Unconventional resources have transformed the landscape of the oil and gas industry. The primary oil recovery factor ranges from 2–8% for the various shale plays throughout the US. Hence, it is imperative to develop the vast potential of unconventional reservoirs and increase the recovery factors beyond primary depletion by implementing IOR/EOR methods. This article describes the role of effective reservoir management and summarizes the detailed review of the advances in IOR/EOR technologies applied to unconventional oil reservoirs, as performed by the Energy Industry Partnership Team (EIP) at the University of Houston (Balasubramanian et al. 2018). That review included:

- A thorough review of the pertinent published literature on IOR/EOR

- Results of EOR application to unconventionals shared by various operators in their investor presentations and from press reports

- Classifying IOR/EOR studies as laboratory experiments, numerical modeling, and field laboratory trials (pilots)

- Analysis of field trials based on the representative shale plays.

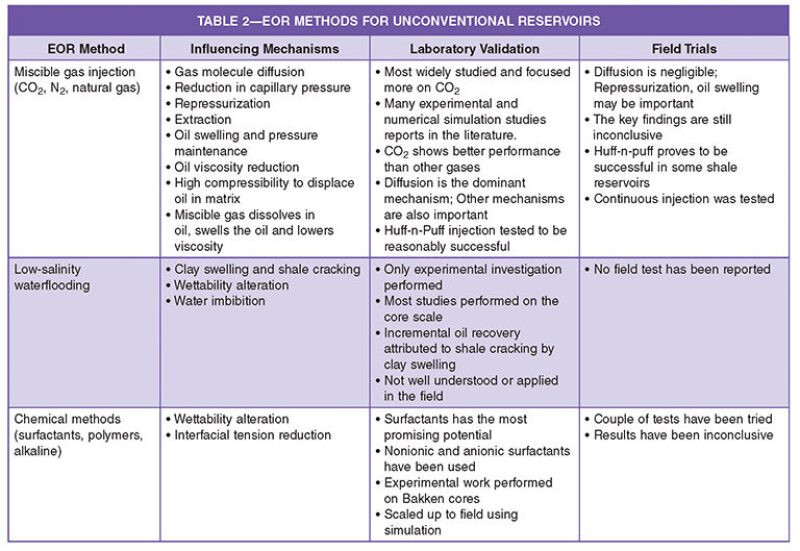

Most studies performed for the application of EOR technologies to unconventional oil reservoirs have been limited to experimental investigations and numerical simulation studies. The research revealed that miscible gas injection (produced field gases, CO2, etc.) is the most promising method among the EOR techniques, including miscible gas, waterflooding, surfactant, chemical, and polymer. Experimental studies showed the following:

- CO2 injection had the highest potential of improved recovery in unconventionals followed by produced gas injection. Surfactant injection showed the next best potential to increase oil recovery by altering the wettability of rock in laboratory experiments.

- The produced field gas injection pilots showed that sufficient injectivity was achieved mainly due to the injection-induced fractures and did not exhibit any significant effect of diffusion.

- Conformance control remains a big challenge due to the channeling of the gas through the fractures.

- Produced field gas injection pilots in the Eagle Ford formation have demonstrated the greatest success in increasing oil recovery.

- Many inconsistencies exist between laboratory investigations and field trials that need reconciliation and further research to bridge the gap.

- This methodical study elicits the learnings and challenges from the application of different IOR/EOR technologies to unconventionals at various scales (micro to macro to field scale). In addition, ideas for future research are recommended to improve the understanding of the complex mechanisms of EOR in unconventional oil reservoirs.

Unconventional resources have changed the landscape of oil and gas industry in the US and the world. Oil production from unconventional tight oil reservoirs have accounted for more than 50% of total oil production in the US in the recent years. Todd et al. reported that unconventional oil reservoirs contributed to more than a 4 million B/D increase in production between 2011 and 2014.

The primary recovery from unconventional oil reservoirs is predicted to be less than 10%, ranging anywhere from 2 to 8% for the various shale plays throughout the US. It is well known that individual well production has a steep decline before leveling off at a low rate. Infill drilling is a current practice to get short-term increase in production. It is not always economic to drill and complete new wells with long laterals.

