Microfluidics—the study of fluid interaction in micro- or nanometer-sized channels—is a science that has existed in the biomedical field for decades. In fact, it is used quite extensively in many everyday objects, such as pregnancy tests or inkjet printers. Only more recently has the science been broadly adopted in the energy sector. Microfluidics, fluid mechanics, and fluid transport have been studied extensively in academia, and it is from these academic labs that brilliant ideas give way to potential commercial success.

In 2015, David Sinton wrote an article for The Way Ahead speculating on the potential for micro- and nanofluidics to have a mega-sized impact on the energy industry. In that article, he wrote about the potential for the technology to evolve from the academic tool that it was to one that could be used in an operational context for stronger and faster decision making. This was how Interface Fluidics, a technology oil and gas laboratory services company, was born. Sinton, who is with the University of Toronto; one of his postgraduate students; and an energy analyst joined forces to take a concept from the Sinton Lab and commercialize a suite of microfluidic fluid-property-analysis tools and flow-through-porous-media visualizations to rival the status quo. Interface was the first company to be spun out of the laboratory, and it has pursued the mission of making fluid analysis ubiquitous and accessible for industry to enable long-term thinking and decision making. Since its inception, the company has grown to more than 30 employees, working with clients in Canada, the United States, Norway, France, Saudi Arabia, and Oman.

When large companies work with academic laboratories to solve a problem, they increase the potential for startups to be formed; this is especially true when testing novel technologies. In Interface’s case, Suncor heard about the microfluidic work being done in the Sinton Lab from the University of Toronto and connected with Sinton to explore the options for a project.

“This initial project with the lab and Suncor opened up the door to many possibilities,” said Tom de Haas, chief operating officer and cofounder of Interface Fluidics. “Their willingness to invest in a novel technology gave us the runway to truly explore the realm of possibilities for applying microfluidics to the oil and gas sector. After the research and development was complete, we were able to assess steam additives for bitumen production in a more-timely fashion and for a reduced cost when compared to traditional lab tests such as a sand pack.”

For de Haas, this initial project working with Suncor demonstrated that there was market demand within the oil and gas industry for microfluidic testing, and the data ultimately helped operators make more strategic decisions. By exploring the relationships between chemistries and oil, operators have a better understanding of what fluids are helping, or hindering, their oil recovery. Further, this new type of testing provided visuals of the fluid/fluid interactions that previously had not been seen before.

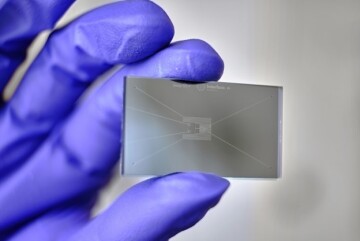

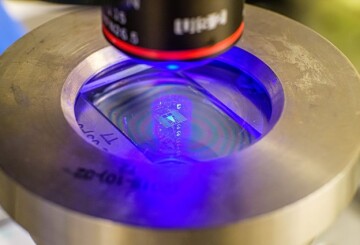

Interface built upon that initial thermal solvent testing experience and began developing a frac flowback test that ended up being their first commercial success (Figs. 1 and 2). “It was with the flowback test that we saw our data begin to repeatedly solve problems for operators,” said Stuart Kinnear, chief executive officer and cofounder of Interface. “The data we were able to show clients was the first of its kind, and it gave them the platform to actually see how chemical additives were affecting their reservoirs.” Since Interface started offering flowback testing, projects have been completed with global chemical manufacturing companies and North American shale operators including four of the top five global oil producers. Interface more than doubled its client base each year from 2015 through 2019, and the fracturing chemistry screening service has been able to shed light on problems that were previously difficult to quantify. Two highlights from 2020 include quantifying the high temperature stability of surfactants and, in another case, understanding sensitivity of production to surfactant concentration. The second case led to a 50% savings in chemical cost.

As Interface took on more clients, the role of partnerships grew and opportunities for research and development increased. Initial client meetings provided valuable insight into the problems that the energy industry was facing and revealed that microfluidics could potentially help solve them. The company joined Techstars Energy Accelerator and was a part of the first graduating class. Techstars is internationally known for providing a platform for technology startup companies to grow, and, in doing so, it provided Interface the opportunity to work closely with an industry leading partner on their commercial development.

“Through Techstars, we were able to work directly with Equinor on a specialized PVT [pressure/volume/temperature] project,” Kinnear said. “This project led to Equinor wanting to be an investor in our Series A investment round that closed in mid-2019.”

Interface now has a suite of fluid analysis capabilities that provide clients with visuals of what is happening at the pore scale using cameras, microscopes, and proprietary machine vision software.

