The rapid development of shale formations over the past decade has led the United States to become the world’s undisputed leader in natural gas production. This success, though, has come with increased scrutiny over the environmental impact of high-density drilling activities required to maintain unconventional gas production. One of the issues that industry and environmental experts are working to understand involves the risk of stray gas migration into groundwater sources, which a recent university study linked to cementing and casing failures.

In their paper, researchers from Ohio State University, Duke University, Stanford University, and several other academic institutions, said the industry can do more to prevent this type of problem, ensuring that future onshore development poses as little risk as possible to people who live near oil and natural gas fields. However, there is scientific debate on such findings and whether natural sources of methane found in water sources are far more common. The early research by various organizations hopes to provide answers to questions such as the best way to sample residential water wells, how to distinguish naturally occurring methane from stray production gas, and what can be done to prevent well failures that might contaminate water.

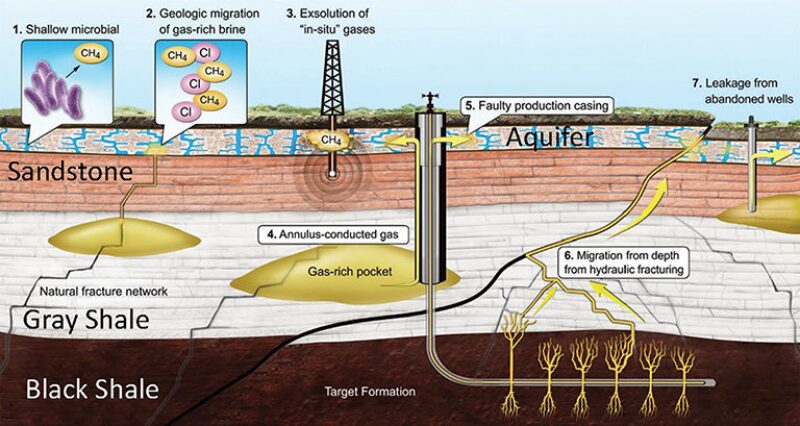

The Ohio State University-led study, produced by a team of Earth scientists, is one of the most comprehensive works on methane contamination to date and its findings were published in September by the Proceedings of the National Academy of Sciences, a 100-year-old, peer-reviewed scientific journal based in Washington, D.C. The study identified several potential ways methane can migrate into groundwater, and used noble gas analysis, which measures the isotopes of the gases that often accompany methane, to determine the most likely source.

Although it has been used for other scientific purposes for decades, previous research has not used this method to link methane contamination to gas well failures. The report read, “In general, our data suggest that where fugitive gas contamination occurs, well integrity problems are most likely associated with casing or cementing issues.”

The study involved taking samples from 113 water wells overlying the Marcellus Shale and 20 overlying the Barnett Shale during 2012 and 2013. One of its authors, Robert Jackson, a professor of Earth sciences at Stanford University, said higher-than-normal levels of methane were found in eight “clusters” of the sampled water wells, all located within 1 km of producing natural gas wells in Pennsylvania and Texas.

“In the minority of cases where we found contamination, some of them were alarmingly high—well above saturation,” Jackson said. “They bubble like champagne when you pull the water out of the ground.”

In the cases that were attributed to natural gas wells, Jackson said methane is either leaking out of the casing, or is coming from a shallower gas-bearing formation with insufficient cement isolation or an uncemented well section, thus allowing methane to flow up the annulus and into a shallow water-bearing layer.

Research efforts on methane migration related to unconventional wells are relatively young. For instance, Jackson, considered one of the world’s leading experts on the subject, has been studying methane migration into groundwater for only 5 years. Zachariah Hildenbrand, a scientist at Inform Environmental, began investigating groundwater contamination in 2011. He said that without establishing water quality baselines and increasing the number of tests, there will not be enough data available to know how common the problem is.

Hildenbrand said the goal of his research is to provide scientific evidence that will make it possible to develop practical solutions that work for oil and gas companies, regulators, and the people who live near well sites. Despite the “undeniable” economic benefits of shale gas development, Hildenbrand said the vacuum of reliable environmental information has contributed to public opposition of unconventional gas development. “In some areas where they have just banned fracking completely until they understand it, that might be a real mistake as opposed to just being cautious and taking the right experimental approach,” he said.