To date, understanding of EOR in unconventional plays is in its embryonic stage due to poor understanding of the geological constraints on reservoir performance. Definitions of key geological parameters that influence primary recovery are understood to some extent; however, the same in relation to EOR or secondary recovery has not been performed successfully. As the mechanism of EOR is better understood, geological parameters that define the “sweet spot” for a secondary recovery process will simultaneously need to be established. For EOR, industry is still chasing the similar geological characteristics that makes a primary recovery successful, e.g., fractures and brittleness. These parameters may be different for EOR. An integrated field laboratory study will help advance knowledge with practical results.

Rigorous reservoir characterization is necessary to provide realistic geomodels and perform more accurate dynamic simulation of EOR processes. As in conventional reservoirs, reservoir characteristics, including fracture network and fluid properties must be favorable for EOR methods. Lab studies, along with field production data analysis and simulation work, suggest that fluid mobilities within the reservoir are controlled by fractures. Key concepts for EOR applicability in unconventional reservoirs include:

- Fault location, fracture networks, complexity, and density that dictate EOR fluid permeation and hydrocarbon extraction

- Production logs providing insights into fluid distribution

- A variety of log data (resistivity, microimaging, ultrasonic) for fracture characterization

- PNL assisting with mineralogy, lithology, and fluid saturations

- Microseismic data helping induced fracture network distribution and stimulated reservoir volume

- Pressure monitoring, fluid communication tests, stimulation pressure tests, and pulse tests that help identify fluid communication paths between wells, communication due to frac hits

- Use of tracer tests as a cost-effective means of identifying fluid flow paths

- Containment of injection gas

- API gravity, gas-to-oil ratio, bubble point pressure, first contact miscible pressure, and fracturing pressure

- Well completions strategy also plays an important part for an EOR application:

- Design of the injection well completions

- Completions being targeted to the injection test and monitoring plan to understand how fluids are moving

- A detailed history of the production and completions of the subject well and the surrounding wells

- A conformance control plan considering the quality of the completions

Status of EOR in Unconventional Oil Reservoirs

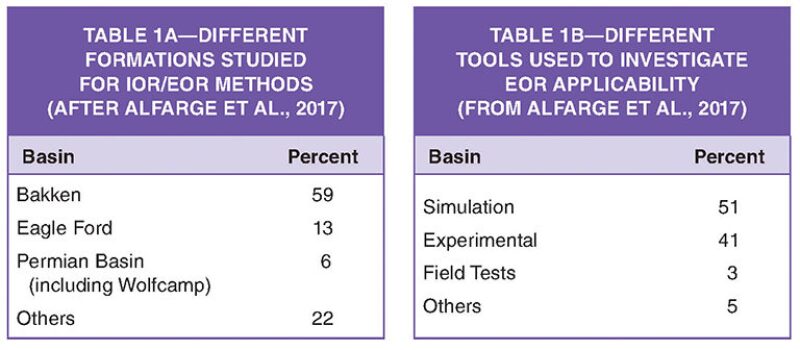

EOR methods in unconventional reservoirs are quite different from those in conventional reservoirs due to the complex and poor quality properties of the plays. Most studies have been limited to experimental work, mathematical approaches, and numeric simulation. A few pilots have been conducted in North Dakota and Montana in the Bakken formation (Wood et al. 2011; Schmidt et al. 2014; Todd et al. 2016). A range of conclusions has been presented by the different researchers on the applicability and understanding of EOR to unconventional oil reservoirs. The ultra-tight matrix and high conductivity of the natural fractures are two important factors that impair success of unconventional EOR methods. Table 1A shows a snapshot of the different studies that have been performed on the various shale and tight oil formations. Table 1B shows the different tools that have been used to investigate IOR/EOR methods applicability (Alfarge et al. 2017). Field trials for EOR have been limited in the Permian Basin Wolfcamp formation.

The EOR methods that have been most investigated for applicability in the unconventional reservoirs are summarized in Table 2.

