For much of its history, logging-while-drilling (LWD) technologies have followed a long and predictable development cycle: extended design process, slow and cautious operator qualification, and a desirable reliability achieved only after years of exposure in different fields across the world. This conservative approach was understandable and possibly necessary, as these LWD technologies have traditionally been used in environment where the cost of failure is high.

However, things have changed over the past decade or so. The pace at which new LWD technologies move from concept to initial field trials and to commercial deployment has accelerated dramatically. Today, oilfield service companies are delivering new LWD technologies to the field faster than ever before, while achieving higher reliability from the first deployment. This evolution reflects a transformation in how LWD technologies are thought of, engineered, tested, and integrated into drilling systems.

The Old Model: Slow Cycles and Field-Proven Reliability

Historically, development of LWD technology has followed a sequential model that is risk averse. A new tool would move from concept to an engineering prototype, then through laboratory testing with limited capabilities, followed by a limited number of field trial runs. Reliability was later achieved after years of operational exposure and multiple design iterations that overcame the infancy failures.

This approach made sense in an era when modeling capabilities were limited, data gathering and interpretation was unstructured, electronic components were not as advanced, and failure tolerance was low. However, it led to longer timelines, high development costs, and slow learning cycles. Complex technologies such as rotary steerable systems and LWD platforms required years and sometimes a decade before reaching maturity.

A Shift From Sequential to Parallel Development

One of the most significant changes in the development of new technologies has been the shift from sequential development toward parallel engineering workflows.

Today, mechanical design, electronics, firmware, manufacturing, and reliability engineering progress simultaneously as part of technology development. Collaboration platforms allow engineering teams globally to work on different aspects of a tool at the same time, shortening the development cycles. Design decisions are validated earlier in the development through simulations and models. Manufacturing and maintainability constraints are addressed from the prototype itself. Reliability is not an afterthought. Tool firmware, peripheral software, and automation are developed together with the hardware development, ensuring integration from the beginning.

For LWD technologies, this parallel approach has significantly reduced development time by eliminating or reducing late-stage surprises and redesigns that have historically delayed commercialization.

Validation and Verification Processes Changed the Reliability Curve

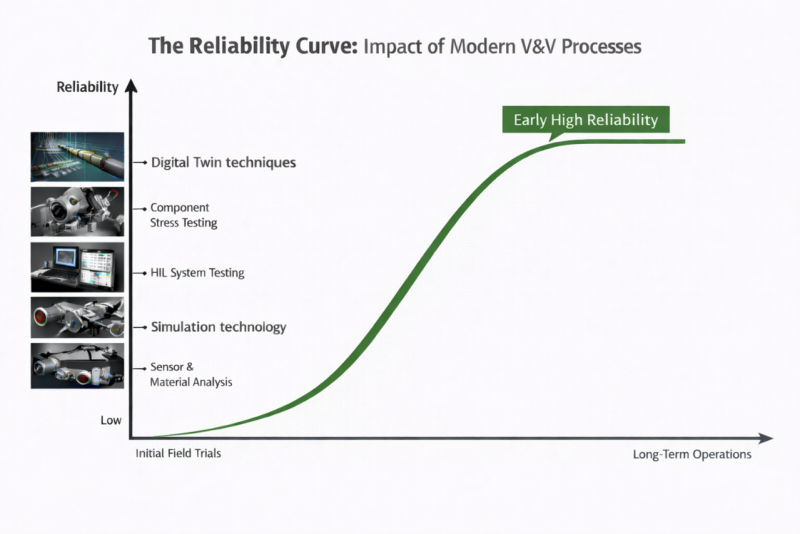

Perhaps the most important enabler of early reliability has been the widespread adoption of modernized validation and verification processes that include creating the digital twin of the technology and undergoing multiple simulations while individually testing different mechanical and electronic subcomponents under extreme load conditions.

Modern LWD tools are exposed across thousands of operating scenarios before the start of actual field testing.

- Simulation techniques such as computational fluid dynamics and finite element analysis are used in the design stage to select the type and grade of different mechanical elements and study their behavior in downhole conditions.

