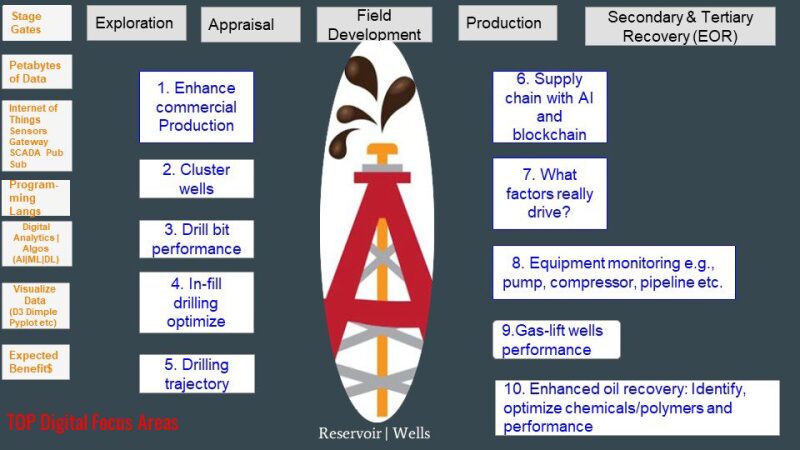

Digital oil and gas applications are expanding by leaps and bounds, providing insights and improving decision making and execution. Here are the top areas which could significantly improve business bottom line:

1. Exploration and production: For increasing/enhancing commercial production of hydrocarbon. Artificial intelligence (AI) methodologies could predict realistic values of reserve estimation and production forecasts augmenting the traditional Decline Curve Analysis. Real-time data from multiple sources could warn ahead of time of deviations in productions and trigger possible actions.

2. Group wells and their behavior: Identify group of wells with similar characters/behaviors using AI to understand the subsurface, production profiles, pressure, productivity index (PI), etc. in managing the wells based on historic and real-time data.

3. Drill bit performance: Monitor, identify, and predict bit performance in real time, which depends on a number of parameters such as rock strength, flow rate, porosity, and permeability and act ahead of time (proactive).

4. Well, facility, and reservoir management (WRFM): WRFM integrates multiple tools and subject matter experts from production, reservoir management, petrophysics, geology and much more. This is a fertile area for digital applications such as real-time data monitoring, exception-based surveillance (three sigma +/− techniques), daily performance review (24-hour performance variance/improvements), and reservoir pressure data. Machine learning/deep learning/tensor techniques could be straightaway applied here.

5. Manage non-hydrocarbon supply chain efficiently: An interesting and important area, procurement, materials management, and inventory is where millions and billions of dollars are spent in oil and gas business, which lacks transparency and have databases that lack quality and does not communicate across the supply chain of impending projects and production. Digital efforts could streamline and improve efficiency on the first phase to subject the digital supply chain for larger goals such as AI and blockchain applications.

6. Which factor really drives? Variable/feature ranking methods: Methods such as principal component analysis could help identify the importance of the order of parameters determining the production performance and help focus efforts on what really drives performance than fishing everywhere. This helps in reducing cost and time while improving production and profits.

7. AI in in-fill drilling: Determining the number of in-fill wells to be drilled and their location is often a challenge given the limitations of budget and the goal of getting the bang for the bug. AI could help in optimizing the number of in-fill wells to be drilled based on a range of constraints from technical, commercial, to financial.

8. AI in drilling trajectory/optimization: Well trajectory to be drilled to maximize production can be identified while minimizing cost and other technical considerations—a real-time digital solution based on sensors, Internet of Things, big data in real time, and AI algorithms to predict.

9. Equipment monitoring: This is one of the well known areas of AI and big data applications in areas such as pumps, compressors, and pipelines where historic data and real-time data help to predict unexpected shutdown events leading to non-productive time resulting in increased Opex and reduced profit. AI plays a significant role in predicting, proactively acting, and in some cases even preempting these threats.

10. AI in gas-lift wells: Pressure profiles, PI, and sensor data such as vibrations could help in predicting unpleasant events and take remedial actions on gas-lift adjustments.

11. Enhanced oil recovery (EOR): Which assets to invest in EOR and what EOR techniques to use? AI could significantly improve oil recovery from wells based on chemicals/polymers planned and compare with other well behavior under varied circumstances.

Chakravarthy Sampath Narayanan leads Arcishmaan Elements, a digital startup focusing on oil and gas business across the value chain and another in the production of bitumen pellets. He is an oil and gas professional with leadership experience in upstream and downstream business profitability, cost, and operational efficiency. He has more than 23 years of experience working across six countries in Asia, Middle East, and Europe with Shell, Mangalore Refinery and Petrochemicals, Oil and Natural Gas Corp., Abu Dhabi National Oil Company, and Kuwait National Petroleum Company. He worked in a broad range of roles in upstream business planning, portfolio, strategy, change management, supply chain, trading, refining operations, installation, and commissioning of projects for a grass root refinery. He is consulted by major oil companies in his previous and current roles. The author can be reached at Chaks@Arciselements.com.