Excellence in project execution requires continuous innovation in the oil and gas industry. Academia, industrial laboratories, engineering centers and individual entrepreneurs strive for new ideas that expand the horizons of our activities and help satisfy society’s needs. This article introduces our “Tech 101” series, a new TWA section where new technologies, breakthrough research projects, and industry lessons learned will be featured to enhance young professionals’ development. This article is devoted to a type of conveyance technology that modifies the face of wireline operations in horizontal and highly deviated wells. WellTec, one of the leaders in this arena, presents its vision of the current status of tractor technology and its future development. Josh Etkind, Interim Editor, and Oleg Zhdaneev, Editor, Tech 101 Series

The development of wireline-tractor technology has greatly improved the way operators can intervene in high-angle and horizontal oil and gas wells. The use of downhole tractors continues to expand the opportunities for planning and executing interventions, which are an important means of sustaining and increasing production. Furthermore, the technology significantly reduces the personnel safety risks and environmental footprint associated with other intervention methods.

By the 1990s, horizontal and deviated wells had become an important step change in the development of low-permeability oil and gas reserves and reservoirs produced by means of extended-reach (ER) wells. The increased cost and risks placed on the existing technology for every phase of the well—drilling, completion, production, and abandonment—challenged the industry to find new methods, including those for interventions.

In 1994, Jørgen Hallundbæk decided to bring to market an idea developed as a part of his graduate thesis while a student at the Technical University of Denmark. The project he had been working on since 1987 involved the engineering of a precision robotic tool that would answer the industry’s need for a more economic means of intervention in high-angle and horizontal wells. At the time, access to horizontal boreholes for data acquisition and services was only possible through pipe-conveyance methods that required a rig or coiled-tubing (CT) unit. Consequently, interventions to increase production were performed only when production had suffered a major decline and not as a means of achieving the incremental improvements that are part of good production management. The tool developed as a result of Hallundbæk’s initiative, the Well Tractor, was introduced to address these needs.

The tractor is a wireline-deployed, self-propelled robotic device that pushes wireline tool strings out to the end of the wellbore. Before the invention of the wireline tractor, the only feasible ways to reach the end of a horizontal wellbore were by means of snubbing with threaded tubing or through the use of CT methods. With the wireline tractor—intervention tools are able to reach the end of the horizontal or highly deviated wells without mobilizing and deploying pipe-conveyance methods. Further, any job that was previously done on slickline, in vertical wells, can now be done in a horizontal or deviated well, with the use of wireline tractors—resulting in safer, faster, and more cost-efficient jobs.

The wireline tractor is powered by an electric/hydraulic system (Fig. 1). The control panels, communications, and internal power source are electric, while the remaining parts and functions are hydraulic. When activated, the wheels are hydraulically deployed out of the tool body and automatically start to rotate. Each wheel contains its own independent hydraulic motor, which facilitates the forward motion in the well. The tool centralizes itself in the wellbore, once contact with casing has been established, and then deploys intervention tools into the well, taking the string beyond its original hangup point.

To provide good communication with the winch driver, the surface control panels that control the tractor’s progress in the well normally are positioned inside the wireline unit. Diagnostic data are relayed back to the surface to the engineer’s computer.

For ER wells, a CT tractor also has been developed for pumping operations. This version extends the reach of CT in highly deviated or tortuous wells, where conventional intervention techniques cannot pass. The fluid-driven CT tractor extends the CT’s lateral reach in both horizontal and deviated wells by several thousand feet beyond that achieved by any other method. The tractor pulls the CT out into the wellbore, overcoming the tendency of the coil to buckle and lock up. This allows for the use of a smaller-diameter coil, with less wall thickness, or composite CT, which reduces reel weight and eliminates problems related to crane lifting limitations.

Lightweight Interventions

Before downhole tractors were invented, intervention methods necessitated many tons of equipment and dozens of people—all requiring transportation to the wellsite. In addition to the costs involved, there were safety and environmental risks related to personnel levels and equipment use. A downhole tractor, on the other hand, is approximately 20 ft long and only a few inches wide, and it does not require a rig. With its small size, it can be mobilized more quickly, at less expense, and with lower fuel consumption, emissions, and discharges than mobilizing a rig or full CT unit would involve. The tractor can be brought in by helicopter, if needed. The wireline tractor, along with its logging and mechanical services, can be deployed from a crane or mast unit, enhancing operating flexibility.

Crew size for the tractor can be reduced to two people, and remote-control options enable operating personnel to be situated off site, if desired. The smaller equipment footprint, lower crew requirements, and remote-control capability can be of particular benefit in offshore operations—where space and personnel restrictions often are factors—and in environmentally sensitive areas, including the Arctic.

