Carbon capture and storage (CCS) represents a suite of advanced technologies designed to capture carbon dioxide (CO2), a major greenhouse gas, and safely store it underground to mitigate its impact on climate change. This process involves two key methods: capturing CO2 directly from large industrial emission sources, known as point-source capture, and extracting it from the atmosphere.

With a global push to achieve net-zero emissions by 2050, CCS is evolving rapidly to address the dual challenge of reducing greenhouse gas emissions while ensuring energy security. As highlighted in the Global CCS Institute's CCS Technologies 2024 report, these innovations are reshaping industries like petroleum and energy, playing a pivotal role in the global energy transition. In this article, we delve into cutting-edge CCS advancements and their critical role in advancing clean, sustainable energy solutions.

The Role of CCS in the Energy Transition

CCS is central to achieving net-zero goals by addressing emissions from hard-to-abate sectors such as refining, power generation, and industrial processing. By capturing and securely storing emissions from these sectors, CCS serves as a bridge between the current dependence on fossil fuels and a renewable energy future. Additionally, it supports the production of low-carbon hydrogen—a crucial energy carrier for the future—and drives economic benefits through enhanced oil recovery (EOR) in mature reservoirs.

For petroleum engineers, CCS offers a transformative platform to apply their expertise in subsurface management and pipeline systems, ensuring safe and efficient CO2 transportation and storage. By fostering innovations in storage and monitoring systems, these professionals are uniquely positioned to facilitate CCS adoption and accelerate the energy sector’s transition to sustainability.

Cutting-Edge Capture Technologies

Carbon capture is the foundation of CCS, with the compendium showcasing several groundbreaking solutions:

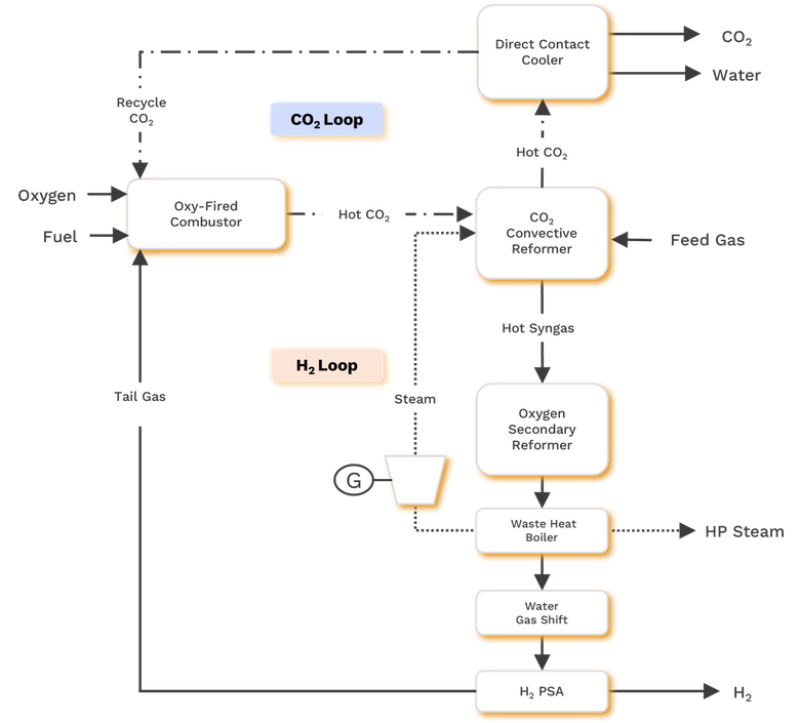

8 Rivers’ 8RH2 Process

In May 2023, 8 Rivers introduced 8RH2, an innovative ultralow-carbon hydrogen production process that captures over 99.5% of CO2 emissions cost-effectively. Central to the technology are the oxy-combustor and CO2 convective reformer, which utilize oxy-combustion and heat integration to improve thermal efficiency while eliminating the need for energy-intensive carbon capture systems (Fig. 1).

The first deployment, Cormorant Clean Energy in Texas, aims to produce 880,000 tonnes of low-carbon ammonia annually and capture 1.4 million tonnes of CO2, showcasing its potential to support clean energy transitions at scale.