More Research Needed

At this time, it remains unknown to the industry and reseachers how often casing or cement integrity failures occur. George King, a distinguished engineering advisor at Apache, said he believes the proportion of wells leaking due to these factors is low. He explained the industry has shown its capability to prevent leaks through best practices; however, companies need to place more emphasis on the issue. “There is not a more critical need right now than there is to get a good cement job,” King said. “But this has not changed in 100 years. The most important part of a well is getting the isolation necessary to protect your reserves to protect the surface, and to protect the fresh water.”

Ann Smith, vice president of GSI Environmental, a Houston-based firm contracted by the US Department of Energy’s Research Partnership to Secure Energy for America (RPSEA) to study stray methane gas, said oil and gas companies and state regulators want to know how to confirm whether a stray gas incident has occurred and how to address incidents through reliable testing. Although she believes that methane contamination of groundwater is rare, the past couple of years of research has convinced Smith that “the bottom line about stray gas impacts is that they do occur.” The question, she said, is how to distinguish them from naturally elevated methane levels that can vary in intensity over time. Smith said the work that her firm is undertaking will help people learn more about how changes in methane concentrations occur and how to differentiate between changes as a result of oil and gas activity and natural causes. GSI is also analyzing the results from the Ohio State University study and will make its opinion available to the industry to further the discussion.

Casing vs. Cement

The findings of the study said the process of hydraulic fracturing is not directly linked to contamination of water wells. Based on the data collected, the university researchers said that there is no evidence to suggest that “horizontal drilling or hydraulic fracturing has provided a conduit to connect deep Marcellus or Barnett formations directly to surface aquifers.”

What the study does suggest is that the potential for problems exists when cement or casing failures occur. The study found four suspected casing failures and four suspected cement failures. Because the steel casing strings going down horizontal wells are relatively new and have not had time to corrode, Jackson said cement failures are probably more common than casing breaches. The reasons why the cement could be the cause of methane leaks range from drillers who do not use enough cement to seal off intermediate-layer gas from moving up the annulus to poor bonding between the production casing and the cement that leaves open small channels for methane to flow through.

This can be the result of irregular-shaped boreholes and centralizers that do not keep the casing in the middle of the borehole, said Kent Perry, vice president of onshore programs at RPSEA. As fluids and cement are pumped down the openhole annulus, they will always take the path of least resistance, he said. The cement “may flow alongside one side of the pipe, and not necessarily cover the entire circular portion of a hole, especially through the entire length,” Perry said. “That has been a well-known problem and a common problem.”

Mike Cowan, a senior research fellow at the University of Texas at Austin with 38 years of industry experience in well construction and cementing, said that methane can become fugitive gas through an opening as small as 0.0003 in. wide. “And a typical microannulus is on the order of .005 in. to .01 in.,” he said. If gas were to leak through a pathway this small, it could become a problem because once it reaches a section of uncemented borehole, it will flow freely at an even faster rate, Cowan explained. Compounding the rate of flow is the “pulling effect.” As gas expands through an opening, it is drawn up by the lower pressure.

Jackson said that if known gas-bearing sedimentary layers are left uncemented, natural gas may travel up the annulus like a “chimney.” This can happen when operators elect to leave thousands of feet of a well uncemented, which is allowed by state regulations in Texas if the operator determines that an intermediate gas-bearing stratum does not produce “commercial quantities” of hydrocarbons. Jackson cited the example of two gas wells drilled in 2009 in Parker County, Texas, and operated by Range Resources. Public records showed that the wells were completed with an uncemented section that extended downhole from approximately 400 ft to more than 4,500 ft.

Because a shallow gas layer known as the Strawn sandstone, which has produced natural gas in the area for decades, lies between these intervals, Jackson questioned the wisdom of not using cement to isolate such long sections of the wells. “If the gas is free to move up to 400 ft, now all of a sudden, it is not so difficult for me to envision cases where that gas could find some natural cracks and move up to 100 ft,” where an aquifer could be located, he said.

Some companies go beyond the minimum standards set by regulators and will cement sections that are hundreds of feet below and above the layers of concern. This effectively reduces the margin of error and the risk of gases seeping out of the annulus. Jackson said more companies should proactively adopt this type of practice. “If we could get the best practices from the best companies applied across the board, I think we could be in strong shape,” he said. “What we really want is for the other companies to be brought up to those standards in a way that does not require the (US Environmental Protection Agency) stepping in and telling them what to do.”