Additionally, the ability to operate with wireline-precision depth control and large pull forces helps ensure that interventions do not affect the rest of the reservoir, nor risk damaging completion hardware, as can happen with pipe-conveyed and surface-pumping intervention methods.

Changing the Way Fields Are Managed

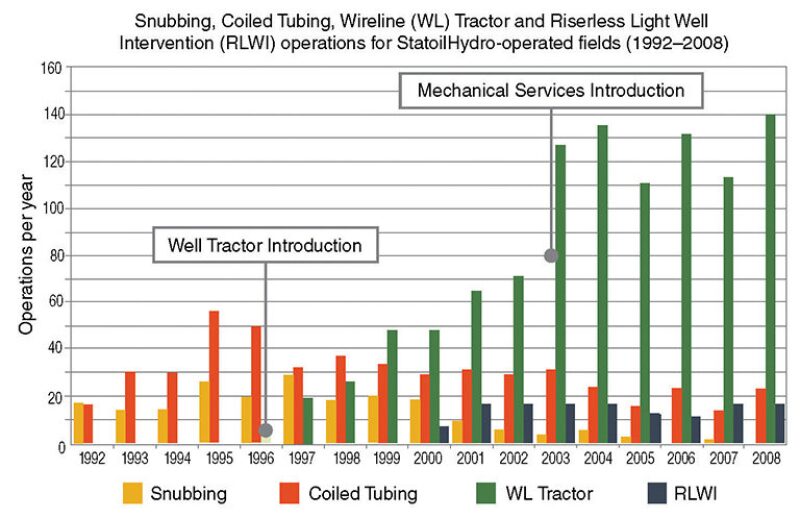

Operators have changed the way they plan and manage their fields, as a result of incorporating wireline tractors into their intervention and completion methods. One of the pioneer adopters, StatoilHydro, has realized great benefits since incorporating this technology in 1996 (Fig. 2). Today, approximately 80% of the company’s interventions are conducted by means of wireline tractors, while the focus of CT interventions has shifted primarily to large pumping operations. Reducing the cost while enhancing the capabilities of interventions has enabled StatoilHydro to expand the frequency and increase the scope of its interventions, resulting in added value now approximating USD 25 to 30 billion per year, the company estimates.

Mechanical Services

Mechanical downhole services on electric wireline, such as plug pulling/setting, valve shifting, cleaning, and milling services, are a further evolution in the use of wireline tractors. In addition to standard horizontal completions, there are many customized applications of the tractor technology, such as tandem tractor configurations to negotiate multilateral junctions, side pockets, Y tools, and washouts in open hole. Any job run on electric wireline in a vertical well can be done in a horizontal or deviated well with a downhole tractor. The application range is still expanding. The two case studies that follow are examples of what has been achieved thus far.

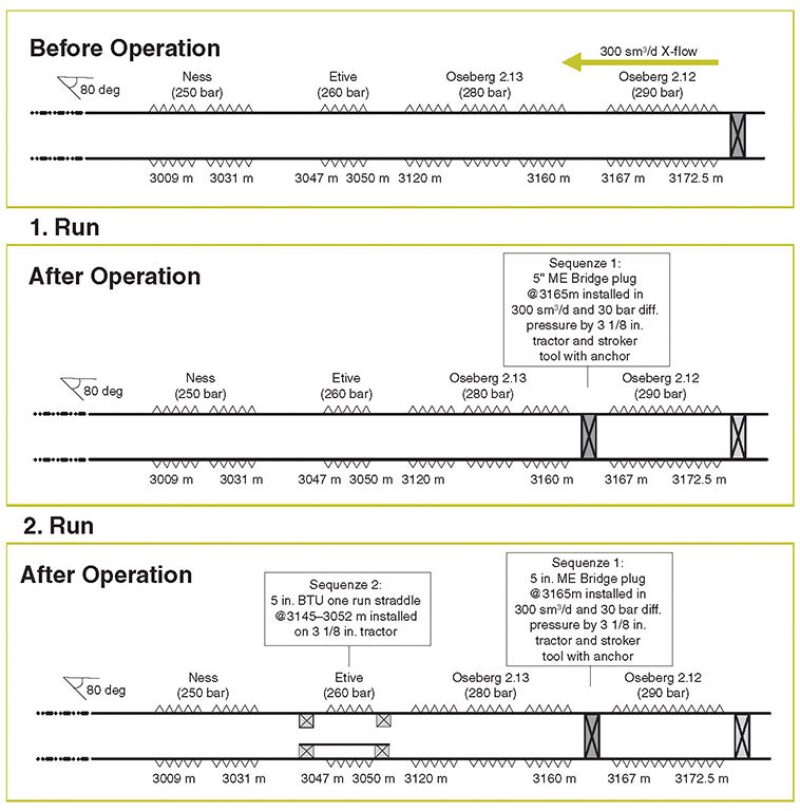

Case Study: Rigless Water Isolation

In July 2007, a technological breakthrough was achieved in shutting off water in a producing horizontal well. The challenge was to set a plug in a well that was perforated over several zones. The well had been diagnosed to have severe crossflow between zones with a large pressure difference, and this crossflow had reduced well productivity to a minimum. Because of the high crossflow, setting the plug was expected to be extremely difficult. Flow simulation indicated that the toolstring assembly, with an in-gauge plug, had a very high risk of moving uphole as setting was attempted, which risked tangling the wireline and eliminating the advantage of plugging the lower zone.