“Using our reservoir analogs, we’re screening fluids at high pressure and high temperature, truly reservoir relevant conditions,” Kinnear said. “We’re able to show clients wax appearance or why a particular chemistry causes damage to their reservoir and how that impacts ultimate oil recovery.”

Over the past 2 years, Interface has been featured on the cover of the industry-leading SPE magazine JPT; has published papers at the Unconventional Resources Technology Conference, the SPE Annual Technical Conference and Exhibition, the Abu Dhabi International Petroleum Exhibition and Conference (1, 2), and the SPE International Conference and Exhibition on Formation Damage Control; and has expanded its presence internationally.

“Coming from humble beginnings at the University of Toronto to a commercial success story has been all but easy, but every partner and conversation along the way has impacted the growth and trajectory of our small company,” Kinnear said. “And we couldn’t have done it without them.”

Key Takeaways

- Industry partnerships with academia provide university researchers insight into industrial problems that need to be solved.

- Alignment between an academic project and a market need produces an environment where technology commercialization can take place.

- The technology that a startup commercializes may change. Many startups pivot to selling a product that is different from what they initially envisioned.

- Participation in conferences and industry events put on by professional organizations such as SPE help to build a company’s technical credibility and professional network.

- Startup accelerators such as Techstars provide companies with access to customers and capital. This is an option for startups that intend on rapid growth.

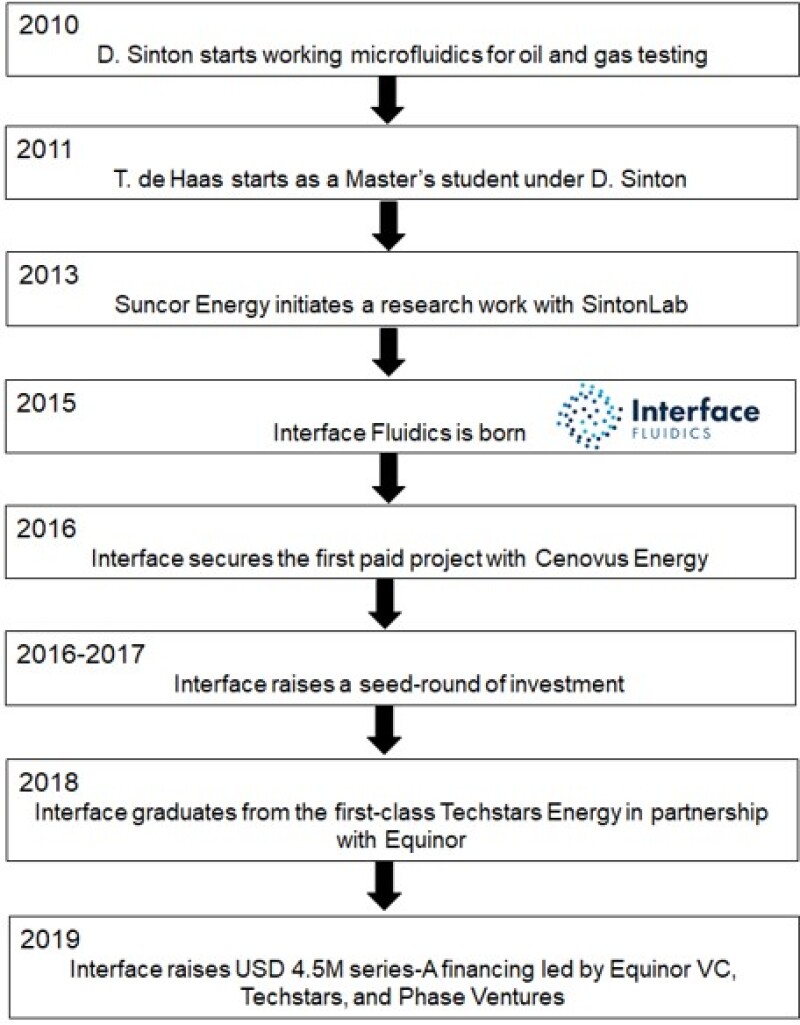

- In short, Fig. 3 shows the chronological flowchart of the Interface nanotechnology progression from the university level to industrial implementation.

Fig. 3—Flowchart of Interface Fluidic’s technology progression from university to implementation.

Jamie Anne Vaughan is the marketing and communications lead at Interface Fluidics. She is a member of the board of directors of the Calgary Section of SPE and has 6 years of experience in communications in the midstream and laboratory services industry.

Tom de Haas is the chief operating officer and a cofounder of Interface Fluidics. He holds a master’s degree in mechanical engineering from the University of Toronto, where he studied under David Sinton, also a cofounder of Interface Fluidics. He is passionate about the commercialization of microfluidic technology in the oil and gas industry. For questions about Interface Fluidics, de Haas can be reached at tom.d@interfacefluidics.com.