Maintaining the integrity of gas transmission pipelines is critical for ensuring operational safety, minimizing environmental risks, and reducing economic losses associated with unplanned shutdowns or accidents. Conventional inspection techniques, such as in-line inspection (ILI) tools and hydrostatic pressure testing, face inherent limitations: they provide only periodic measurements, may disrupt operations, and can be cost-prohibitive for remote or inaccessible assets. In contrast, distributed fiber-optic sensing (DFOS) technologies offer continuous, real-time monitoring along the entire pipeline length without interrupting production. Among DFOS approaches, distributed acoustic sensing (DAS) has demonstrated promise for detecting vibrations associated with gas leaks.

Our study investigates an innovative approach using internally deployed fiber-optic cables for DAS-based leak detection—a configuration designed to improve field applicability. Experimental results from controlled laboratory testing illustrate the potential of this approach to enhance leak detectability, support early intervention, and strengthen overall pipeline-integrity management.

How Does Distributed Acoustic Sensing Work?

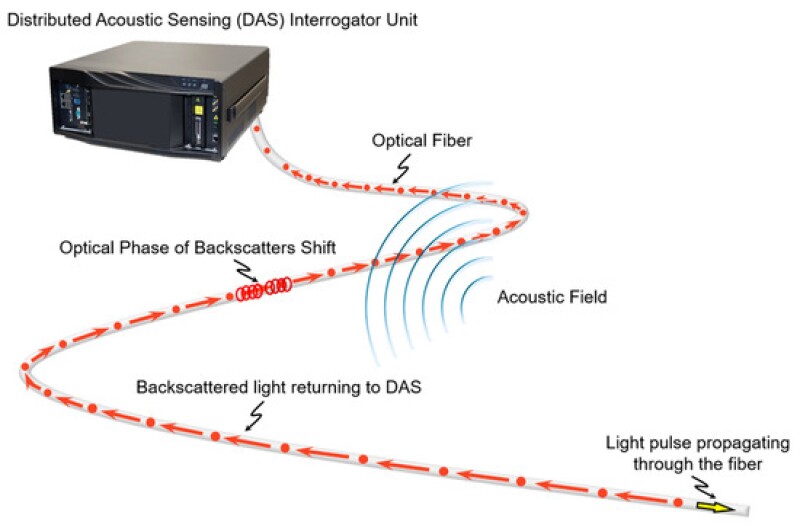

DAS operates by sending coherent laser pulses through an optical fiber and measuring the phase changes in the backscattered light. These phase changes occur in response to strain or vibrations along the fiber caused by external acoustic fields, such as those produced by fluid flow or leak-induced turbulence.

By analyzing these variations, DAS systems can generate high-resolution, distributed measurements of vibration along the entire length of the fiber. This technology effectively turns the fiber into a continuous array of thousands of virtual acoustic sensors, enabling real-time detection of events such as leaks, third-party intrusions, or structural vibrations without the need for discrete sensors along the pipeline. Fig. 2 illustrates the basic operating principle of a DAS system.

Why Is DAS a Promising Technology for Leak Detection?

DAS offers significant advantages for monitoring the integrity of gas pipelines. Unlike traditional inspection methods that provide only periodic assessments and often require service interruptions, DAS enables continuous, real-time monitoring along the entire length of the pipeline. This capability allows operators to detect and localize leaks as they develop, supporting faster response times and reducing the risk of environmental or safety incidents. Also, DAS offers high spatial resolution enabling precise identification of leak locations, even in remote or inaccessible areas where conventional inspection tools are impractical. By providing operators with early warning of leak events, DAS improves the reliability of pipeline operations and supports proactive maintenance strategies, ultimately contributing to safer and more sustainable energy transportation.

Advantages of Internal Fiber Deployment for DAS

While DAS systems are often installed externally along pipelines, internal fiber deployment offers important operational and practical advantages that make it a compelling alternative in certain contexts. Externally installed fibers can suffer from variable mechanical coupling issues, especially in aging or buried pipelines where installation access is limited or where soil conditions change over time. These factors can reduce detection reliability and complicate maintenance.