The solution was to anchor the plug-setting toolstring at the correct depth, with the use of a stroker conveyed by wireline tractor, while setting the plug by conventional means. The wireline stroker normally is used for setting and pulling plugs because of its ability to provide an axially focused force of up to 33,000 lbf. However, during this operation, it was used as an anchor to ensure the bridge plug was held in position long enough to be set. The plug was set at 10,384 ft in 300 sm3/d crossflow with a pressure differential of approximately 30 bar in a 5-in. liner. After setting the plug, the wireline tractor also successfully installed a 23-ft-straddle scab liner in one run across 9,990–10,013 ft to isolate a 10-ft water-producing interval.

The first well-test data after the water shutoff indicated that the water rate was reduced from 2150 to 150 sm3/d. The oil rate was maintained at approximately 200 sm3/d, and the water cut was reduced from 90% to 45%. As an additional benefit, the operation reduced the environmental impact attributable to produced water handling.

Case Study: BaSO4 Scale Milling on Wireline

An operator was seeing a reduction in production rate and believed this was caused by scale bridges above and inside the perforating zones between 12,200 and 12,870 ft. An attempt was made to remove the scale with slickline, but this method was not able to break through the scale.

The decision was reached to apply a milling tool on a wireline tractor, with near-bit centralizer, to remove the scale, following extensive onshore testing of the tool application (Fig. 3).

Very hard scale was encountered during the milling operation, which proved challenging. However, the milling tools, using various bits, cut away the BaSO4 scale down to the area between the fourth and fifth perforation intervals. The operator continued to produce the well as the milling progressed, so that the cuttings were brought to surface and separated. However, this did not allow for measurement of the cutting volume.

In a 10-day period, the tool milled through a scale restriction 200 ft in length, increasing the minimum diameter through the section from 1 to 4 in. This resulted in a net production increase of more than 3,000 BOPD. Cost savings were estimated at USD 800,000, compared with a CT application that would have faced great difficulties because of space restrictions.

Looking Ahead

The use of the downhole tractor has grown tremendously, since introduction of the technology in the 1990s, and now includes many applications beyond those of simple conveyance operations in horizontal wells. Since 2007, milling and cleaning applications performed on wireline have increased dramatically and have included executions in low-angle and vertical wells, where the tractor provides the weight on bit and controls the reactive torque. A number of successful scale- and bridge-plug milling applications have now been described in SPE papers. In December 2008, the first milling of nipple profiles on wireline took place offshore Indonesia, where six nipples in three wells were enlarged to clear the way for further intervention services. Previously, these operations required killing the well, circulating large volumes of fluid from surface, and mobilizing pumping and fluid-handling systems, along with CT spreads.

A particular industry challenge is intervention in longer and deeper wells. The next generation of downhole tractors will be capable of achieving twice the speed and force of current tools, enabling the coming tool lines to meet the requirements of extreme ER wells planned to approach 50,000 ft measured depth. With the growth of subsea wells in deep water, tractors are being designed for subsea interventions. Much potential exists in this sector. Subsea wells are infrequently intervened and have recovery factors of 30–35%, compared with a nearly 50% recovery factor for platform wells, where interventions are common.

With the lower costs, flexibility, smaller footprint, and reduced environmental and personnel risks of using downhole tractors for many operations, the number and variety of applications of this technology appear certain to grow in coming years. The industry may only have scratched the surface of what is possible to achieve on electric wireline. Novel intervention applications will likely be developed to unlock further reservoir potential through improved hydrocarbon recovery.

| Brian Schwanitz, SPE, has worked in the oilfield-service industry for 32 years, 25 of them with Schlumberger in various positions and product lines. He joined Welltec in 2002 as the general manager in Houston and is currently vice president of Global Sales and Marketing, based in Denmark. Schwanitz is in his 7th year on the international board of the Intervention and Coiled Tubing Association; he served 3 years as an SPE section officer and has 16 published papers and articles, including 12 SPE papers. |

| Kristine Henriques, SPE, has a master’s degree in communications from the University of Roskilde and a master’s degree in Spanish from the University of Copenhagen. She joined Welltec in 2006 as communications coordinator for the Branding Department. Her writing credits include more than 40 articles and publications. Henriques has coauthored two SPE papers. |