentation, Velocys estimates that 10 billion bbl of synthetic fuels could be produced each year by small-scale GTL plants.

Both Velocys and CompactGTL emphasize the importance of making the various components, or modules, of a small-scale GTL plant the same size as shipping containers so that they can be transported across oceans, or even by cargo plane, and then put on the back of a truck to be delivered to wherever the gas is. It is this design feature that gives the owners of a GTL plant the ability to deploy the technology in remote locations and even redeploy it to another field as economics demand.

Velocys has adopted the mass manufacturing techniques used by the auto industry, including the use of robotic assembly systems, to fabricate the various pieces of their GTL plants, which will produce anywhere between 1,000 B/D and 15,000 B/D of GTL fuels.

The Gas Technology Institute (GTI) is working on its own projects to improve GTL technology. One such project under way in conjunction with Aerojet Rocketdyne is to provide an alternative design of the front-end process of GTL, the conversion of natural gas to syngas, by combining two systems: a compact partial oxidizer and a turbo expander. The partial oxidizer essentially replaces the steam methane reformer through an incomplete combustion of methane to yield the syngas.

A unique component of the system is the turbo expander that removes the need for a thermal management system, such as a waste heat boiler or heat exchanger, by taking the energy of the gas produced in the partial-oxidation reactor and sending it through rotating equipment that expands the volume of the syngas, thereby effectively lowering its temperature. The process reduces the amount of steam needed while generating electric power and cooling down the syngas to a point at which it can then be converted into a liquid by means of a FT reactor.

The GTI and Aerojet Rocketdyne system was originally developed to enhance coal gasification technology more than a decade ago, but with natural gas prices forecasted to remain relatively stable, a decision was made to redevelop the technology for the emerging GTL sector. Among the other GTL-related projects that GTI is working on is direct-electron-beam synthesis to replace the partial-oxidation step to provide an even lower energy intensive system.

“I think there is a domestic interest (in small-scale GTL technology) that is going to be fairly long-lived because of our newfound abundance of gas supply,” said Vann Bush, managing director of energy conversion at GTI. “There is an international interest for some of those same reasons of trying to make a higher value product, but also to manage the logistics and environmental implications of associated gas.”