With an intent to reduce greenhouse gas emissions, oil and gas companies are exploring different ways to become carbon neutral in the next 20 to 30 years. To achieve this target, carbon capture and storage (CCS) plays a vital role, with the help of petroleum engineering and geoscience skills. Companies need to leverage existing assets and technology to establish a successful low-carbon venture technology. Strategic areas that companies could potentially invest to succeed in a low-carbon venture technology are

- Direct air capture

- CO2 enhanced oil recovery (EOR) in conventional and unconventional reservoirs

- CO2 EOR in residual oil zones (ROZ)

- CO2 storage

- Use of CO2 in plastics, biological conversion, etc.

Table 1 shows the sources of CO2 emissions during energy production, transportation, and consumption. The captured carbon can be disposed of in different ways:

- Direct Geological Storage

- Injection into deep saline aquifers

- Injection into depleted oil and gas reservoirs

- CO2 Utilization

- EOR

- EOR in tight oil reservoirs, ROZ, and transition oil zone (TOZ)

- Other possible industrial uses

| CO2 Emission Sources | Sources | Emissions |

| Oil and gas production | Combustion and rotating equipment, flaring, venting | CO2 and methane |

| Transportation | Pipelines, vessels, vehicles | CO2 and methane |

| Refining and petrochemical production | Heaters, boilers | Primarily CO2 |

| End use | Use of gasoline, diesel, and coal | CO2 |

Table 1—CO2 emission sources.

Anthropogenic CO2 (CO2 associated with human activities) projects were successful in the past and a few are listed in Table 2.

| Project | Operator | Location | CO2 Source | Size (million ton/yr) |

| Uthmaniyah | Saudi Aramco | Saudi Arabia | Hawiyah NGL plant | 0.8 |

| Abudhabi ESI -Phase 1 | Al Reyadah (ADNOC and Masdar) | UAE | Emirates steel Plant | 0.8 |

| Santos Basin | Petrobras | Brazil (Offshore) | NGL plant-FPSO | 1.0 |

| Sleipner | Statoil | North Sea | Gas field (9% CO2) | 0.85 |

| Petra Nova | NRG & Nippon (Japan) | Houston, Texas | Post-combustion CO2 - power plant | 1.4 |

| Gorgon | Chevron | Australia Barrow Island | Natural gas processing | 3.4–3.8 |

Table 2—Some of the successful anthropogenic CO2 projects (Global CCS Institute, 2018).

Successful Field Projects

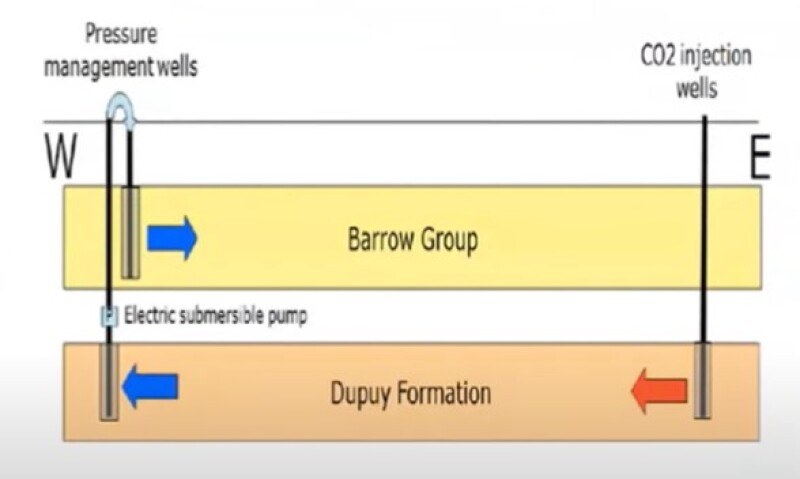

Gorgon CO2 Injection Project. Chevron’s Gorgon CO2 injection project in Northwest Australia is one of the largest CO2 injection projects in the world. Gas that is being produced from the formation contains CO2, which is separated, compressed, and geologically stored in the Dupuy formation. The integrated facility of the Gorgon project can be seen in Fig. 1. Dupuy formation is a Jurassic saline reservoir, deep beneath Barrow Island (Flett et al., 2008). There are nine CO2 injection wells and 4 water production wells to manage the reservoir pressure (pressure management wells).

When CO2 gets injected and the pressure builds up, water production wells are evacuating water so that the accumulation of high pressure gets released. The produced water is being injected into a different formation, as shown in Fig 2. A 3D-seismic analysis was conducted as a function of time to observe how plumes are forming and growing. There are few observation wells equipped with downhole pressure gauges to monitor pressure readings continuously. As a result of this effort, 3.4–4.0 million tons/year of CO2 is being injected into the Dupuy formation and a significant cut in the overall CO2 emissions was observed. Also, an integrated reservoir surveillance plan was adopted to monitor the injected CO2 and study the subsurface uncertainties (Denney, 2013).