- Highly accelerated life testing of individual electronic components exposed to extreme temperatures and shock simultaneously to identify design weaknesses.

- Different mechanical components are subjected to the pressure/temperature tests, shock test, roll test, and rotating and bending test to ensure they are stress tested for their mechanical integrity.

- Elastomers utilized on the tools are tested in different known chemical properties, developed from a database of known mud properties over the years.

- System engineering techniques such as hardware-in-the-loop simulation are utilized from the beginning of the product life cycle to integrate and validate the firmware with the hardware, allowing for more-robust technology.

- Sensor physics, sensor meteorology, and sensor drift are modeled and tested around the operational boundary conditions to have a strong understanding of the sensor behavior when the hardware they are in are utilized in downhole drilling.

- Different machine-learning techniques are being used to transform sensor responses into downhole subsurface properties, accelerating the development of LWD interpretation, products that previously took years to develop.

In the past, many of the failure modes were discovered only after a few field trials under different operating conditions, as some of these deficiencies showcase only in certain conditions. Today, these issues are identified and designed for before the tool reaches the rig.

The result is a fundamental shift in the reliability curve: instead of improving slowly through operational exposure, new LWD technologies now enter service much closer to their long-term reliability targets (Fig. 1).

Designing for Reliability, Manufacturability, and Maintainability, Not Just Capability

Another major change has been a focus on technology reliability, ability to manufacture, and post-job maintenance, rather than maximizing just performance from the beginning. Engineering teams across all companies now have personnel focused on these additional aspects from the design stage, with teams increasingly prioritizing:

- Simpler mechanical architectures that are easier to manufacture and maintain and less prone to failure

- Reduced number of parts, i.e., fewer number of parts means fewer things to fail

- Higher safety margins indicate that technologies are designed and tested to withstand environmental parameters beyond their stated specifications

- Modular designs that limit failure propagation in worst-case scenario, prevent significant damage, and are easily replaced

- Improved sealing and isolation against mud invasion are achieved through redundant seals made from high-quality materials

- Electronic components have evolved over the years, enabling operation in higher-temperature environments as operators drill deeper into hotter formations

Consistency matters more than peak capability. Tools that deliver high-quality data across long intervals successfully provide far more value than those that promise more but fail early or regularly.

Field Trials With Confidence, Not Caution

The cumulative impact of all these changes can be seen in how new LWD technologies are now introduced to operations. Unlike the past when new LWD technologies were introduced cautiously with the expectation of early failures, today, the first deployments are high-confidence trial runs.

These initial trials are supported by extensive component-level stress testing to system-level integration tests beforehand. Data from early field trials are directly provided to multidisciplinary engineering teams, shortening the timeline for any modifications. What once took years to happen, now happens within months. This tight feedback loop significantly shortens the path from first run to full commercial readiness.

Closer Operator Collaboration

During the development of new LWD technology, oilfield service companies engage with operators far more today than in the past. In many instances the technological requirements, the measurement specifications, the environmental conditions, and reliability expectations are jointly agreed between service companies and operators.

Technologies are sometimes even co-developed with operators defining clear use cases, addressing target markets, providing measurement specifications that satisfy their needs, and defining clear performance expectations (Fig 2). With operators’ skin in the game, the success and commercialization of the technology is a common goal and is more likely to be successful.

What This Means for the Next Generation

For young professionals entering the industry, the core readership of The Way Ahead, this evolution is at the crossroads where the future of LWD-technology innovation will be shaped less by new measurement breakthroughs and more by collaboration of teams across different disciplines.

Mechanical and electrical engineers, petrophysicists, software developers, data scientists, and drilling engineers are no longer working in their silos. Rather, they are working together, connected by data, common models, and aligned objectives.

Faster development and improved early reliability are not opposing goals—they are the natural outcome of this new way of working.

Conclusion

Over the past decade, oilfield service companies have redefined how LWD technologies are developed. Through parallel engineering methodology, modernized validation and verification processes, and system-level integration, new technologies are being developed faster, meet performance expectations from the first run, and demonstrate stable reliability over time.

As the industry continues to demand more precision and greater confidence, this evolution in development philosophy will be as important as the technologies themselves.