Oil and natural gas remain the leading forces of the world’s energy sources, accounting for 57.4% of worldwide energy consumed in 2016 (Frent, 2018). This is not projected to change as demand for hydrocarbons as an energy source continues to grow. However, the pace of growth is slowing, and the life cycle of new project developments faces significant challenges. The industry reports that 64% of projects surpass budgetary allowances and 73% are over schedule (Preiss et al., 2014). These project projections are worsened by increasingly complex technical designs and project scopes, in the face of a reduced workforce capacity and outdated communications technologies.

In light of the recent COVID-19 global pandemic, remote communications and the ability to work from a distance are more necessary than ever. In times of economic difficulty and crashing oil prices, cost savings are paramount to the recovery of the industry. Investing in remote communications technology will yield the necessary cost reductions both during and post-crisis to support the regeneration of oil market growth.

The growing challenge that companies face in remote environments is how to maintain reliable and effective communications with increasing data and technical needs. The oil and gas sector has begun to embrace the potential of the digital transformation. Both onshore and offshore worksites are in remote locations that require special safety measures to ensure workers maintain a clear line of sight while working with complex machinery. Implementing safety measures while collaborating remotely to complete technical tasks is challenging but can be tackled with emerging digital technologies and connectivity options.

New Options for Connectivity

Since the launch of the USSR’s Sputnik satellite in 1957, global mobile satellite systems have made huge strides in extending accessibility, range, and coverage of radio networks. The advancements in satellite have allowed companies to move large amounts of voice, text, and data communications across the globe regardless of their remote locations. However, with today’s mobile devices, internet access, and technically complex machinery, satellite connectivity endures mounting stress resulting in higher expenses.

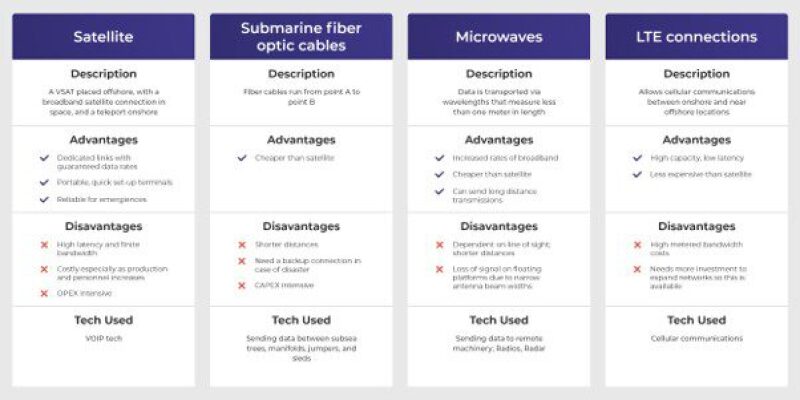

Currently, the oil and gas industry uses voice-over-internet-protocol technology, wearable technologies, and portable digital radios to communicate via very-small-aperture-terminal satellite, submarine fiber-optic cables, microwaves, and long-term evolution (LTE) connections. These options vary in terms of area of coverage, bandwidth, and latency problems, so solutions need to take these barriers into consideration.

[Click to expand.]

Challenges and Opportunities for Remote Connectivity

Currently, communications between worksites depend largely on satellite links, but each link can cost upwards of $200,000 annually (Verma & Kasem, 2019). When issues take place, every minute of downtime is extremely costly for companies. In refineries, every day that a pump is down for maintenance or failure, $1,000,000 of potential revenue is lost. Similarly, in exploration and production, companies have typically been required to send specialized experts onsite by helicopter to resolve the issue as quickly as possible. These displacements, however, result in further financial losses due to prolonged machine downtime and costly transportation expenses.

Now, however, key telecom actors such as Nokia are able to combine wireless broadband and IP-based technologies to provide oil and gas companies with the connectivity they need for big data applications, including automation, remote monitoring, and real-time asset management. With better connectivity, companies can invest in remote communication technologies to improve profits; enhance safety; and reduce mechanical, financial, and personnel risks.

