Oil production from shale and tight formations accounted for more than half of total US oil production in 2015 (EIA, 2016). Such amount is expected to grow significantly as the active development of low-permeability reservoirs continues. The current technique to produce shale oil is through primary depletion using horizontal wells with multiple transverse fractures.

The oil recovery in shale oil reservoirs is less than 10% (Sheng, 2015a), or 3–6%, according to the EIA 2013 report (US DOE, 2013). The oil recovery in tight formations is also low. The gas recovery is 15–25% (Kuuskraa, 2013). A large percentage of the oil remains unrecovered without enhanced oil recovery (EOR) methods. In other words, there is a big prize to be claimed in terms of enhanced shale and tight oil recovery.

In this article, the technologies to enhance oil recovery from shale and tight formations are briefly summarized. Before that, some terminologies are clarified.

Terminologies Related to Shale and Tight Reservoirs

We have heard these terms:

Shale formation

Tight formation

Oil shale

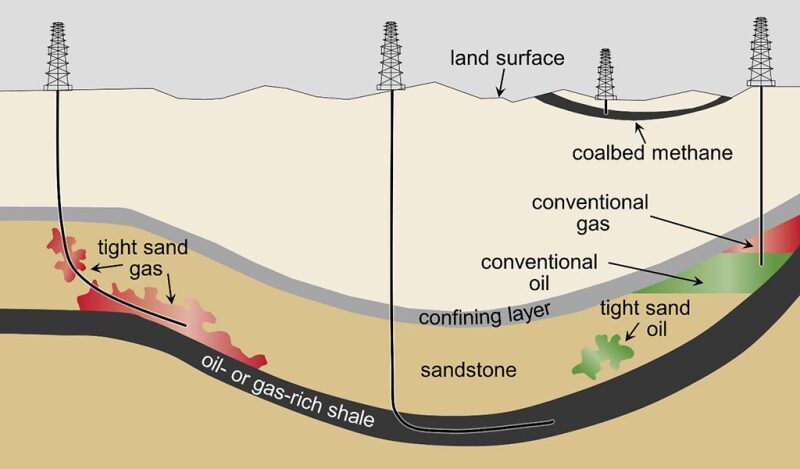

Shale is a laminated or fissile claystone or siltstone. The grain particle sizes are very small (< 1/256 mm in diameter (Pettijohn, 1957). A tight formation is a sandstone. One common and important characteristic about shale and tight formations is the very low permeability. Tight formation oil permeability is less than 0.1 mD (air permeability is less than 1 mD) (Jia et al., 2012); and matrix shale formation permeability is in the order of nano-Darcies.

Shale formations generally have small natural fractures, which can make the effective permeability higher than the order of nano-Darcies. Some authors in China classified shale formations as the rocks where hydrocarbons were generated in situ (source rocks) or migrated within a very short distance (Yang et al., 2015), and tight formations as the formations near source rocks (oil migrated in a short-distance) (Jia et al., 2014) or source-sand interbedded reservoirs (Zheng et al., 2017).

Actually, shale formations do not have to be source rocks. Strictly speaking, shale oil comes from shale formations like source rocks and mud shale rocks; tight oil comes from low-permeability sandstones, silty sands, and carbonates. In practice there seems no clear or agreed difference between these two terms, and they are used synonymously. Apparently, the term tight formation is commonly used in China, while the term shale formation is commonly used in the rest of the world, especially in the US.

There is a huge difference between oil shale and shale oil. Oil shale is a rock that contains a solid organic compound known as kerogen—a precursor to oil. Shale oil refers to hydrocarbons that are trapped in shale formations.

Injection Methods

A fluid, either water or gas, could be injected into reservoirs through a flooding mode or in a huff-n-puff (huff and puff) mode. For the flooding mode, a fluid is injected through a dedicated well and oil and gas are produced from a separate well or wells. For the huff-n-puff mode, after a fluid is injected through a well, in situ fluids (oil, gas and water) and a fraction of the injected fluid are produced from the same well. For the huff-n-puff mode, there is a time period the well is shut-in in some situations. This time period is called soaking time. The process of injecting-soaking-producing is repeated.

