We've all heard the hype. AI is transforming industries, disrupting business models, and rewriting the rules of competition. The tech industry has embraced this revolution with remarkable speed. Generative AI adoption jumped from 55 to 75% between 2023 and 2024, with companies achieving a 3.7x return on every dollar invested (Coherent Solutions). Meanwhile, in oil and gas, we're still having conversations about "should we" rather than "how fast can we."

But the thing is, the conversation shouldn't be about copying Silicon Valley's playbook. It should be about learning what works, understanding why some approaches won't translate to our industry, and then adapting intelligently. As young professionals (YPs) in this space, we're uniquely positioned to drive this transformation—if we're willing to question long-held assumptions along the way.

The False Promise of "Just Do What Tech Does"

Let's be clear: directly applying tech's "move fast and break things" philosophy to oil and gas operations overlooks critical differences in our risk profile. The minimum viable product strategy works in tech because failure is relatively cheap. The main cause of startup failure is lack of market need, not catastrophic consequences (CBInsights). When your app crashes, users get annoyed. When our systems fail, people may die, environments may be harmed or destroyed, and communities may suffer for generations.

We operate 20–30-year facilities in environments where a failed algorithm in well control has completely different implications than a failed algorithm in social media recommendations. Our regulatory framework is exponentially more complex, our asset life cycles are measured in decades not product cycles, and we're dealing with physics and geology, not just code and users.

So no, we can't A/B test a subsea installation. But that doesn't mean we can't learn from tech's AI success.

What We Can and Must Learn

1. Data as a strategic asset, not an IT problem

Here's where tech got it right: they treat data as a product. APIs, microservices, real-time accessibility—these aren't just buzzwords. They represent a fundamental philosophy that data should flow freely and be accessible to anyone who needs it to make decisions.

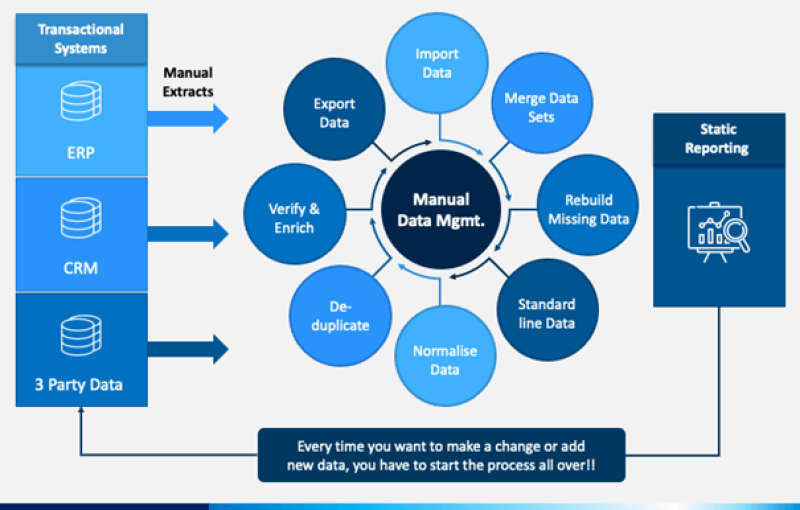

Compare that to the oil and gas industry. How much of your company's critical data is locked in proprietary vendor systems? How many times have you needed information from another department and hit a wall of "that's in a different system" or "we can't export that format?" Even when we can export, we’re often left with incompatible formats or incomplete data sets, forcing us to spend hours on manual workarounds. These aren’t just technical headaches; they’re symptoms of deeper vendor lock-in and data silos, as seen in Fig. 1, that stifle innovation and slow down progress. We've spent decades building these silos, and now we're shocked that AI can't work magic with fragmented, incompatible data.

2. Fail fast, but fail safely

Tech's "fail fast" culture seems reckless to us, and in our operational context, it is. But strip away the Silicon Valley rhetoric and there's a valuable principle: learn quickly from small, controlled experiments rather than betting everything on a perfect plan (Fig. 2).

We can adopt this. We just need to do it smartly. Digital twins, simulation environments, and pilot programs in noncritical operations give us safe spaces to experiment. ADNOC's AR360 solution was first deployed on two reservoirs at Bab and Umm Shaif fields before expanding to more than 30 reservoirs across upstream operations. They didn't roll it out everywhere at once. They tested, validated, learned, and then scaled.