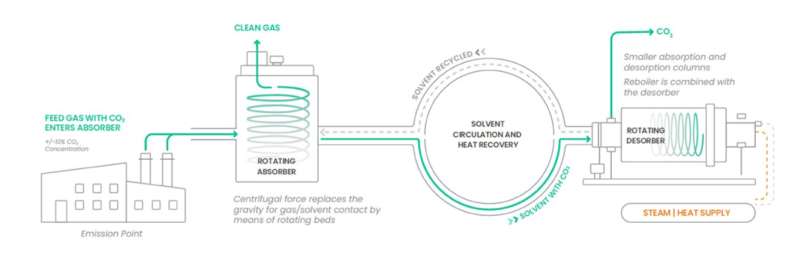

Baker Hughes Compact Carbon Capture (CCC)

CCC is a post-combustion carbon capture technology utilizing rotating packed bed technology to enhance mass transfer through centrifugal acceleration. This innovation reduces equipment size, capital costs, and operational expenses while achieving high CO2 capture rates (≥95%) and enabling compact, modular plant designs (Fig. 2).

CCC has been successfully piloted in Norway and is progressing toward larger-scale demonstrations, promising efficient deployment in small to medium emission applications, including offshore and brownfield sites.

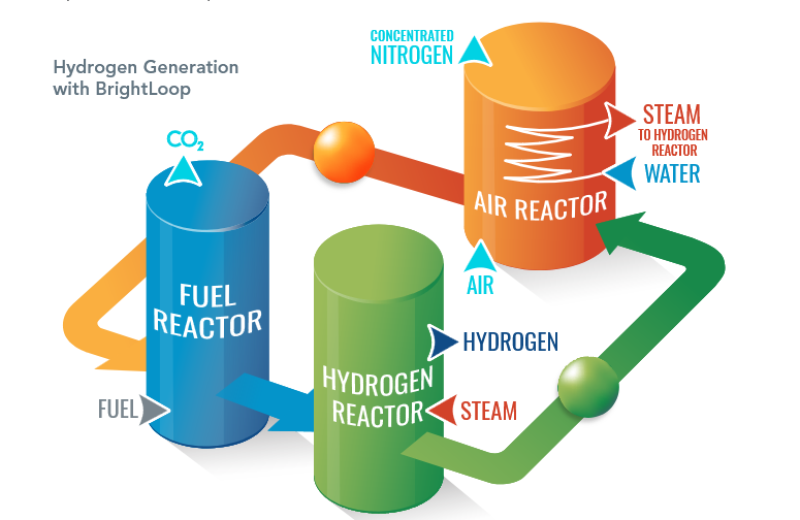

Babcock & Wilcox’s BrightLoop

BrightLoop technology uses a chemical looping process (Fig. 3), with iron-based oxygen carriers to produce hydrogen, syngas, or steam while isolating CO2 for sequestration or use, eliminating the need for post-combustion capture equipment. The process leverages proven moving and fluidized-bed technologies to efficiently transform various fuel types, including biomass, coal, and natural gas, into clean energy and byproducts with minimized environmental impact.

B&W has successfully deployed the technology at two pilot facilities. In one DOE-sponsored project, B&W built a 250-kWt coal-based coal direct chemical looping pilot facility to demonstrate the fuel reactor and air reactor operation for application to steam (and subsequently, power) generation. In another project, the company constructed and tested the 250-kWt pilot unit tested at the National Carbon Capture Center in Alabama during which continuous low-carbon hydrogen generation was demonstrated.

Axens’ DMX Process

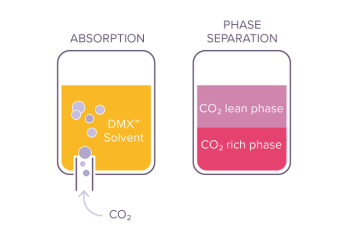

The DMX process, developed by IFPEN and marketed by Axens, is a second-generation carbon capture technology that uses a demixing solvent to reduce energy consumption by nearly 30% compared to traditional mono ethanol amine-based processes (Fig. 4).

This innovative solvent creates two phases upon contact with CO2, allowing for selective regeneration of the CO2-rich phase, significantly increasing efficiency and reducing costs. Designed for low to medium CO2 partial pressures, it is applicable to various emitters, including coal power plants, steel production, waste incineration, and cement facilities, offering advantages such as high stability, lower corrosivity, and reduced capital expenditures.

These technologies are tailored to tackle CO2 emissions in industries like petrochemicals, refineries, and power plants, where emissions are most concentrated.