In contrast, internal deployment places the sensing fiber directly inside the pipeline, allowing it to interact more directly with flow conditions and potential leakage events. It offers practical advantages for certain field scenarios, including the ability to retrofit existing pipelines without major excavation or surface work. This configuration supports practical field applications by offering a cost-effective, less-invasive method for expanding DAS monitoring coverage, particularly in legacy infrastructure or remote locations where traditional external installation would be difficult or cost prohibitive.

How Was the System Tested?

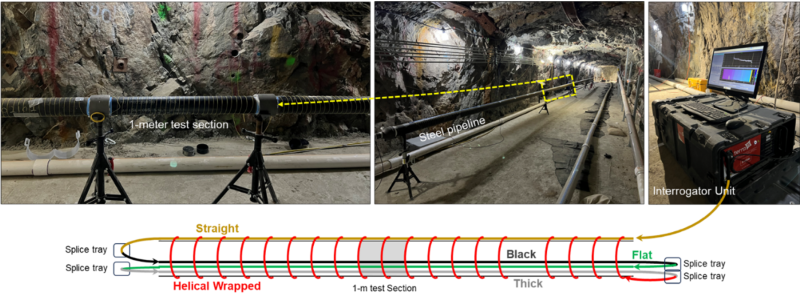

To evaluate the effectiveness of internal fiber-optic deployment for leak detection, we conducted controlled experiments using a 21-m-long steel pipeline with a 4-in. internal diameter. The testing was carried out at the Edgar Mine, the Colorado School of Mines’ experimental facility, which offers a stable, quiet environment ideal for vibration measurements. Its low ambient noise and constant year-round temperature minimize environmental variability, ensuring consistent and reliable data acquisition.

A 1-m section at the center of the pipeline was designed to allow interchangeable test configurations, including introducing controlled leak points of varying sizes and orientations. Leakage simulations were performed by threading calibrated iron fitting reducers into pre-drilled holes, creating repeatable leak diameters of ¼ in., ½ in., ¾ in., and 1 in. (Fig. 3). The experimental setup also included gas flow control systems capable of delivering air at standard velocities of 2, 6, 10, 14, and 18 m/s, allowing us to assess detection performance across a range of realistic operating conditions.

Four different fiber-optic deployment configurations were tested: one external cable taped in a straight configuration along the top of the pipeline and three internally deployed cable types with varying stiffness and jacket designs. Data acquisition was performed using a Terra 15 interrogator unit, configured for high-resolution, distributed vibration measurement along the entire fiber length. Post-processing involved standard deviation reduction, spectral analysis, and energy band methods to identify and characterize leak-induced vibration anomalies. This systematic testing approach enabled direct comparisons between cable types, deployment configurations, leak sizes, flow velocities, and leakage positions.

What Did the Results Show?