EOR Field Trials

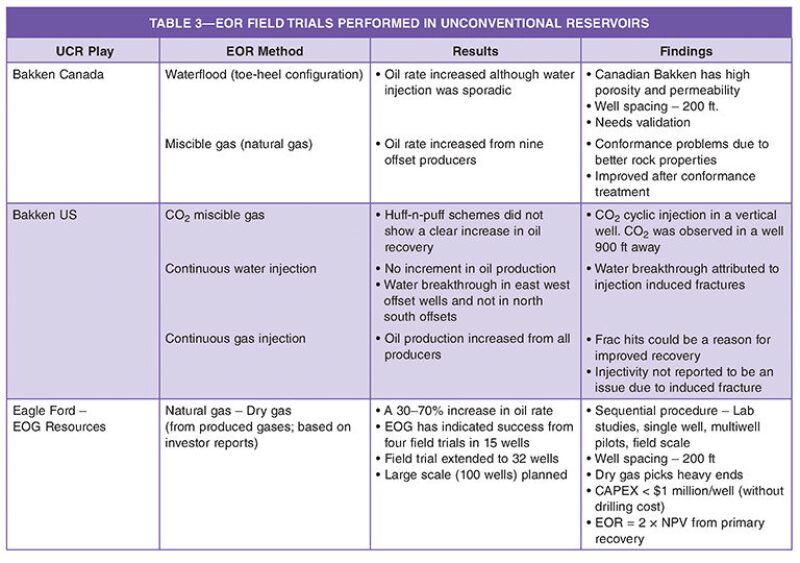

Most of the field trials or pilots conducted using waterflood, miscible gas, CO2, and natural gas have been performed in the Canadian Bakken, Bakken, and Eagle Ford formations. Field trials for EOR have been limited in the Permian Basin Wolfcamp formation. The field trials in the Bakken are distributed between Canada and US (Table 3).

Conventional/Unconventional EOR Ratios

Note that for a conventional reservoir (depletion drive, light/medium gravity oil in the Permian Basin), often there is a relationship between SR (secondary recovery due to water injection) and PR (primary recovery), and TR (tertiary or EOR recovery) and a sum total of (PR+SR). The underlying causes for the SR value for a reservoir are similar to the ones for the PR process, e.g., reservoir and fluid properties, heterogeneity, continuity, and well locations. Similar observations are also made when comparing a TR value (for CO2 flooding) with respect to its (PR+SR) value. Although it would be incorrect to say that SR or TR will always be higher if PR is greater, in many cases in my opinion, this type of relationship is true for the conventional reservoirs in the Permian Basin. If we apply similar logic to an unconventional reservoir, to maximize the total recovery, we must not only focus on EOR but also continue to stretch the envelope in terms of increasing PR values.

Challenges/Limitations/Lessons Learned

- Most investigations for EOR in unconventional reservoirs have been limited to experimental studies and numerical simulation, resulting in wide gaps between the micro scale (lab scale) and macro scale (field trials) studies for the different EOR methods in unconventional reservoirs.

- CO2 EOR ranked as the most suitable method over natural gas in the laboratory studies, but field trials showed more success with natural gas or enriched natural gas.

- Experimental studies concluded that CO2 diffusion was the mechanism for improved recovery, whereas the pilot tests did not show a clear indication on the field scale.

- Earlier studies concluded that injecting miscible gas by huff-n-puff protocol might be more beneficial than continuous injection.

- Understanding the length of the soak time (extent of diffusion) vs. area of gas contacting the rocks (stimulated rock volume) is critical to EOR success.

- It is unclear if high intensity of natural fractures played a role in the conformance problems, although this was not observed in the Canadian Bakken.

- It is essential to conduct studies to integrate all tools of detailed reservoir characterization and geomodeling, lab, dynamic simulation, and pilot tests to advance the understanding of the applicability of each IOR/EOR method to unconventional reservoirs.

- Improved understanding of the petrophysical, geological, and geochemical conditions of the reservoir rock help in designing the best development strategy of these tight resources.

- Horizontal wells with multistage fractures are used for unconventional development. The effective number of wells and fracture stages are not quite well understood.