Effects of Hydraulic Fracturing

One of the questions raised by researchers studying the issue of stray gas migration is whether hydraulic fracturing introduces well integrity problems that lead to methane leaks. Kent Perry, vice president of onshore programs at RPSEA, said that the industry needs to dig harder to find the answer. “It really has not been looked into at the depth and degree that it probably needs to be,” he said.

Most oil and gas companies use modern technology and apply best practices for cementing and casing operations, Perry said. This requires the use of centralizers and other best practice techniques to ensure a competent cement job that will seal the wellbore from unwanted fluid entry or migration. By following the industry’s best standards, well integrity should be attained, Perry said. “In most cases, that is true,” he added.

Despite the use of centralizers and state-of-the-art technology, Perry said there have been instances of sustained casing pressure detected inside wellbores, which is most likely a sign of gas migration downhole or naturally occurring shallow gas finding its way into the wellbore. Perry said his experience in the industry leads him to believe that most leaks are a result of a poor bond between the cement and the casing.

When hydraulic fracturing takes place, large volumes of water are injected down the steel casing under high pressure, causing changes in temperature and pressure, and inducing mechanical stresses on the casing that he said may affect cement integrity. Perry said it is also important to take into consideration that while hydraulic fracturing has been carried out in wells for decades, they were usually single treatments; the multiple stage completions happening today involve dozens of treatments. That means that the increase in pressure, decrease in pressure, and temperature changes occur over many consecutive cycles before a long horizontal well is completed. “Exactly what that does to the cement is somewhat of an open question” and further studies to provide answers are warranted considering the importance of the issue, he said. He also explained that if there are “flaws” in the cement to casing< bond, these mechanical stresses, repeatedly introduced, could create a pathway for gas movement.

Natural Sources of Contamination

The issue of drilling- and production-related methane contamination is new largely because the nature of shale development requires many more wells to be drilled in proximity than ever before, and they are being drilled into deeper formations, which may expose more gas-bearing rocks to the wellbore. A colorless, odorless, and nontoxic gas, methane poses a relatively low health risk to people; however, it is highly flammable and its accumulation in residential water wells or homes is a safety concern. Owners of water wells in different parts of the US have been dealing with this problem as a result of natural causes for more than a century, some more than others.

Jackson said a well water study in which he was involved in the Fayetteville shale area in Arkansas turned up no signs of methane contamination, compared with the studies of the Marcellus and Barnett shales that did. It led Jackson to believe that “there are geological reasons for difference in stray gas flow, and I think there are human factors,” as well.

After spending years studying the different issues for the oil and gas industry and authoring 69 technical papers, many of which address risks associated with unconventional oil and gas development, King said he does not discount the possibility that some of the gas found in freshwater sources is a result of leaking casing or cement. However, he said that of the leaky wells he has seen in his career, only a small amount of fugitive methane was detected, perhaps a liter or two a day.

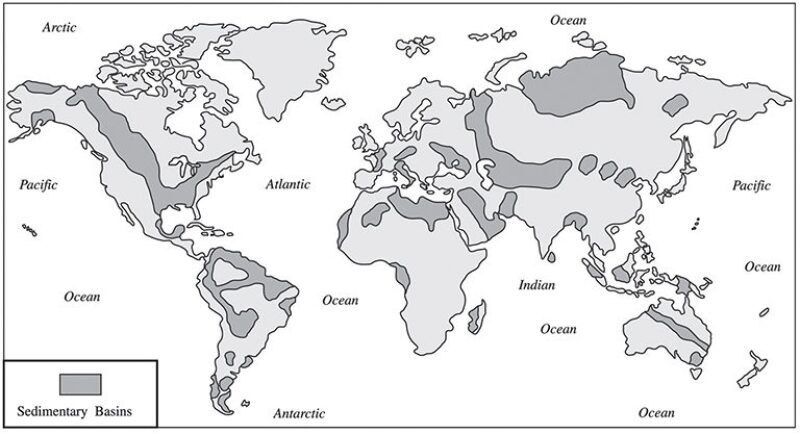

What he sees as a greater source of methane migration into groundwater has to do with the origins of the industry itself. In the 1800s, natural oil and gas seeps found in northeast US served as the first prospecting tool for the founders of the oil and gas industry. “Seeps and wells go hand in hand,” King said. “When you look at them, you can trace the outline of virtually every major field in the world.” A global estimate shows more than 10,000 active onshore seeps in the 112 countries that produce hydrocarbons.