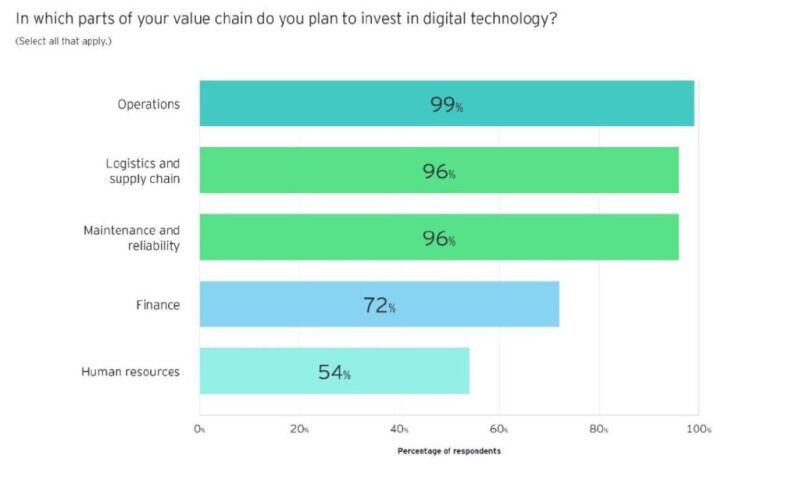

With new options for connectivity, and the growing popularity of LTE connections, there is a huge opportunity to close the digitalization gap. In fact, 89% of oil and gas executives foresee an increase in their investment in digital tools across the value chain over the next 2 years (Williams & Everaard, 2019).

[Click to expand.]

Companies can find inspiration for implementing digital technologies in their top value chain areas (operations, logistics, and maintenance) by looking to examples such as Norway’s Equinor, which has digitized its offshore platform, Valemon, in the North Sea. Companies like Equinor are integrating digital twin technology into remote operations centers to improve production and maintenance, which allows them to duplicate physical equipment or real-world processes in a virtual environment. This technology facilitates the optimization of value drivers such as “capital expenditure reduction, time-to-first-oil acceleration, recovery rate increase, production acceleration, operating expense reduction, and health, safety, and environmental improvement” (Holmås et al., 2019).

Digital Technologies To Improve Remote Communications

Digital partnerships are lucrative for operational and production benefits that may lead to key competitive advantages. More specifically, enhanced equipment monitoring through digital solutions allows operators to inspect the conditions of infrastructure and optimize communications remotely between worksites. By optimizing multiple processes across the value chain, maintenance, operational, and transportation costs are reduced. For some, implementing digital solutions has reduced maintenance costs by as much as 40% (Samoun et al., 2019).

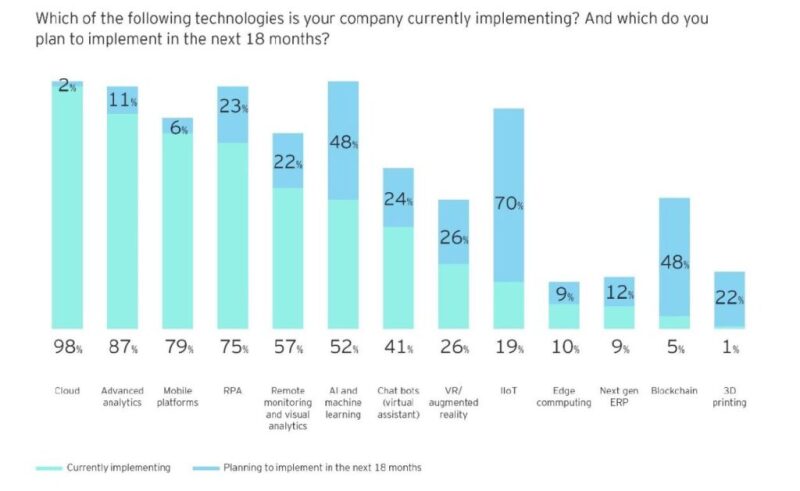

When asked which emerging technologies oil and gas companies are currently implementing, or plan to implement, executives responded as in Fig. 3.

