Hydrogen could supply 10–20% of global energy needs by 2050, according to the International Energy Agency (IEA), and oil and gas companies are investing in pilots and commercial projects. For engineers, understanding hydrogen’s technical, economic, and career implications is important.

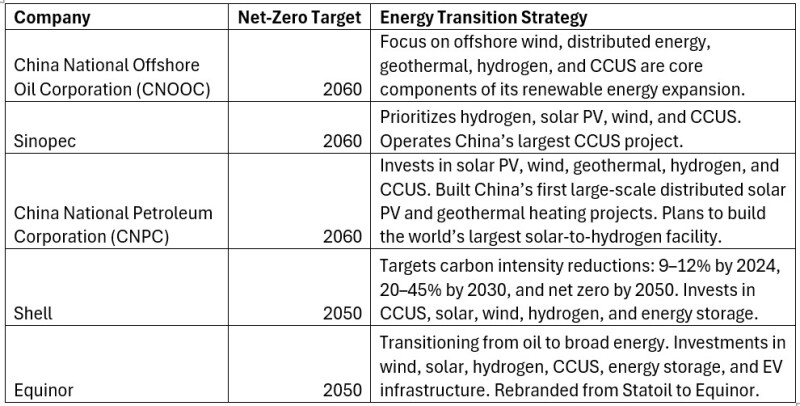

This article highlights how oil and gas companies are leveraging existing infrastructure, expertise, and emerging technologies to lead in the development of the hydrogen economy (Table 1).

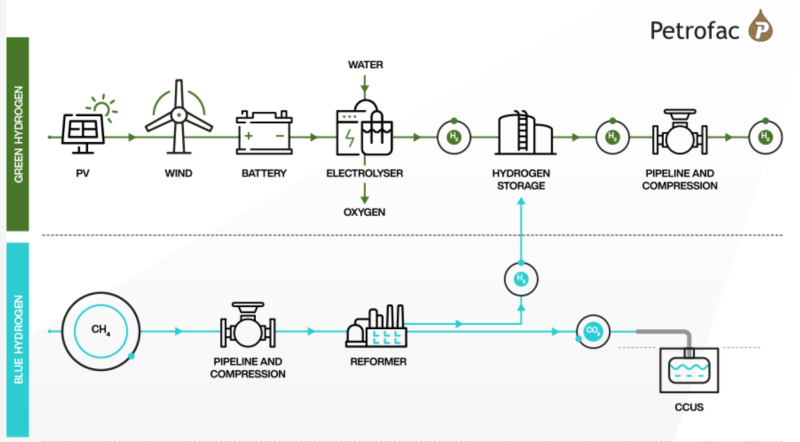

It is no longer breaking news that hydrogen is becoming a focal point of the decarbonization strategy in the oil and gas industry. Specifically, hydrogen produced from renewables (green) and natural gas using carbon capture, utilization, and storage (blue) offer promising pathways to reduce carbon emissions.

The oil and gas industry is leveraging existing expertise in project delivery, subsurface storage, and pipeline networks to accelerate this transition and, most importantly, scale hydrogen solutions.

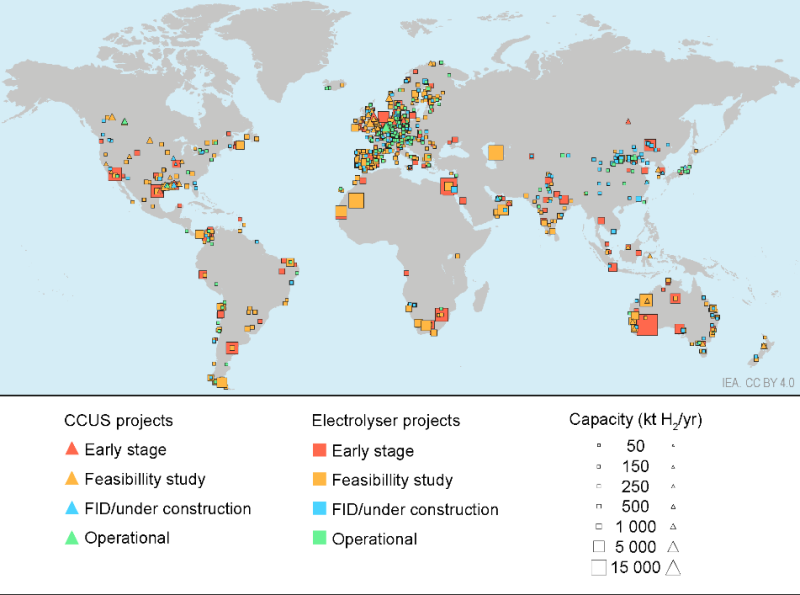

An overview of global low-emission hydrogen projects is presented in Fig 1. Both blue hydrogen and green hydrogen are experiencing rapid growth. Hydrogen production totaled 97 Mt in 2023, with low-emissions sources making up less than 1%. Announced projects suggest this could rise to 49 Mt per year by 2030, an increase from the 38 Mt projected in the IEA 2023 Global Hydrogen Review. Most projects currently under construction or in operation are concentrated in Europe, China, Australia, and the US.

Hydrogen Production: Blue vs. Green (Technical Comparison)

This section outlines the production processes for blue and green hydrogen, providing a technical comparison and detailing the advantages and disadvantages of each.