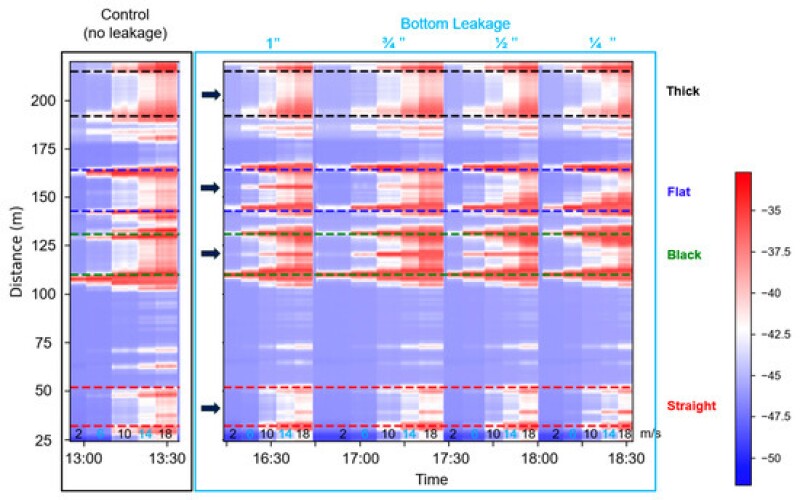

Experimental results showed that several fiber-optic cable configurations were able to detect vibration anomalies associated with controlled leak events. Standard deviation analysis demonstrated that vibration intensity at leak locations generally increased with larger leak sizes and higher flow velocities. Among the internal cables, the lighter and more flexible designs, such as the black and flat cables, consistently produced clearer and more repeatable signatures under these conditions. The thick internal cable showed limited sensitivity across tests, likely due to its heavier, stiffer construction. The external straight-taped cable also detected leak-induced anomalies, with its performance influenced by mechanical coupling quality and installation care. Improved taping enhanced its detection capability. The position of the leak relative to the sensing fiber affected results, with locations closer to the cables producing stronger anomalies. Spectral analysis supported these observations by revealing frequency bands associated with leak-induced turbulence.

Overall, the findings indicate that different deployment approaches can provide leak-detection capability, with variations in signal strength and consistency depending on cable design, installation, leak size, flow conditions, and location (Fig. 4).

What Are the Challenges?

While the study demonstrated that fiber-optic DAS systems can detect leak-induced vibrations under controlled conditions, several practical considerations remain for real-world deployment. One important factor is data management. High-resolution DAS monitoring generates large volumes of data that must be efficiently processed and stored to support timely detection without excessive operational burden. Effective analysis often relies on methods such as standard deviation processing and spectral analysis, supported by appropriate computational resources.

Installation and maintenance also present practical challenges. Ensuring reliable mechanical coupling, pressure integrity at entry points, and long-term durability of the sensing cables is essential for both internal and external deployments. Addressing these considerations will be critical for enabling robust and cost-effective DAS-based leak-monitoring solutions in operational pipeline systems.

What is the Future of DAS in Pipeline Monitoring?

Continued development of DAS technologies offers significant opportunities to advance pipeline-integrity management. Future research will focus on improving data interpretation through advanced signal processing, machine learning, and real-time monitoring platforms that can reliably distinguish leak signatures from normal operational variations. Addressing challenges related to data management, such as efficient storage, processing, and analysis of large, continuous datasets, will also be essential for practical deployment.

Another important area for future work involves understanding how the physical environment and installation conditions of pipelines, such as whether they are buried, supported, or laid on the ground, affect detection sensitivity and signal characteristics. Systematic studies of these variables can help define best practices for deployment and improve the consistency and reliability of leak detection in different field settings.

In addition to leak detection, DAS technologies have the potential to support comprehensive integrity monitoring, including detecting third-party intrusions, structural deformation, or corrosion-related changes in vibrational response. Expanding these capabilities can enable more integrated integrity-management systems that deliver continuous situational awareness over entire pipeline networks.

Conclusion

Our study demonstrated that multiple fiber-optic DAS deployment configurations can detect leak-induced vibration anomalies under controlled laboratory conditions. Results showed that signal strength and consistency varied with cable design, leak size, flow velocity, and installation approach. Internally deployed lighter, more flexible cables tended to produce clearer and more repeatable leak signatures, while the external straight-taped cable also detected anomalies with performance influenced by mechanical coupling quality. The thicker internal cable displayed limited sensitivity across test conditions.

Practical considerations remain important for field deployment, including data management, processing requirements, installation quality, and long-term durability. Addressing these factors will be critical for enabling reliable, real-time DAS-based monitoring solutions that support early leak detection and enhance overall pipeline safety and integrity.

For Further Reading

Recent Advances in Pipeline Monitoring and Oil Leakage Detection Technologies: Principles and Approaches by M. Adegboye, W. Fung, A. Karnik, Robert Gordon University.

Characterization of Gas–Liquid Two-Phase Slug Flow Using Distributed Acoustic Sensing in Horizontal Pipes by S. Ali, G. Jin, Y. Fan, Colorado School of Mines

Leakage Detection Using Distributed Acoustic Sensing in Gas Pipelines by M. Benabid, P. Baumgartner, G. Jin, Y. Fan, Colorado School of Mines

Easy Deployed Distributed Acoustic Sensing System for Leakage Detection in Gas Pipelines by M. Benabid, A. Garcia-Ceballos, G. Jin, Y. Fan, Colorado School of Mines

DASCore: a Python Library for Distributed Fiber Optic Sensing by D. Chambers, National Institute for Occupational Safety and Health, G. Jin, A. Tourei, Colorado School of Mines, et al.