In the US and Canada, there have been approximately 4.3 million production and injection wells drilled and, if placed in this context, King said the problem of methane contamination is less likely a result of oil and gas activity than some might think. “The issue here is that any patch of soil in the United States is going to involve some type of methane release,” he said. “Where it comes from is a significant question.”

Supporting this viewpoint is a report from the United States Geological Survey which found that 40% of water wells in New York, a state that passed a 3-year moratorium on hydraulic fracturing, have detectable levels of methane in the water even though no drilling activity has taken place. But in cases that involve “continuous feeds of methane, where none existed before,” King said, “you can pretty well assure that can be from a poor cement job, or something else that well has done to disturb the area around it.”

The National Ground Water Association, a US organization that tracks residential wells, reported that 15.9 million water wells have been drilled in the country. These wells were drilled with much less scrutiny than oil and gas wells and researchers have had trouble finding details on well construction plans to help determine how gas enters the wellstream. Smith said that many water well owners “do not know how deep it is, they do not know how it was installed, or if there was any kind of casing,” used.

Noble Gas Analysis

In the study led by Ohio State, researchers said it was the first time that a noble gas analysis was used to tell the difference between gas that comes from shallow formations and gas found in deeper source rock, such as the Marcellus and Barnett shales.

With this method, the study found four clusters of contaminated water wells in Pennsylvania with “Marcellus-like” gas in it. As Jackson explained, “The gas that comes out of a casing leak ought to look exactly like the production gas.” Of the cases where researchers claimed the contamination was probably the result of a nearby natural gas well that had suffered a documented “underground mechanical well failure,” the study said. Four additional wells, three in the Marcellus and one in the Barnett, were matched with gas from a shallower formation, with the result suggesting that poor cementing in an upper well section was the cause.

To determine whether the methane came from shallow pockets in the subsurface, from which gas could migrate upward naturally, or from the gas trapped thousands of feet underground that drillers are targeting, Jackson said noble gas analysis technology must be used. Methane and some noble gases, such as helium and neon, have different solubilities in water and diffuse at different rates, so researchers use the isotopic ratio to determine with confidence that the contaminated methane seeped from deeper formations and escaped upward through an unsealed section in the wellbore. “You expect (isotopes) to look quite different if they migrated (thousands of feet up) through the rock, than if they leaked out of a casing crack” and into an aquifer, Jackson said.

Cementing Concerns

Cowan, a zonal isolation expert, said while he believes that most wells drilled today do not leak, it takes only a small number of leaking wells in a field to introduce problems. He attributed the rising number of documented methane contamination in water wells in part to the lower-cost wells that use less casing and cement that would otherwise provide more barriers to fugitive gases.

“With cementing, you really have one shot to get it right,” he said. “And if you do not get it right, it is nearly impossible to fix.” The problem is hard to remediate, Cowan said, because the first step is to find the leak. He said current methods of well integrity testing are incapable of detecting tiny leaks and methane, being one of the smallest and lightest molecules on Earth, flows easily through channels too small for water or oil molecules to pass through.

One way for operators to check suspected leaky wells is by releasing the annulus pressure from inside the wells. If the pressure returns to the same level within a couple of days, then a leak is very likely, Cowan said. This is called sustained casing pressure. “If you take a back-of-the-envelope calculation and you know what the pressure is, how much volume it takes to bleed it off, you can get a rough idea of what is going on behind the casing and you can say if there is a lot more gas moving around here than was originally thought,” he said.

If a leak is present, companies use diagnostic technology, such as a cement bond log, to find the top of the cement level. Then a more sophisticated ultrasonic bond log tool is run into the well to map out channels and cracks; however, they are not always detectable, Cowan said. Part of the problem is that cement does not chemically or physically bond with steel. The cement is pumped in at a pressure that squeezes it against the steel as it hardens in place. “That is really what maintains the barrier,” Cowan said. “And if you lose that sealing stress, then the interface can be permeable.”

Paying Attention

Cowan proposed a solution for maintaining the sealing stress by using two casing strings downhole and placing the cement in between, thus forming a double barrier between the hydrocarbons being produced and the formation. Other improvements are probably needed, he said, including using electronic monitoring and data recording technology, so that companies can do a forensic analysis of suspect wells. “That data ought to be in the records, so that if anybody wanted to go back and focus on what wells are leaking, they will have information that will be pertinent,” he said.