Produced fluids may be re-injected into reservoirs in some situations. Thus the fluids are re-cycled. Such cyclic injection can be performed in both flooding mode and huff-n-puff mode. However, in the petroleum literature, cyclic injection, more often, refers to huff-n-puff injection.

EOR Technologies

To understand the EOR potentials from gas injection and water injection in different modes, simulation results are summarized in Table 1 (Sheng, 2015b). From this table, these observations can be made.

Gas injection is better than water injection.

Gas huff-n-puff is much better than gas flooding.

EOR Potentials (Incremental Oil Recovery Factors) From Gas and Water Injection | |||

|---|---|---|---|

Gas Injection | Water Injection | ||

10 year primary | 5.75% | 10 year primary | 5.75% |

20 year flooding | 2.39% | 20 year flooding | 1.86% |

20 year huff-n-puff | 16.69% | 20 year huff-n-puff | 2.40% |

For gas flooding, gas may break through fractures from an injection well to production wells; or it is very difficult for gas to flow through matrix if the injection well and production wells are not connected through fractures. For huff-n-puff gas injection, there is no breakthrough issue, as the single well is used during the injection (huff) period and production (puff) period. Fractures provide a large contact area for gas to penetrate into matrix. The production increase can quickly respond to the injection. This comparison also applies to water injection.

Compared with water injection, gas has much higher injectivity and compressibility. Injectivity is very important, as shale and tight formations have very low permeability. Higher gas compressibility also makes gas an energized fluid to push oil out during the puff period.

The EOR potential of huff-n-puff gas injection has been confirmed by many experimental studies (e.g., Gamadi et al., 2013) and many simulation studies. The superiority of huff-n-puff gas injection to gas flooding has been confirmed by experimental studies for shale oil cores (Yu et al., 2017) and for shale condensate cores (Meng et al., 2017; Sharma and Sheng, 2017). And the superiority of huff-n-puff gas injection to huff-n-puff water injection has been confirmed by another experimental study (Yu and Sheng, 2017).

Both gas flooding and huff-n-puff gas injection were tried in field tests. It was surprising that gas can be injected without any injectivity issue for both of the gas-injection modes. However, significant oil rate increase was not observed in every field test. CO2 was used in all of the huff-n-puff gas-injection projects. For detailed field project performance, see Sheng (2017).

In US and Canadian shale formations, several waterflooding and water huff-n-puff projects were conducted. Consistent with the published laboratory research, field test results showed that water injection was less effective than gas injection. In China, large-scale water injection is carried out in tight formations whose permeability is in the order of micro-Darcies to milli-Darcies. The water injection increased oil production.

To enhance oil recovery, sometimes surfactants are added in fracturing fluids to change wettability and reduce oil/water interfacial tension. However, well performance could not distinguish the wells with surfactants injected from the wells without. Therefore, how surfactants play their role in enhancing oil recovery needs more fundamental research.

More methods have been tried in China, such as air foam drive, extending soaking time after fracturing, and microbial EOR (Sheng, 2017). Some research papers have been published on other EOR methods, such as air injection (Jia and Sheng, 2017), and thermal stimulation by high frequency electromagnetic (microwave) heating at the wellbore (Egboga et al., 2017).

Further Remarks

More than 90% of oil may remain in shale and tight formations. Because of ultra-low permeability, it is very challenging to make any EOR method work. Although an EOR technology may work and increase oil recovery, a high percentage of oil may still remain in the ground. Enhancing oil production from the shale and tight reservoirs will be a long-lasting challenge.

References

Egboga, N.U., Mohanty, K.K., and Balhoff, M.T. 2017. A feasibility study of thermal stimulation in unconventional shale reservoirs, Journal of Petroleum Science and Engineering, 154, 576–588.

Energy Information Administration (EIA). 2016. Annual Energy Outlook 2016 with Projections to 2040, DOE report DOE/EIA-0383.

