“Hydrogen is a colorless, odorless, and tasteless gas at room temperature and pressure.”

“Hydrogen is an energy carrier that can be used to store, move, and deliver energy produced from other sources.”

Modern civilization has been sustained by energy, predominantly powered by oil and gas for decades. About 70% of petroleum product is used for fuel. Recently, a strong candidate to replace them has emerged—hydrogen.

Hydrogen generates a clean and efficient energy alternative to traditional fossil fuels. Fuel cells convert hydrogen to energy and its only waste is pure water. Unlike battery electric vehicles, fuel cell electric vehicles carry the electricity generator and source. While the technology is still maturing, hydrogen’s potential as a fuel source is expected to surge in the coming years, catalyzing a shift in the global energy landscape.

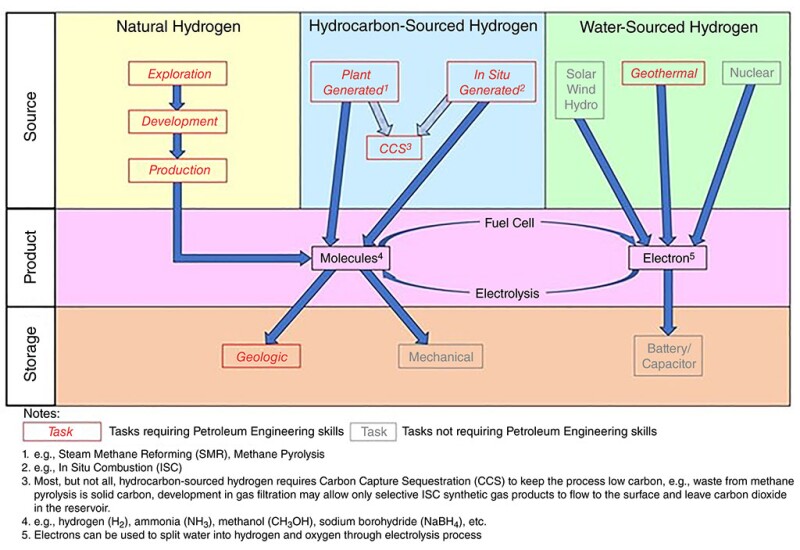

The transitioning from traditional fossil fuels, however, need not signal the end of petroleum engineering. With amassed experience and knowledge accumulated for more than a century, petroleum engineers can offer a massive contribution to the hydrogen industry. The hydrogen value chain, encompassing production, carbon capture and sequestration (CCS), storage, and distribution, can greatly benefit from this extensive source of skills and expertise.

Let us start with exploration. Hydrogen can be found in its naturally occurring reservoirs, which are garnering increased attention. Most of the opportunities are at the evaluation stage, but more exploration activities have been reported in the press.

Hydroma (formerly Petroma) made a first-of-its-kind discovery of a vast hydrogen reservoir in Mali, Africa, boasting a purity of 95% hydrogen with helium, methane, and nitrogen making up the other 5%. The reservoir pressure was reported to have remained stable for 4 years of production, indicating continuous in situ natural charging. These multiple reservoirs, which are at 100- to 500 m depths, were discovered while drilling a water well. With more exploration activities, our understanding of how to explore natural hydrogen reservoirs will be greatly enhanced.

Exploring and exploiting natural hydrogen reservoirs will require the application of petroleum geoscience and engineering knowledge. Geologists and geophysicists will lead the way. Then, the drilling engineers, reservoir engineers, production engineers, and facility engineers will play essential roles.

In regions without natural hydrogen reservoirs, hydrogen can be generated from water or hydrocarbon sources. Splitting water into hydrogen and oxygen can be accomplished through electrolysis (electricity), radiolysis (nuclear), and catalytic (high-temperature) processes. Petroleum engineering skills are not applicable to these methods of hydrogen generation.

Hydrogen generation from hydrocarbon sources, on the other hand, heavily relies on chemical and petroleum engineering skills. The steam methane reforming (SMR) process has long been employed for hydrogen production, which is commonly used to crack heavy oils into lighter oils in refineries. Refinery engineers are well-versed in the SMR process, where methane and steam generate hydrogen and carbon dioxide (CO2) as the final products. Capturing and sequestering the carbon dioxide byproduct is essential to keep this hydrogen generation process clean.

Petroleum engineers have the expertise needed for CCS. Engineers specialized in CO2 injection for enhanced oil recovery (EOR) possess knowledge and experience in injecting CO2 into reservoirs. Gas storage engineers and geologists know what kind of depleted reservoirs are good for storage and how to manage the reservoirs to minimize the possibility of leakage. By combining expertise from these disciplines, we have all the necessary skills for successful CCS implementation.