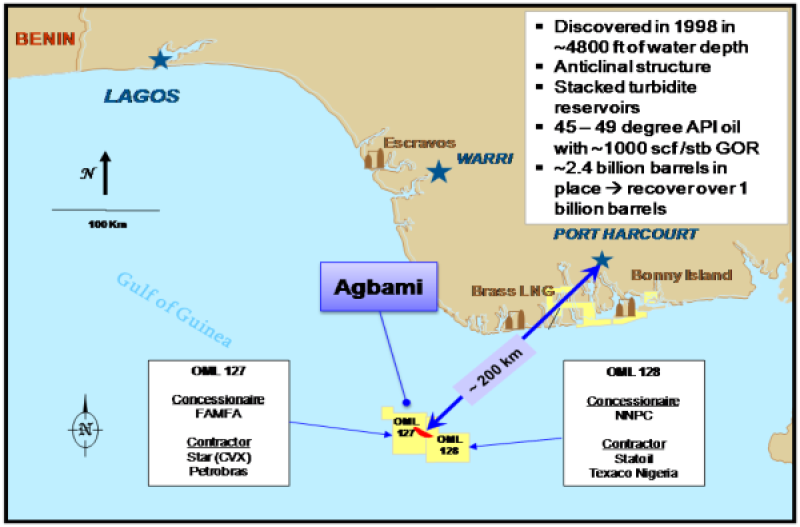

Agbami Oilfield Miscible Natural Gas Injection Project. Agbami field is a $5 billion deepwater natural gas injection project in Nigeria, which holds about 1 billion bbl of recoverable oil. The field was discovered in 1998 and has been producing for the past 12 years. All the produced gas from the field is being injected back into the formation and no gas is being flared. The FPSO vessel in the Agbami field layout (Fig. 3) was built by South Korea’s Daewoo Shipbuilding and Marine Engineering. The field (Fig. 4) is producing around 220,000–240,000 bbl/day of light, sweet crude with an average value of 47 °API.

The bottom of the reservoir consists of water injection wells and the top of the reservoir consists of natural gas injection wells. The gas is being injected at the top pushing the oil down and water is being injected at the bottom and pushing the oil up. This process is known as the “Double Displacement Process” and the oil gets squeezed out of the reservoir by the creation of an effective drive mechanism. Oil and the injected gas are miscible in first contact, and thus miscible gas displacement process is taking place effectively in the field.

CO2 Injection Projects

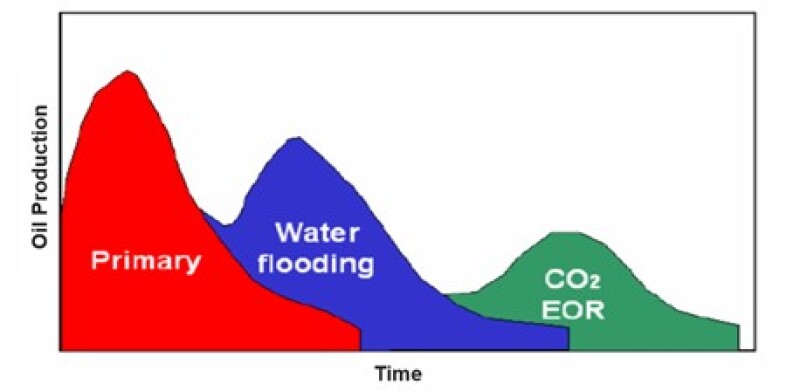

CO2 EOR is a proven process, and more than 166 CO2 EOR projects are currently active around the world producing more than 450,000 bbl of oil per day (McGlade, 2018). These numbers are expected to increase to more than 1.2 million bbl and 1.64 million bbl of oil per day in 2030 and 2040, respectively (IEA, 2019). During the tertiary recovery phase i.e., CO2 EOR (Fig. 5), CO2 injection helps in repressurizing the reservoir and with miscible displacement generates significant incremental oil production.

The first notable CO2 EOR project is the SACROC project in the Permian Basin (Crameik and Plasssey, 1972) and the first commercial-scale anthropogenic CO2 EOR project is Petra Nova, in Texas (2017). Technically, SACROC was the first anthropogenic project started by Chevron in 1972 in the US as CO2 from the neighboring gas plants was collected and transported to the field for CO2 EOR. Chevron, Denbury Resources, Devon Energy, ExxonMobil, Kinder Morgan, and Occidental Petroleum are some of the major companies performing CO2 floods.