With current cementing technology, Cowan said there can be no such thing as perfection. But in terms of what can be done to lower the probability of leaks, he said the industry needs to raise the standards in zonal isolation for sealing off exposure to the formation as much as possible. “If you get 99% zonal isolation in most wells, the problem will take generations to show up,” he said. “But what we are seeing is wells that have much less than 99%. It is 90%, 85%, or 80% and some are much worse than that.”

He suggested using wellbore strengthening additives to alter the permeability of exposed rock, thus making it impermeable and preventing gas from migrating out of and back into rock formations. “Then, the cement is just there for structure and as a secondary barrier,” Cowan said. “That is not the way we do things, but it could be done.”

Dedicating more personnel to oversee the cementing task is another solution. In years past, it was not uncommon for operators to routinely use specialists known as cement engineers as part of the drilling and completions team. Today, Cowan estimated that cementing expertise on a global scale is at a 30- or 40-year low. “The experts that we have lost are not being replaced with experts who have the same quality or depth of experience,” he said.

Years ago, when he was working for Amoco, King said that on the company’s most important wells, cement specialists would take over the project after the drilling and casing jobs. And when they were finished with a well, there were no further problems. “So, I do know that a lot of attention paid to a problem will cure the problem,” he said.

What changed over time were the implementation of stricter cost controls and the recent adoption of accelerated unconventional drilling programs that have led some companies to “run through the cement job very, very quickly,” he said. “A good driller can do a good cement job, but not if they are trying to break a record for how many days it took to complete the well.”

Now that the industry has mastered the practice of accelerated drilling schedules, it is time to turn its attention to ensuring quality cement jobs, King said. “Best practices change with time, and sometimes pretty quickly. So do not let best practices get in the way of better practices,” he said.

Establishing New Baseline Sampling Protocols

In the US, 16 out of 50 states have proposed or established rules or guidance for baseline sampling of residential water wells and other water sources near unconventional oil and gas production wells. Stephen Richardson, an environmental engineer at GSI Environmental, has reviewed the regulatory language from each of these states. He said they range from “very broad descriptions to very detailed descriptions” of how the baseline sampling should be carried out. This has created uncertainty and confusion for those tasked with designing and evaluating pre- and post-drill sampling programs in areas of shale gas development.

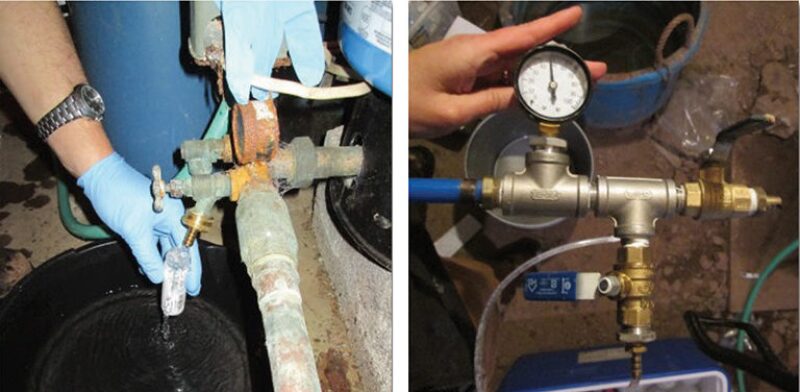

In response to the need for consistent guidelines, GSI was selected by the US Department of Energy’s National Energy Technology Laboratory and the Research Partnership to Secure Energy for America (RPSEA) to carry out a 3-year study that will produce a new set of protocols for predrill and post-drill testing of residential water wells near oil and gas wellsites. “What we noticed is that [the guidelines] are entirely different” from state to state, Richardson said. “There needs to be either regional guidelines, or more consistency,” so that operators that carry out predrill and post-drill sampling understand the effect of different sampling methodologies and select the most appropriate testing protocol. Another part of the GSI study is to use the results from predrill sampling and identify key relationships to better understand what parameters are most associated with naturally occurring methane.

GSI collaborates with a steering committee that includes universities such as Texas A&M University, professionals from oil and gas companies, and service companies. Ann Smith, vice president of GSI, said oil and gas companies have taken an active role in assisting the research by providing feedback, data, and wellsites for testing. “There is a concern and there is interest in finding out the answers,” she said. “I think everyone agrees that we need something that is consistent and repeatable.”