Blue Hydrogen (Natural Gas + CCUS)

Blue hydrogen is produced from natural gas using steam methane reforming (SMR) or auto-thermal reforming (ATR), with carbon capture and storage to reduce emissions. This process of producing hydrogen is currently less expensive than green hydrogen and leverages existing gas infrastructure but relies on high capture rates and still emits some carbon dioxide.

- Process: SMR or ATR with CCS.

- Pros: Lower cost today (blue at ~$1.50–3.50/kg vs. green at $3.00–6.00/kg) and utilizes existing natural gas infrastructure.

- Cons: Relies on natural gas, which carries the risk of methane leaks during extraction. Additionally, CCS technologies are not fully effective, allowing some emissions to remain.

- Case Study: Shell’s Quest CCS facility in Canada stores about 1 million tons of CO₂ per year as part of blue hydrogen production.

Green Hydrogen (Electrolysis + Renewables)

Hydrogen produced from renewable electricity is called green hydrogen. The process is made by splitting water using renewable electricity via proton exchange membrane (PEM), alkaline, solid oxide electrolyzer cell (SOEC) electrolyzers, resulting in zero emissions since the entire process is powered by renewables. Although this process is scalable and environmentally friendly, it is energy-intensive and is more expensive than other production methods for hydrogens.

- Process: Electrolysis using renewable electricity (PEM, alkaline, SOEC technologies).

- Pros: Zero emissions if powered by renewables and can decarbonize industrial sectors.

- Cons: Production is costly due to expensive renewable energy and electrolyzer technology, storage and distribution infrastructure is limited, and it requires large amounts of renewable power.

- Case Study: NEOM Green Hydrogen Project in Saudi Arabia aims to produce 1.2 million tons/year by 2026, powered entirely by solar and wind.

Integrating Hydrogen Into Existing Oil and Gas Infrastructure

Although there are many technical challenges with integrating hydrogen production, supply, and distribution into the existing oil and gas infrastructure, the following provide insights on the challenges and solutions.

Repurposing Pipelines and Storage

- Challenge: Steel pipelines are susceptible to hydrogen embrittlement.

- Solutions: Blending up to 20% hydrogen in existing gas grids, retrofitting with composite liners or new materials.

Offshore Hydrogen Production and Transport

- Opportunity: Combining offshore wind with electrolysis on oil/gas platforms to avoid grid constraints.

- Example: PosHYdon (Netherlands) is piloting offshore green hydrogen production using existing O&G infrastructure and transporting hydrogen via pipelines.

Subsurface Hydrogen Storage

- Options: Salt caverns (preferred), depleted reservoirs (with caution).

- Risks: Microbial activity, leakage, and material compatibility.

- Example: HyStock (Netherlands) is testing large-scale hydrogen storage in salt caverns, targeting 26 million kg capacity.

Economic and Policy Drivers

The industrywide challenges of hydrogen are cost-associated with its production and distribution. Therefore, for hydrogen to compete, the following needs to be achieved.

Cost Competitiveness:

- Blue hydrogen is considered economically viable if the costs of carbon capture and storage fall below approximately $50 per tonne of CO₂. This benchmark is cited in policy and technical analyses, including the 2020 Resources for the Future report on decarbonized hydrogen. However, there is need for incentives to make blue hydrogen economically competitive.

- Green hydrogen is still not broadly cost-competitive as blue hydrogen, with high capital expenditure and financing costs posing key barriers. That said, as renewable electricity and electrolyzer costs fall, and if carbon pricing strengthens, green hydrogen could close the gap—some projections see it reaching cost parity by 2030.

Global Policy Support:

- US: The Clean Hydrogen Production Tax Credit created a 10-year incentive for clean hydrogen of up to $3.00/kg.

- EU: The European Hydrogen Bank, launched in 2022, is a financing instrument run by the European Commission to provide investment security and business opportunities for renewable hydrogen production.

What This Means for Engineers (Career Takeaways)

Hydrogen integration presents not only business potential but also significant job opportunities, particularly in emerging roles. While hydrogen already plays a role in existing value chains, its growing importance in decarbonizing hard-to-abate sectors creates new demands for specialized skills and workforce development.

New Skills Needed:

- Electrolysis system design, CCUS integration, and hydrogen safety standards.

- Cross-disciplinary expertise in renewables and oil and gas systems.

Emerging Roles:

- Hydrogen project developers and commercial managers.

- Subsurface engineers for hydrogen storage projects.

- Pipeline integrity specialists focused on hydrogen transport and blending.

Conclusion

Hydrogen is no longer a futuristic idea—it is a present and expanding reality within the oil and gas sector’s transition toward low-carbon operations. Hydrogen, particularly in its blue and green forms, offers viable pathways to reduce emissions while leveraging existing oil and gas infrastructure, expertise, and investment capacity. Major industry players have already committed to ambitious net-zero targets, backed by hydrogen-centric strategies and large-scale projects across continents.

However, unlocking hydrogen’s full potential will depend on strategic integration efforts, such as repurposing pipelines, enhancing storage options, and improving the economics of production and distribution. Policy frameworks are already creating enabling environments, but further coordination between governments, industry, and academia is essential.

For engineers, this presents a pivotal moment to upskill, adapt, and lead. From electrolysis design and carbon capture to hydrogen blending and safety standards, the hydrogen economy will demand a new generation of cross-disciplinary professionals. As oil and gas companies evolve into broader energy firms, engineering talent will be central not just to building the hydrogen value chain, but to sustaining its growth for decades to come.