That's "fail fast" adapted for high-consequence industries. Start small, prove value, scale strategically. And if something doesn't work in simulation or pilot? Great, you learned that before it mattered.

3. Cross-functional integration is non-negotiable

In tech, data scientists sit with product teams. In oil and gas? We still have IT departments that operate like separate companies, building solutions in ivory towers and wondering why adoption is poor.

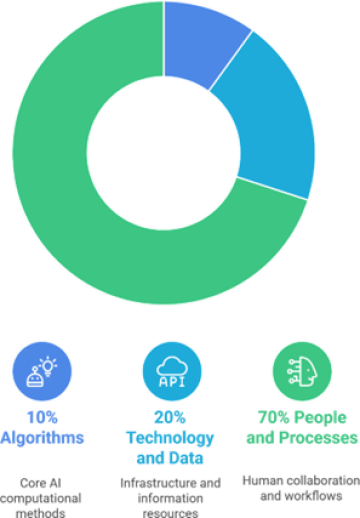

Research shows that AI leaders allocate resources with a 10/20/70 rule: 10% on algorithms, 20% on technology and data, and 70% on people and processes (Fig 3). Seventy percent on people and processes: not technology, and not fancy algorithms.

This means embedding data scientists with drilling engineers, production teams, and reservoir engineers—not creating a "center of excellence" that's disconnected from operations. It means your geoscientist and your machine learning engineer need to speak enough of each other's language to collaborate effectively.

The Essential Role of Young Professionals

Here’s where it gets personal for us as YPs. According to EY, 62% of Gen Z say a career in oil and gas is unappealing, a perception driven by concerns about environmental impact, job instability, and a lack of innovation. Yet, the biggest risk our companies face may not be external, but internal: a deep-rooted cultural resistance to new technology, especially AI that challenges traditional ways of working (EY). As digital natives entering an industry with a deep legacy, we’re not just bridging two worlds; we’re uniquely positioned to lead the transformation, if we’re willing to challenge old assumptions and champion new approaches.

But that's exactly why we're essential. We're not trapped in "we've always done it this way." We're comfortable with continuous learning and rapid technological change. And critically, we'll live with the consequences of the decisions being made today.

So, what's our role?

Be the translator. Learn enough data science to be critical. Teach enough domain knowledge to make data scientists effective. New roles are emerging, such as data integration specialists, AI operations engineers, and digital systems architects that specifically bridge operational technology and information technology (Mane). Position yourself in that space.

Champion the pilots. Volunteer for AI projects. Become the internal case study. When your company is debating whether to try something new, be the person who raises your hand and says, "I'll run the pilot in my area."

Push for standards. Even informally. Start documenting your team's data in consistent formats. Push back when vendors want to lock you into proprietary systems. These small actions compound.

Build the network. Join SPE's Data Science and Engineering Analytics Technical Section. Participate in OSDU forums. Connect with peers across disciplines. Innovation doesn't happen in silos.

Moving Ahead

The results are already visible in companies that get this right. ADNOC deployed over 30 AI tools across its operations, generating $500 million in value in 2023 while reducing CO2 emissions by 1 million tons, equivalent to removing 200,000 cars from the road. Their ENERGYai platform demonstrated 70% improvement in seismic interpretation accuracy. This isn't theoretical, it's happening now.

But here's what makes this achievable: they didn't try to become a tech company. They stayed an energy company that strategically uses technology. They adapted tech principles to their reality; collaborative data platforms, controlled experimentation in safe environments, and heavy investment in the people side of transformation.

That's the playbook. Not "copy Silicon Valley." Not "ignore AI because we're different." But "learn intelligently, adapt thoughtfully, and move decisively."

The future of our industry depends on getting this balance right. And as YPs, we're not just along for the ride, we're the ones who need to drive it. The question isn't whether oil and gas will transform. It's whether we'll lead that transformation or watch it happen to us.

The bridge between tech's AI revolution and oil and gas's operational reality won't build itself. It's time we started building it together—one idea, one collaboration, one bold step at a time.

For Further Reading

Scaling AI for Maximum Impact in Oil and Gas by S. Bhadauria, EY

Digital Transformation in Offshore Oil & Gas: AI Revolution and Industry Impact, Mane

AI in Oil and Gas Market Analysis, Mordor Intelligence

OSDU Data Platform, SLB

The OSDU Data Platform—A Primer, The Open Group OSDU Forum

AI Adoption Across Industries: Trends You Don’t Want to Miss in 2025, Coherent Solutions