Being ready to operate is one of the most critical steps in the development of an oil field. For complex projects characterized by technical risks and challenges, a structured approach is mandatory to ensure operational excellence and readiness.

This study shows the methodology adopted by Agip KCO to achieve operational readiness for the Kashagan Field development project by means of a management system called Operations Readiness and Assurance (ORA). The ORA process assures that the field production facilities are designed, built, commissioned, and started up with account taken for lifecycle operations requirements. This will lead to a safe, cost-effective, and quick ramp up to target production levels.

This methodology has been successfully applied at the Kashagan field. Kashagan is an extremely complex development in terms of technical issues that involve high-pressure, sour-hydrocarbon reservoir development in a hostile environment. The management system applied through this methodology has enabled the operations team to be integrated fully in the field development, so that the team serves as a key decision maker in facilities operability and risk mitigation.

Introduction

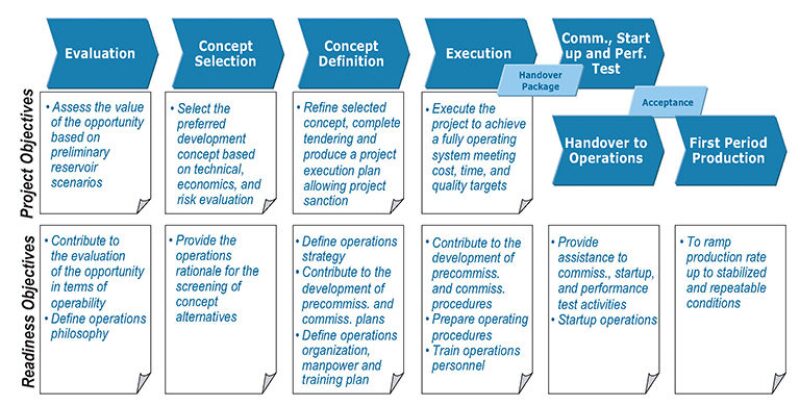

Operations input by means of the ORA plan is fundamental from the very first phase of a project through the handover and the first period of production. The role and contributions of operations change during the different phases of the project, and thus the key deliverables that require preparation. Fig. 1 provides a high-level description of the role of operations—indicated as readiness objectives—in different project phases.

Methodology: ORA Process Structure

The ORA process built within Agip KCO is guided by the following principles:

- Operations involvement at early stage of the project is an additional control element in managing the risks and uncertainties related to reservoir behavior and subsequent facilities design.

- The ORA process has a strong link with the project. ORA activities and timelines are strongly dependent upon project phases and are guided by the project gates and milestones. All activities planned by operations are fully integrated with the project plan, to produce properly defined design specifications.

- The complexity of the handover process from project to operations is one of the most critical steps in operations readiness. Thus, an integrated commissioning and acceptance team, whose members are both project and operations personnel, is designed into the ORA plan. This integrated approach is needed to guarantee a smooth handover to production operations.

- RA process and deliverables require a strong coordination with departments outside of operations. Operations is the final client in the field-development process, and this requires a strong interface with external departments and stakeholders.

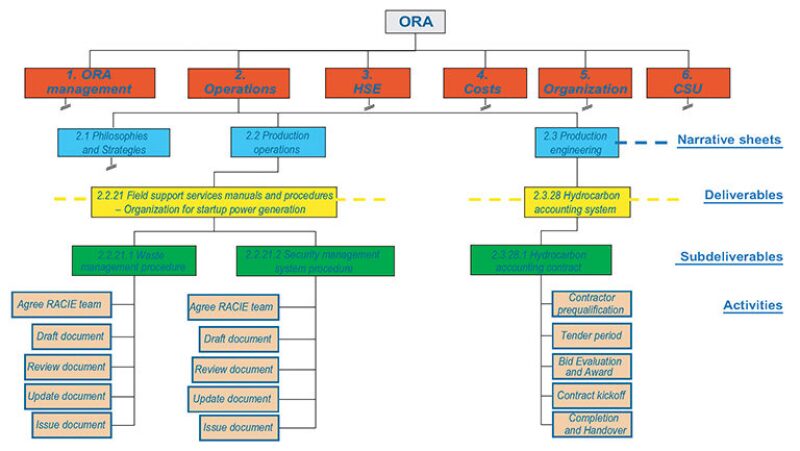

Agip KCO has organized the ORA items in a structured hierarchy (Fig. 2), consisting of