[Click to expand.]

Integrating a combination of these technologies will increase accuracy of work and safety, thereby maintaining project and production pipeline expectations. For example, innovative software based on web real-time communications (WebRTC) technology such as ViiBE can be used in conjunction with augmented reality and industrial wearable technologies. WebRTC enables web browsers to combine data, video, and audio interactions through collaborative and conversational features to facilitate faster remote assistance. Combining innovative technologies will play a major role in increasing both communication efficiency and safety measures for remote workers.

Aligning With Corporate Social Responsibility

Embracing digitalization similarly helps companies more easily consider social and ecological concerns in their business practices. Leveraging digital technologies supports employee engagement and safety by considering risks and making changes that improve their daily well-being. Such corporate social responsibility considerations result in further cost reductions as safety improvements lead to fewer worker compensation payouts due to reduced accident rates.

Investing in technology to enhance remote communications is also beneficial for reducing the industry’s ecological impact. Through better equipment monitoring at a distance, companies can avoid unnecessary repair costs and reduce their carbon footprint by reducing the need to send helicopters and experts onsite to solve issues.

Conclusion

The oil and gas industry has made great strides in providing new kinds of connectivity to its remote and offshore worksites. It is not, however, taking full advantage of the opportunities to combine types of connectivity or partner with digital technologies. Remote communications in the industry are currently handled by voice communications, which is insufficient to maintain profits and complete projects in a changing, volatile landscape with diverse energy sources. Investing in a combination of digital twins, AR technology, industrial wearables, and remote visual assistance software will support more efficient and safe operations and communications.

References

Ben Samoun, Marie-Hélène, Håvard Holmås, Sylvain Santamarta, Peter Forbes, JT Clark,

and Whitney Hughes. (2019, March 12). Going Digital Is Hard for Oil and Gas Companies—but the Payoff Is Worth It. BCG.

Frent, Petra. (2018, May). Leading Players of the Global Oil and Gas Industry: Overview of Groups- SWOTs- Benchmarking- Company Profiles and Financials. Xerfi, 2018.

Holmås, Håvard, Odd Arne Sjåtil, Sylvain Santamarta, Sverre Lindseth, Peter Forbes, and Pietro Romanin. (2019, October 3). Creating Value with Digital Twins in Oil and Gas. BCG.

Preiss, Axel, Doug Burcham, Bradley Farrell, Craig Hogget, Claus Jensen, Chris Lewis, Marlon Richardson, Jim Perrine, and Chris Pateman-Jones. (2014). Spotlight on Oil and gas Megaprojects. EY.

Verma, Saurabh and Anas Kasem. (2019, December 16). 5G a Critical Enabler for Digitalization in Oil and Gas: Emerging Use Cases and Opportunities. Frost & Sullivan.

Williams, Jeff and Rachel Everaard. (2019, January 9). Technology can light the way, but do you know where you’re going? EY.

Marc Prempain is the cofounder and CEO at ViiBE Communications. ViiBE is a video-assistance technology without download dedicated to technical maintenance centers. Prempain helped a French oil and gas industry leader successfully deploy his telecommunications webapp in open sea. ViiBE is incubated by HEC and Zendesk at Station F in Paris and recently raised € 1.2 million. Prempain holds an MBA in international business. His LinkedIn profile: https://www.linkedin.com/in/marcprempain/

Kelly Dell is the success and content manager at ViiBE Communications. She works with ViiBE clients to determine their needs and enhance their experiences with the platform. In her previous position at Multilateral Organisation Performance Assessment Network, she led the project for coordinating the editing and publication of performance assessments that determine funding for organizations such as UNESCO, the World Health Organization, and the Asian Development Bank. Dell holds a BA degree from the University of California, Berkeley and an MA from Sciences Po, Paris in international public management with specializations in European affairs and diplomacy.