Gamadi, T.D., Sheng, J.J., and Soliman, M.Y. 2013. An Experimental Study of Cyclic Gas Injection to Improve Shale Oil Recovery. Paper SPE 166334 presented at the SPE Annual Technical Conference and Exhibition held in New Orleans, Louisiana, USA, 30 September to 2 October.

Jia, H. and Sheng, J.J. 2017. Discussion of the feasibility of air injection for enhanced oil recovery in shale oil reservoirs, Petroleum, 3, 249–257.

Jia, C.-Z., Zheng, M., Zhang, Y. 2014. Four important theoretical issues of unconventional petroleum geology, Acta Petrolei Sinica, 35 (1): 1–10.

Jia, C.-Z., Zou, C.-N., and Li, J.-Z., Li, D.-H., and Zheng, M. 2012. Assessment criteria, main types, basic features, and resource prospects of the tight oil in China, Acta Petrolei Sinica, 33 (3): 343–350.

US DOE. 2013. EIA/ARI World Shale Gas and Shale Oil Resource Assessment, EIA report.

Meng, X., Sheng, J.J., and Yu, Y. 2017. Experimental and Numerical Study on Enhanced Condensate Recovery by Huff-n-Puff Gas Injection in Shale Gas Condensate Reservoirs, SPE Reservoir Evaluation & Engineering, May, 471–477, SPE 183645-PA.

Pettijohn, F.J. 1957. Sedimentary Rocks, 2nd ed., Harper & Row Publishers, New York.

Sharma, S. and Sheng, J.J. 2017. A comparative study of huff-n-puff gas and solvent injection in a shale gas condensate core, Journal of Natural Gas Science and Engineering, 38, 549–565.

Sheng, J.J. 2015a. Increase liquid oil production by huff-n-puff of produced gas in shale gas condensate reservoirs, Journal of Unconventional Oil and Gas Resources, 11, 19–26.

Sheng, J.J. 2015b. Enhanced oil recovery in shale reservoirs by gas injection, Journal of Natural Gas Science and Engineering, 22: 252–259.

Sheng, J.J. 2017. Critical Review of Field EOR Projects in Shale and Tight Reservoirs, Journal of Petroleum Science and Engineering, 159: 654–665.

Yang, W., Feng, Y., Yang, Y., Fu, X., and Feng, Y. 2015. Conditions of Shale Oil Accumulation and Distribution of Favorable Areas in China, Xinjiang Petroleum Geology, 36 (3): 253–257.

Yu, Y. and Sheng, J.J. 2017. A comparative experimental study of IOR potential in fractured shale reservoirs by cyclic water and nitrogen gas injection, Journal of Petroleum Science and Engineering, 149: 844–850.

Yu, Y., Li, L. and Sheng, J.J. 2017. A comparative experimental study of gas injection in shale plugs by flooding and huff-n-puff processes, Journal of Natural Gas Science and Engineering, 38: 195–202.

Zheng, T.-Y., Pang, X.-R., Zhang, K., and Zhou, L.-M. 2017. Determination of the lower properties of an effective reservoir for the tight West Slope of Mahu Sag, Science Technology and Engineering, 17(24): 196–203.

James Sheng is a professor in the petroleum department of Texas Tech University. He worked in the oil industry for more than 20 years before entering academia. He holds a PhD degree from the University of Alberta. He is the author or coauthor of more than 200 papers, and holds 5 US patents and 2 provisional US patents. He has published two books: Chemical Enhanced Oil Recovery, and EOR Field Case Studies. He received several professional awards including the SPE Regional Technical Award for Southwestern US twice, in 2013 and 2015; TTU Whitacre Engineering Excellent Research Award in 2015; Most Influential Faculty Member in 2015, the Fulbright Specialist Grant; and the Outstanding Associate Editor Award for SPE Reservoir Evaluation & Engineering journal in 2008.

The article was sourced from the author by TWA editors Ali Habibi, Avi Aggarwal, Renato Rios, Shubham Sharma, and Lavish Garg.