- Horizontal wells are currently placed in an equally spaced fashion, which leads to variations in total production per well. Developing a standard/metric to place fractures and wells has always been challenging.

Conclusions

- The industry is optimistic about the future of EOR in tight oil formations. There are significant opportunities for oil mobilization and production using produced field gas and CO2 injection under appropriate conditions.

- IOR and EOR are essential to improving the primary recovery factor that ranges from 2% to 8% in unconventional oil reservoirs.

- The research revealed that miscible gas injection (produced field gases, CO2, etc.) is the most promising method among the EOR techniques (miscible gas, water flooding, surfactant, chemical, and polymer).

- Experimental studies showed that CO2 injection had the highest potential of improved recovery in unconventionals followed by produced gas injection followed by surfactant injection.

- Produced gas injection pilots in the Eagle Ford formation have demonstrated the greatest success in increasing oil recovery.

Further Research

Ideas to be considered for future field trials include:

- Advanced gas injection strategies such as cyclic gas injection in areas of better permeability and huff-n-puff gas injection in regions of very low permeability (Zuloaga et al. 2017)

- Effective fracture placement by utilizing technologies to differentiate brittle vs. ductile rock (Alzahabi et al., 2015, Bateman, R. et al. 2016, Ozkan, E. et al. 2009).

- Smart injection technologies considering the variation in rock properties and moving from equally spaced wells and fractures to more efficient well spacing and fracture placement.

- Enough long-term data to ascertain that the recovery factor is being increased than just accelerating production.

Acknowledgments

I sincerely thank the research work performed by the Energy Industry Partnership Team at the University of Houston Petroleum Engineering Department. The key members of the team included S. Balasubramanian, P. Chen, S. Bose, A. Alzahabi, and G. C. Thakur (director). In particular, S. Balasubramanian played the main role in documenting OTC 28973, which served as the foundation of the subject paper.

References

- Balasubramanian, S., Chen, P., Bose, S., Alzahabi, A. and Thakur, G.C. (30 April–3 May 2018). Recent Advances in Enhanced Oil Recovery Technologies for Unconventional Oil Reservoirs. OTC 28973-MS

- Alfarge, D., Wei, M., and Bai, B. (23 April 2017). IOR Methods in Unconventional Reservoirs of North America: Comprehensive Review. Society of Petroleum Engineers. doi:10.2118/185640-MS

- Alzahabi, A., Soliman, M., Al-Qahtani, G, Bateman, R, and Asquith, G. (2015). Fracturability Index Maps for Fracture Placement in Shale Plays. Hydraulic Fracturing Journal, Volume 2-Issue No.1, pp. 8–18. ISSN 2373–8197.

- Bateman, R., Alzahabi, A. M., and Soliman, M. Y. (24 October 2016). Resistivity Transform Indicates ‘Fracturability’. AOGR. http://www.aogr.com/web-exclusives/exclusive-story/resistivity-transform-indicates-fracturability

- Ozkan, E., Brown, M. L., Raghavan, R. S., and Kazemi, H. (1 January 2009). Comparison of Fractured Horizontal-Well Performance in Conventional and Unconventional Reservoirs. Society of Petroleum Engineers. doi:10.2118/121290-MS

- Schmidt, M., and Sekar, B. K. (1 January 2014). Innovative Unconventional2 EOR-A Light EOR an Unconventional Tertiary Recovery Approach to an Unconventional Bakken Reservoir in Southeast Saskatchewan. World Petroleum Congress.

- Todd, H. B., and Evans, J. G. (5 May 2016). Improved Oil Recovery IOR Pilot Projects in the Bakken Formation. Society of Petroleum Engineers. doi:10.2118/180270-MS

- Wood, T., and Milne, B. (2011). Waterflood potential could unlock billions of barrels: Crescent Point Energy.

- Zuloaga, P., Yu, W., Miao, J., Sepehrnoori, K. (2017). “Performance evaluation of 〖CO2 Huff-n-Puff and continuous injection〖CO2 injection in tight oil reservoirs,” Energy, 134, 181–192.