The methane pyrolysis process, which yields hydrogen and solid carbon black, does not require many petroleum engineering skills. However, it still relies on methane as its feedstock. Therefore, on minimum, facility engineers will be required in the plant. In-situ combustion (ISC), another EOR technique that can be optimized to generate hydrogen, requires the full range of expertise offered by petroleum engineering and petroleum geology. It is well known that ISC, an established oil extraction technology, produces hydrogen as a byproduct. BP conducted field pilot testing in the 1980s in Alberta, Canada, and has demonstrated the generation of synthetic gas with 20% hydrogen content by injecting pure oxygen into a heavy-oil reservoir. By focusing on hydrogen generation, studies suggested that optimization could achieve 40% or higher hydrogen content in the generated gas.

Once hydrogen is extracted from a reservoir or generated from water or hydrocarbon sources, it must be transported to storage and distributed to consumers. Flowing hydrogen requires specialized compressors and pipeline due to its unique properties and the risk of hydrogen embrittlement on steel. Facilities engineers, aided with this knowledge, can ensure the safe movement of hydrogen through pipelines, similar to natural gas pipelines.

Hydrogen storage methods parallel those used for natural gas. Manmade hydrogen storage requires specialized materials, while geological storage of hydrogen resembles natural gas storage techniques employed in the gas storage industry. Hydrogen can be stored in depleted natural gas reservoirs and salt domes. And, based on recent studies, saline aquifers also demonstrate promising potential for hydrogen storage.

While the complexities of the hydrogen industry may go beyond the simplicity of this article, they are not overwhelmingly complicated either. As a reservoir engineer currently working on designing and optimizing hydrogen generation through in-situ combustion, I understand that additional knowledge is required (Fig. 1). Building reservoir simulation models still involves factors like pressures, temperatures, viscosities, permeabilities, and porosities. In addition, chemical reactions have become a crucial aspect to account for. Though not simple, navigating these challenges is certainly achievable.

The transition to the net-zero emission era and the adoption of hydrogen as an energy source does not signify the end of petroleum engineering. The vast intellectual capital and expertise accumulated in this field can be seamlessly transferred to the hydrogen realm. The skills of drilling engineers, reservoir engineers, production engineers, exploitation engineers, facilities engineers, pipeline engineers, and the contributions from geology and geophysics remain relevant.

Hydrogen presents an opportunity for petroleum engineers to adapt and progress (Fig. 2). While oil and gas will continue to be produced for their numerous beneficial uses, in the future, they will no longer be burned as an energy source. The role of petroleum engineers is evolving. We must be agile and willing to embrace new opportunities. The name and titles of petroleum engineering may change, but the skills will be rooted from the same pool.

The Society of Petroleum Engineers (SPE) has always been at the forefront of oil and gas technologies. Recognizing the significance of hydrogen, SPE officially established a new technical section dedicated to hydrogen within the Projects, Facilities, and Construction discipline in November 2022. This addition reflects the recognition that hydrogen is a distinct realm while also having connections to existing disciplines.

The SPE Hydrogen Technical Section (SPE H2TS) is intended as a platform for industry and academic leaders to share their expertise and interest, exchange knowledge, and foster discussions. By joining SPE H2TS, individuals can engage with experts in their respective fields, contribute their own expertise, explore the fascinating world of hydrogen, and participate in discussions encompassing all aspects of hydrogen.

SPE is committed to continuous growth and nurturing future leaders who will guide the industry into the net-zero emission era.

In summary:

• Hydrogen is an interesting component of the energy industry's strategy to get to net-zero greenhouse gas emissions

• It is an additional option for

- Cleaner baseload electricity generation, like hydroelectricity, geothermal, and nuclear power generation.

- Direct usage as an alternative to electricity in heavy transportation and shipping.

• Hydrogen natural gas blends offer an opportunity to reduce CO2 emissions during the transition period, while new infrastructure is being developed.

• There are various potential sources of hydrogen, many of which offer great opportunities for petroleum engineers and all of which offer exciting opportunities for those of us with experience working on the planning of major projects, facility and infrastructure design, and construction and operations.

I extend sincere gratitude and acknowledgement to two individuals who played pivotal roles in the creation of the SPE Hydrogen Technical Section (SPE H2TS). Bob Pearson who approached me, and also the other founding members, with the idea of establishing a technical section dedicated to hydrogen. Additionally, Chris Kalli, the first and current chair of SPE H2TS, has provided exceptional leadership, enabling the successful launch and journey of this initiative. I am deeply grateful for their invaluable contributions to this article.

To join SPE H2TS, visit the link here, sign in, check mark “Hydrogen,” and do not forget to save before exiting.