CO2 Transportation: From Source to Sink

Efficient transportation is critical to the success of CCS. Once captured, CO2 is compressed to a liquid-like state for easier handling and then dehydrated to remove moisture before transportation. Pipelines remain the most common mode for moving large volumes of CO2, while shipping offers a practical alternative in certain regions.

"CCS Technologies 2024” highlights advancements in modular pipeline systems, compression technologies, and multimodal transport strategies. Petroleum engineers play a key role in optimizing these systems, ensuring safe, cost-effective CO2 movement from capture sites to storage reservoirs.

Geological Storage: Unlocking the Subsurface Frontier

Storage is the cornerstone of CCS, with geological formations, including petroleum reservoirs, providing ideal conditions for long-term CO2 sequestration. Innovative technologies like Carbfix’s process, which accelerates the mineralization of CO2 into rock, and microseismic monitoring systems, which ensure reservoir integrity in real time, are advancing the field. Saipem’s integrated systems offer end-to-end solutions, from injection to monitoring and verification.

Petroleum engineers’ expertise in reservoir characterization and simulation is indispensable in optimizing storage projects for safety, efficiency, and scalability.

Industry Applications and Integration

CCS technologies are finding applications across various sectors closely tied to petroleum engineering.

- Hydrogen Production: Reforming natural gas with integrated CCS enables low-carbon hydrogen, supporting cleaner fuels and industrial processes.

- EOR: Injecting captured CO2 into mature reservoirs boosts oil recovery while sequestering emissions.

- Direct Air Capture: Emerging technologies like 8 Rivers’ Calcite process remove CO2 from the atmosphere, complementing industrial capture efforts.

Challenges and Opportunities

Despite its potential, CCS faces hurdles such as high costs, regulatory challenges, and public acceptance. However, ongoing advancements in capture efficiency, storage monitoring, and supportive policies are paving the way for wider adoption. Petroleum engineers, with their technical skills and innovative mindset, are uniquely positioned to overcome these challenges, driving CCS toward mainstream implementation.

Conclusion

"Global CCS Institute's CCS Technologies 2024" underscores the transformative potential of CCS in decarbonizing the energy sector. For the petroleum engineering community, CCS not only offers a pathway to sustainable energy practices but also leverages their core competencies to address climate challenges. As the world transitions to a low-carbon future, CCS stands out as a vital technology for achieving climate goals and securing energy resilience.

For Further Reading

State of the Art: CCS Technologies 2024, Global CCS Institute

Cormorant Clean Energy

CO₂ Capture, Axens

Calcite, 8 Rivers

Carbfix—How It Works

BrightLoop Technology, Babcock & Wilcox

Compact Carbon Capture, Baker Hughes

Anireju Emmanuel Dudun is pursuing a PhD in systems engineering with a concentration in petroleum engineering at the University of Louisiana (UL) at Lafayette. He has interned with Shell and the Department of Petroleum Resources in Nigeria. He has been an SPE member since 2012 and is presently a member of the UL Lafayette PetroBowl team. He was listed on SEG EVOLVE’s 2022 Wall of Fame for his work on subsurface characterization. Dundun has over seven peer-reviewed publications and serves as a technical reviewer for various industry journals. His current area of research includes CO2 sequestration, hydrogen underground storage, and reservoir modeling such as reactive fluid flow in fracture reservoirs. He holds a master’s degree in engineering from UL Lafayette, a second master’s degree in integrated petroleum engineering and production studies from Shell Center of Excellence in Geosciences and Petroleum Engineering, and a bachelor’s degree in petroleum engineering from the University of Benin, Nigeria.

Haruna Inuwa is a senior petroleum engineer and SAP consultant at Dangote Projects. In his current role, he is part of the SAP consultants implementing SAP S/4HANA Production Planning at Dangote Fertilizer. Inuwa holds a BS degree in petroleum engineering from Igbinedion University Okada (IUO), Nigeria and a MTech degree in production and industrial engineering from Sharda University, India. He was a freelance content developer at Great Learning, an educational platform in India. Inuwa’s research interest lies in the application of Industry 4.0 technologies to aid a sustainable energy transition. An active member of SPE, Inuwa led the SPE IUO student chapter to win its first SPE Presidential Outstanding Chapter Award in 2018. He also captained IUO chapter’s PetroQuiz team during the Nigeria Council 2018 Students Technical Symposium and Exhibition held at Nile University, Abuja. Inuwa is the founder of Inspire Young People, a NGO with a focus on career mentorship and educational support.