- Level 0—Overall ORA, representing sum of all ORA activities

- Level 1—Processes fundamental to operations readiness, including ORA management, operations, HSE, costs, organization, and commissioning and startup

- Level 2—A set of narrative sheets that break down each level-1 focus area into detailed subprocesses, specifying key objectives, overall readiness criteria, and key deliverables for the particular item (e.g., production operations, production engineering, maintenance, etc.)

- Level 3—Highest level of deliverables (i.e., group of operating procedures)

- Level 4—Sublevel deliverables, including documents (strategies, procedures, and plans), contracts (executed in a timely manner for the transition to the operations phase), and systems (typically operations information systems)

- Level 5—Activities required to prepare each subdeliverable

The working tool generated from the ORA structure by means of the processes is an integrated-reference comprehensive schedule. The ORA schedule provides a complete overview of the activities timeline and the resource demand profile, and hence enables operations to optimize resource allocation/utilization and identify delays and responsibilities.

Methodology: ORA Governance

The ORA governance is aimed at providing the key decision makers within the operations department with a structured approach for ensuring that the ORA plan is executed quickly and efficiently. This will guarantee an internal alignment within the department and an adequate engagement from external stakeholders (e.g., external Agip KCO departments, authorities, coventure partners).

The following responsibilities are assigned:

- Level 0—ORA manager (1)

- Level 1—ORA champions [selected from senior operations management] (6)

- Level 2—ORA narrative accountables manager (1)

- Levels 3 and 4 : ORA deliverables responsibilities manager (number dependent upon the number of deliverables)

For each level of the ORA structure, the decision makers will have the following tasks:

- Report the status of the ORA activities to the responsible person at the level above.

- Liaise with people at the same level in the ORA governance structure to resolve any issues and to ensure cooperation.

- Escalate unresolved issues to higher levels of the governance structure, if necessary.

- •nterface with departments outside of operations to guarantee a two-way flow of information and ensure provision of relevant inputs.

Methodology: ORA Progress Monitoring System

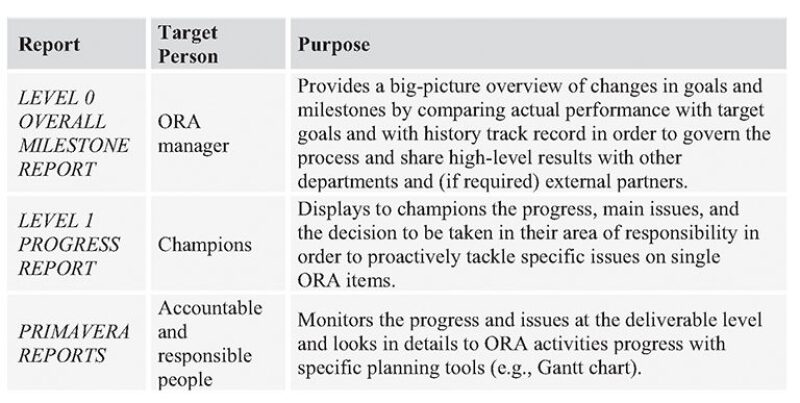

The progress monitoring system encompasses continuous control of ORA activities progress by means of a structured set of reports (at different levels of the hierarchy) that feed a control-action loop. For each type of report, Fig. 3 provides details of the target person and the purpose.

Conclusions

The application of this innovative management system has enabled operations to achieve the following.

- Ensure full alignment between the production and maintenance requirements in terms of ORA and the external interfaces within Agip KCO.

- Increase overall readiness progress for the department by 10% vs. a planned 2%, without the additional resources devoted.

- Improve facilities design quality and reduce reservoir uncertainty risk.

- Ensure that all activities/deliverables risks for which operations is the final client receive due analysis, with mitigation steps planned and executed as needed.