Also on the advisory committee is the Ground Water Protection Council, a nonprofit consortium made up of state groundwater regulatory agencies. Some of the strongest feedback received so far has come from the participating state oil and gas regulators, including the Railroad Commission of Texas, the Pennsylvania Department of Environmental Protection, and the Ohio Department of Natural Resources. Smith said these agencies are “trying to figure out what to regulate, how to regulate it, and what they should be doing.”

Although oil and gas companies are looking to rule out false positives, they do not want false negatives that show the methane level in samples from residential water wells are at lower concentrations than what is actually in the well. The most common cause of the problem comes from inadequate testing methods that allow the volatile gas to escape from sample vessels, Smith and Richardson said.

With low methane concentrations, where the gas is not so saturated that it bubbles up, common sampling methods such as direct fill using 40-ml vials work just fine. However, Richardson said this method has reliability problems when methane concentrations are higher because of the tendency of the gas to volatize and vent. What GSI believes is the best method for reliable water well sampling is a closed system that captures the water without allowing dissolved gas to escape during sampling. The product used in the study was the IsoFlask, a sampling device developed by Isotech Laboratories.

The research that GSI is undertaking should also help make use of the reams of water data collected by operators, said Smith. “What we are finding is that oil and gas companies have now collected a ton of predrill data,” she said. “But they are not entirely sure what to do with this data” to understand natural trends, let alone determine whether stray gas contamination has occurred.

Studying Heavy Metals

In a study published last year, researchers from the University of Texas at Arlington (UTA) discovered high concentrations of heavy metals inside water wells located close to hydraulic fracturing activity. The metals, arsenic, barium, selenium, and strontium, are naturally occurring groundwater ions, but can be dangerous when consumed at high levels.

“All of these (heavy metals) are free floating in the aquifer at very low levels,” said Zachariah Hildenbrand, one of the lead researchers in the study. “But what can happen is they can concentrate into iron oxide rust or scale formations at the base of people’s water wells.”

The research team’s theory is that the naturally occurring deposits of these heavy metals were somehow disrupted by nearby drilling and hydraulic stimulation activity, allowing them to transfer into the groundwater of private water wells. “To some people, that seems like a far reach,” Hildenbrand said. But he explained that for the enhanced levels to be absorbed into the water naturally, it would likely occur with a simultaneous increase in pH, a measure of acidity and alkalinity of a solution. When looking back through 15 years of water tests carried out by others, the UTA researchers found that pH levels in the area’s water supply had increased.

The most concentrated sample showed the level of arsenic to be 16 times higher than the level deemed safe for consumption by the US Environmental Protection Agency. Other samples showed levels of 5 to 8 times higher than the safe limit. These high readings were found only in water wells located 1 km from a gas well. Hildenbrand said that the findings support the theory that heavy metals inside the water wells may have been “liberated” by induced vibrations. However, he stressed that if this is the case, then “this is a very, very indirect mechanism by which hydraulic fracturing or unconventional drilling could be impacting groundwater.”

The study included 100 privately owned water wells from the Barnett Shale area in north Texas, and control samples that were taken from water wells located outside of the producing area. Besides heavy metals, the samples were all tested for chemicals used in hydraulic fracturing and volatile organic compounds that can show up with produced water. All samples tested negative for chemical compounds, suggesting that in the Barnett Shale, there is no evidence of a conduit for hydraulically induced fractures to introduce contaminants to groundwater aquifers.

Sampling and Water Testing Efforts Continue

Based on the feedback he received after the findings were published, Hildenbrand said the most important consensus reached was that a historical baseline was needed to make direct comparisons of the water before drilling and after drilling. This would offer more conclusive evidence that drilling and completion activity has had an effect on water quality. However, with the Barnett Shale being the birthplace of the shale revolution and home to more than 17,000 wells drilled in the past decade, establishing such a baseline in that area was impossible, he said.

But next year, Hildenbrand said his follow-up research has established such a baseline. The unpublished study, a collaboration between his company, Inform Environmental, and UTA, covered a 2-year time-series analysis of groundwater quality in the Cline shale located in the Permian Basin of west Texas. In this study, a set of measurements was collected at the onset of unconventional drilling in the area, with multiple iterations of samples being collected in conjunction with increased drilling activity. Additionally, Inform Environmental and UTA are finishing up an analysis of 550 private and public water supply wells in the Barnett Shale, the result of which should be available early next year. The team will also be reporting its findings from an analysis of groundwater quality in the Eagle Ford region.