The Past: Origins and Early Development

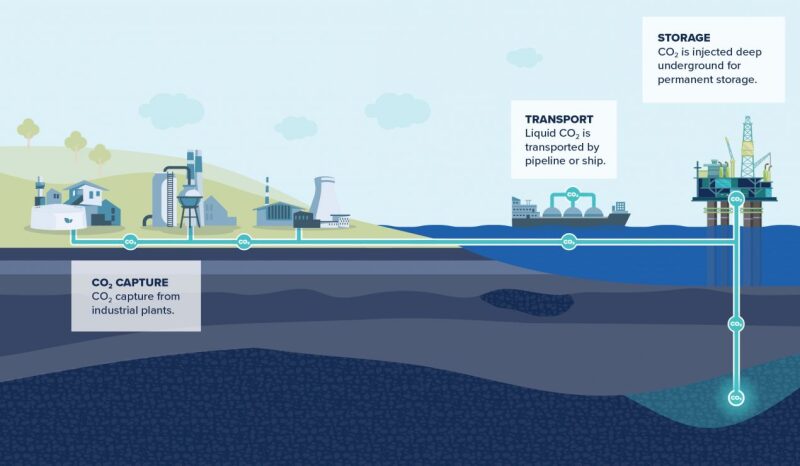

The concept of carbon capture and storage (CCS) originated in the mid-20th century, primarily within the oil and gas industry. Initially, CCS was employed to enhance oil recovery by injecting CO2 into oil fields, thereby increasing reservoir pressure and facilitating the extraction of additional crude oil. The environmental implications of this technique soon garnered attention, leading scientists to explore its potential for capturing CO2 emissions from industrial sources such as power plants and factories and sequestering them underground to mitigate atmospheric release (Fig. 1).

Early CCS development encountered significant obstacles, including high costs, substantial energy requirements, and unproven scalability. Despite these challenges, the 1970s and 1980s marked considerable progress, with pioneering commercial projects demonstrating the viability of geological CO2 storage. Advances in drilling technology, subsurface monitoring, and materials science began to address initial barriers, incrementally improving the feasibility of large-scale deployment.

As global awareness of climate change intensified, interest and investment in CCS surged. These early innovations laid a robust foundation for CCS to evolve into a pivotal component of international strategies aimed at reducing greenhouse gas emissions, underscoring its transformative potential in sustainable industrial practices.

The Present: Current Applications and Challenges

CCS is integral to global climate change mitigation efforts, with many large-scale projects now operational. These initiatives target reducing CO2 emissions from power plants, cement factories, and steel mills by capturing CO2 and storing it in geological formations like depleted oil and gas reservoirs or deep saline aquifers. CCS is particularly valuable for reducing emissions from hard-to-decarbonize industries and, when combined with biomass energy, can achieve negative emissions.

Current CCS techniques include chemical absorption, where solvents like ethanolamine capture CO2 in a dual-column system, and physical separation methods such as adsorption (using activated carbon), absorption (using Selexol), cryogenic separation, and dehydration and compression, are primarily used in natural gas processing. Oxy-fuel combustion burns fuel with pure oxygen, producing flue gas mainly composed of CO2 and water vapor, facilitating CO2 capture. Membrane separation employs selective barriers to capture CO2 and is in the demonstration stage for natural gas processing. Emerging technologies like calcium looping using lime and chemical looping using metal oxides capture CO2 through high-temperature reactions.

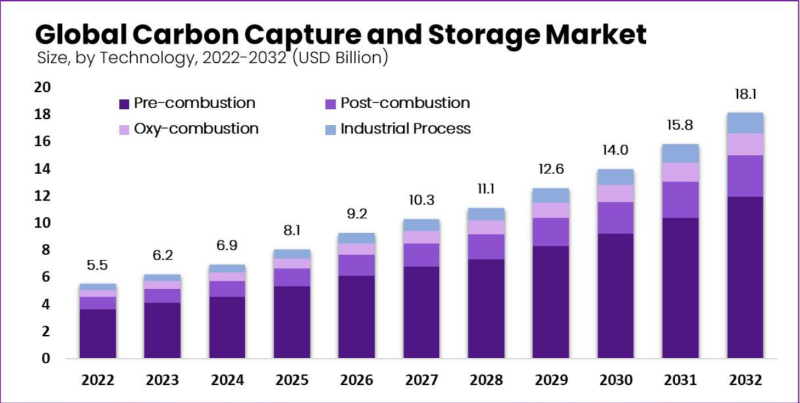

However, the widespread adoption of CCS faces several challenges. The high cost of storage technologies, along with the need for substantial infrastructure investment, remain significant barriers. Public concerns about the safety and long-term stability of CO2 storage sites need to be addressed through rigorous monitoring and regulatory frameworks. Despite these challenges, the global CCS market is projected to grow significantly from 2022 to 2032 (Fig. 2).

Distinguishing between CCS and carbon capture, utilization, and storage (CCUS) is increasingly important. CCUS not only stores CO2 but also utilizes it in industrial processes, adding economic value and enhancing the overall feasibility of carbon capture initiatives. Future efforts focus on cost reduction, efficiency improvement, and integration with renewable energy.

The Future: Innovations and Opportunities

The future of CCS is promising and essential for meeting global climate goals. Innovations in capture technologies, such as more efficient and less energy-intensive methods, are crucial for reducing costs and enhancing feasibility. The integration of artificial intelligence and machine learning could optimize CCS processes, from capture to storage monitoring, further improving efficiency and effectiveness.

Emerging applications, such as direct air capture (DAC), which involves capturing CO2 directly from the atmosphere, offer new avenues for reducing global greenhouse gas levels. DAC, combined with reliable storage solutions, could play a pivotal role in reversing the trend of rising atmospheric CO2 concentrations. Developing a global CCS infrastructure including CO2 transportation networks and international collaboration on storage sites is vital for broader implementation. This approach is particularly important for countries with limited geological storage capacity or those facing financial and technological constraints.

Addressing these challenges opens opportunities for young professionals to contribute to innovative solutions, ensuring CCS remains a key component in global climate strategies. Future initiatives should prioritize reducing costs, enhancing efficiency, and integrating with renewable energy sources to maximize the potential of CCS.

Conclusion

The evolution of CCS from its origins in the oil and gas industry to a central climate mitigation tool highlights its transformative capacity. Despite technological advancements, CCS faces significant challenges, including high costs, substantial infrastructure investments, and public concerns about CO2 storage safety and stability. Distinguishing CCS from CCUS is crucial, as CCUS adds economic value by integrating CO2 into industrial processes.

Future efforts should prioritize developing more-efficient, less energy-intensive capture technologies, optimizing processes with artificial intelligence, and creating a global CCS infrastructure. This approach is vital for countries with limited geological storage capacities. Addressing these challenges opens avenues for innovation, ensuring CCS remains key to global strategies for reducing greenhouse gas emissions and achieving climate goals. Prioritizing cost reduction, efficiency improvements, and renewable energy integration will enable CCS to realize its potential in a sustainable, low-carbon future.

For Further Reading

CCS Explained: The Basics. Global CCS Institute.

Can Direct Air Capture Deliver? by B. Wright, JPT.