CO2 EOR/Storage Challenges

Technical:

- Sweep efficiency improvements

- Well injectivity improvements

- Leakage and concerns along the faults

- Fractures in the wells

- Retention and recycling of CO2

Operational:

- Corrosion

- H2S handling

- Surveillance and monitoring

- Water alternating gas (WAG) optimization

- Storage development plan

Commercial/Social:

- Oil price

- CO2 price

- Tax incentives in different countries (45Q in the United States)

Currently, the industry is injecting more pore volumes of CO2 than earlier. There is more emphasis on maintaining wellbore conditions and improving sweep efficiency. Companies are targeting ROZ, located below oil/water contact and far from the main pay zone (Harouaka et al., 2013). Chevron, Hess, Oxy, and ExxonMobil have their ongoing CO2 EOR ROZ projects in the Permian Basin in San Andres pay zone (Melzer et al., 2006). Various EOR field trials are being performed in the unconventional reservoirs, particularly in Bakken and Eagle Ford formations (Thakur, 2019).

Conclusion

CO2 EOR is a proven technology and it has demonstrated success over the past 50 years in conventional reservoirs. Anthropogenic CO2 capture and storage projects for EOR are growing and being implemented all over the world. CO2 and natural gas EOR for unconventional reservoirs has the potential to double the recovery factor. There is additional potential for deep saline aquifers and ROZ/TOZ in Permian Basin. Retention of CO2 is a concern that most companies have, and we must work as a multidisciplinary team, including geoscientists, field operations personnel, environmental scientists, and others to address them. By running injection profiles and pressure tests and having a rigorous injection well management and surveillance approach, companies can eliminate this concern. CCUS and CO2 EOR can help to meet the demand for oil and gas in the future. According to the Global Carbon Capture and Storage Institute, there are currently 23 large-scale CCS facilities in operation or under construction around the world, to capture around 40 million tons of CO2 per year.

References

Crameik, T. D., and Plassey, J. A. 1972. Carbon Dioxide Injection Project Sacroc Unit, Scurry County, Texas. American Petroleum Institute.

Denney, D. 2013. CO2-Sequestration Projects Adding Value. JPT 65 (07). https://doi.org/10.2118/0713-0131-JPT

Flett, M. A., Beacher, G. J., Brantjes, J., et al. 2008. Gorgon Project: Subsurface Evaluation of Carbon Dioxide Disposal Under Barrow Island. SPE. https://doi.org/10.2118/116372-MS

Global CCS Institute, 2018. The Global Status of CCS.

Harouaka, A., Trentham, B., and Melzer, S. 2013. Long Overlooked Residual Oil Zones Are Brought to the Limelight. SPE 167209-MS. https://doi.org/10.2118/167209-MS.

IEA, IEA, EOR production in the New Policies Scenario, 2000-2040.

Leamon G., 2011. Site Selection–Gorgon, Carbon Dioxide Injection Project. Presentation at CCS in CDM Workshop, Abu Dhabi, 7–8 September.

McGlade, C., Sondak, G; and Han, M. 2018. Commentary: Whatever Happened to Enhanced Oil Recovery? IEA Newsroom. 28 November.

Melzer, L. S., Kuuskraa, V. A., and Koperna, G. J. 2006. The Origin and Resource Potential of Residual Oil Zones. SPE 102964-MS. https://doi.org/10.2118/102964-MS

Odusote, F. 2013. Deepwater Nigeria Field Development: Challenges, Best Practices, and Lessons Learned from the Agbami Field. SPE 167534-MS. https://doi.org/10.2118/167534-MS

Olalotiti-Lawal, F., Onishi, T., Datta-Gupta, A., et al. 2018. Post-Combustion CO2 WAG Pilot in a Mature Field: Model Calibration and Optimization. SPE-191472-MS. https://doi.org/10.2118/191472-MS

Orr, F. M. 2018. Carbon Capture, Utilization, and Storage: An Update. SPE-194190-PA. https://doi.org/10.2118/194190-PA

Sas, E., Pere, J. M., Savy, P., et al. 2008. "Flexible Pipe Design Optimization for West Africa Deepwater: Agbami Production Riser Case Study." Paper presented at the Offshore Technology Conference, Houston, Texas, May. https://doi.org/10.4043/19250-MS

Thakur, G. 2019. Enhanced Recovery Technologies for Unconventional Oil Reservoirs. JPT 71 (09). https://doi:10.2118/0919-0066-JPT

[The article was sourced from the author by TWA editor Vikrant Lakhanpal.]