Monitoring Slug Flow Using Distributed Acoustic Sensing Technology with Different Sensing Cable Configurations by A. Garcia-Ceballos, M. Benabid, G. Jin, Colorado School of Mines, et al.

An Introduction to Distributed Optical Fibre Sensors by A. Hartog

Long-Range Pipeline Monitoring by Distributed Fiber Optic Sensing by D. Inaudi, B. Glisic, SMARTEC SA

Distributed Optical Sensing Systems and Methods

Periodic Hydrostatic Testing or In-Line Inspection to Prevent Failures From Pressure-Cycle-Induced Fatigue by J. Kiefner and W. Maxey

Gas Pipeline Leak Noise Measurements Using Optical Fiber Distributed Acoustic Sensing by J. Muggleton, R. Hunt, E. Rustghi, et al.

Overcoming the Challenges and Increasing Value in Fiber Optic Monitoring, Pipeline Technology Journal

Detection of Leak-Induced Pipeline Vibrations Using Fiber—Optic Distributed Acoustic Sensing by P. Stajanca, S. Chruscicki, T. Homann, Bundesanstalt für Materialforschung und—Prüfung (BAM)

A Novel Fiber Optic Based Surveillance System for Prevention of Pipeline Integrity Threats by J. Tejedor, FOCUS S.L., J. Macias-Guarasa, University of Alcalá, H.F. Martins, FOCUS S.L., et al.

Pipeline Deformation Monitoring Using Distributed Fiber Optical Sensor by S. Zhang, B. Liu, Nanyang Institute of Technology, and J. He, Dalian University of Technology

Mouna-Keltoum Benabid is a PhD candidate in petroleum engineering at Colorado School of Mines. Her research focuses on applying distributed acoustic sensing for pipeline-integrity monitoring. She holds MS and BS degrees in petroleum geophysics from the University of Boumerdes, Faculty of Hydrocarbons and Chemistry, Algeria, where she worked on seismic methods for reservoir characterization. Her industry experience includes serving as a testing field engineer with SLB.

Ge Jin is an associate professor of geophysics and co-director of the reservoir characterization project at Colorado School of Mines. His research interests focus on applications of distributed fiber-optic sensing (DFOS) in geoscience and engineering, as well as seismic imaging and machine learning techniques. He has initiated and developed several important DFOS applications, including cross-well strain monitoring, microseismic imaging, production logging, and reservoir characterization.

Jin has an extensive publication record with more than 70 peer-reviewed journal articles, has edited one book, and authored 12 granted patents. His work is well recognized by many professional societies. He received the ARMA Case Study Award in 2025, delivered the AAPG/SEG Distinguished Lecture in 2024, received the Best Paper award at the URTeC conference in 2023 and 2024, and has received honorable mentions for best papers in The Leading Edge and Geophysics. Before joining Colorado School of Mines, Jin worked for 5 years as a research geophysicist at ConocoPhillips. He holds a PhD in geophysics from Columbia University and dual BS degrees in geophysics and computer science from Peking University.

Yilin Fan is an associate professor of petroleum engineering at the Colorado School of Mines, where she also serves as director of the carbon capture, utilization, and storage (CCUS) interdisciplinary graduate program. She serves on the SPE Production and Facilities Advisory Committee and the ATCE Program Committee, and is an associate editor for SPE Journal, Geoenergy Science and Engineering, and SPE Production & Operations, as well as a technical editor for several other leading journals in the field.

Fan’s research focuses on developing innovative solutions for multiphase flow monitoring and metering, flow- assurance prediction and management, distributed fiber-optic sensing applications, pipeline-integrity assessment, and CO2 transportation. Her work emphasizes the critical importance of secure and reliable pipeline transportation in ensuring safe and efficient energy delivery. She leads a state-of-the-art experimental research laboratory equipped with advanced technologies for multiphase flow characterization and pipeline-integrity assessment under realistic field conditions.