Two companies, C&J Energy Services and Seismos, have teamed up to combine their fracture characterization technologies into a single service. They say their technology tandem was recently used in the field by a completions team to customize almost two-thirds of the stimulation stages in a horizontal shale well.

Under the partnership, C&J is responsible for analyzing drilling data from horizontal wells to describe rock properties along the lateral section. Seismos comes in during the hydraulic fracturing phase to take real-time measurements of the fracture network properties.

“They are two totally different measurements, but they are complementary,” said Dale Logan, the senior vice president of marketing at C&J. “We don’t expect them to be a dead-on overlay, but we can see if they make sense with each other.”

When the two data sets do align, it means that the rock-property assessment made with drilling data is corresponding to the responses seen during the well’s treatment phase. Drawing this relationship is especially relevant for perforation clusters placed in a well section where the rock is at the upper end of the hardness index. In these areas, operators can expect more variability in how the rock will break down during pressure pumping.

Houston-based C&J is among a number of service providers using drilling data to describe rock strength to this end. The company’s process, described by Logan in SPE 174839, relies on commonly recorded drilling measurements, including weight-on-bit and differential pressure, to calculate mechanical specific energy (MSE). The MSE figure is then used as a proxy to the rock’s compressive strength, which in turn can be used to address the lateral section’s geomechanical heterogeneity by adjusting each fracture stage’s treatment.

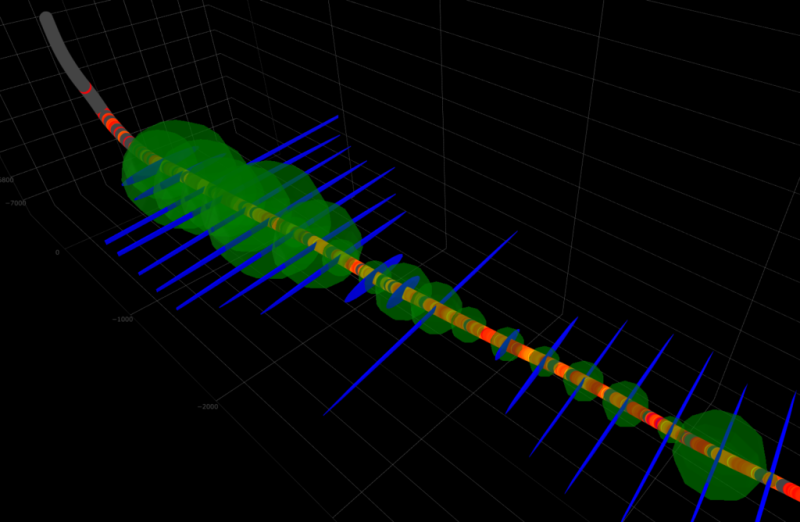

While hydraulically fracturing the well, Seismos uses a wellhead instrument to take direct measurements of how different completion strategies are affecting the fractures as they propagate.

In passive mode, the Seismos system takes advantage of the ambient noise generated by field equipment and captures the acoustic reflections that bounce back from the wellbore and inside its fracture network as its continues to propagate. To enhance its picture of the action, Seismos also has the ability to introduce a noise signal downhole itself.

“We are in the business of analyzing that noise,” said Panos Adamopoulos, the chief executive officer of Seismos. He explained that the acoustic reflections are processed in real time to provide engineers with “a characterization of the fracture network, its complexity, and its ability to transmit hydrocarbons.”

Delivered in stage-by-stage reports, such analysis may indicate that while fracture length may be on target, proppant placement and fracture conductivity are low, factors that might lead to poorer-than-expected production.

C&J and Seismos completed their first three wells together in December 2018 and have several more projects planned in the first half of this year. Two of those wells were used to observe how the distinct data sets corresponded without making any changes to the treatment design. In the third well though, 20 of 35 stages were completed with unique designs. “That’s a lot of variation—but amazing optimization because we saw it become one of their best wells,” said Adamopoulos.

Logan added that, after monitoring the well’s initial stages, the completions manager “was off to the races, making changes on the fly.” C&J and Seismos plan to share details about the pilot work in a technical paper they are submitting for the 2019 Unconventional Resources Technology Conference (URTeC).

An acoustic monitoring device connected to the wing valve of a wellhead. The system relies on ambient noise from the hydralic fracturing operation and its own signals to measure fracture network complexity, conductivity, and reservoir connectivity. Source: Seismos

Real-Time Collaboration

By marrying the rock-property data and with measurements of fracture properties, the goal of the service is to give completions engineers confidence to start tweaking key treatment parameters (e.g. pump rate, proppant volume, or proppant type) from one stage to the next. However, “you need to have the pumping company on your side to do that,” Adamopoulos stressed.

When operators use third-party diagnostic services on the completions site, there is no guarantee that the primary service provider has access to the data or is familiar with what it means. To bridge this gap Seismos’ real-time data will be integrated with C&J’s data vans, which is where most decisions on a fracturing job are put into action.

One way the people in the van can leverage the new diagnostics involves predicting when proppant or sand is likely to get jammed up as it moves into perforations at high rates, a common issue known as a screenout. C&J says its analysis can flag the stages most at risk of a potential screenout, while Seismos’ measurements can detect a sand buildup and issue an early warning. Seismos can also use the acoustic signals to identify the formation’s geomechanical responses such as stress shadowing between stages, or when a breakthrough has occurred and the stages are in full communication.

Founded in 2013 in Austin, Texas, Seismos originally developed its technology to monitor enhanced oil recovery operations. The firm’s pivot to unconventionals helped earn it a $10.5 million equity investment in January. The deal was led by venture group Quantum Energy Partners that, in addition to upstream technology developers, also backs several independent shale producers in the US.