The list of challenges facing artificial lift systems in horizontal shale wells is a long one, and the stakes are high.

From the shape of the borehole to harsh downhole conditions, horizontal wells are pushing the technology to its limits. The hurdles have become even higher for operators that have prioritized drilling wells as fast as possible, reducing completion costs, and attaining high initial production rates without considering the implications on long-term production.

Over the past decade, oil and gas companies have borrowed billions of dollars to drill more than 70,000 horizontal wells across North America, an estimated 95% of which are dependent on some type of artificial lift to keep flowing. The investment in many of these wells has been predicated on the idea that they will profitably produce for 20 to 40 years.

Whether that promise can be delivered will in large part “be pinned upon the reliability and the cost effectiveness, or the efficiency, of the artificial lift systems that we have,” said Kyel Hodenfield, president of artificial lift systems for North America at Schlumberger.

Hodenfield and a panel of three other industry experts made the case for why artificial lift should be at the forefront of a shale producer’s mind at the recent Unconventional Resources Technology Conference in San Antonio, Texas.

At the heart of the matter is the fact that unconventional wells are the most complex wells that artificial lift vendors have ever had to work with. “Our wells are not getting any simpler,” said Richard Luht, an executive technology leader at GE Global Research. “They are getting deeper, hotter, and (have) longer-reach laterals.”

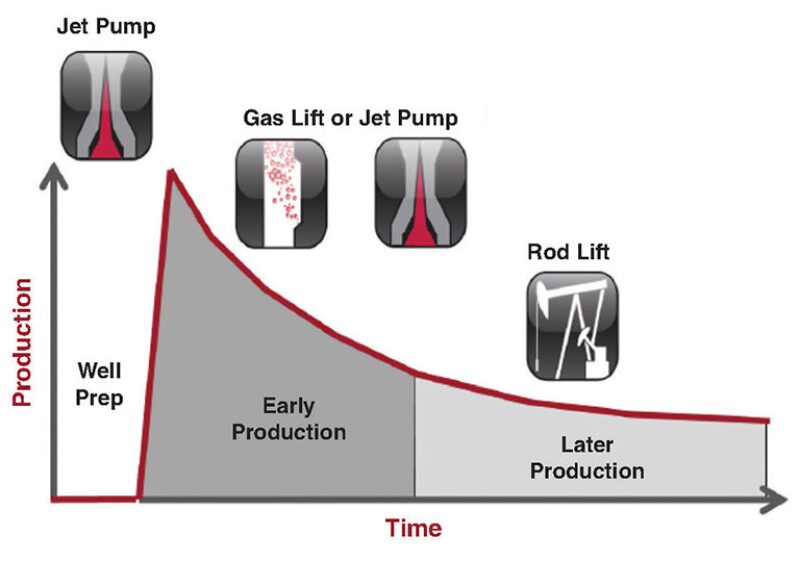

A defining characteristic of shale wells is their steep decline rates, which means some wells come onto pump within a matter of weeks of being completed. And in the first year of production, multiple artificial lift systems may be installed in a single well as the rapid change in water, oil, and gas production dictates which variation of the technology will work best.

Additionally, almost all unconventional wells produce corrosive fluids, paraffin, and asphaltenes. These issues arise much earlier in the life cycle of an unconventional well compared with a conventional well. They also leave behind thousands of pounds of proppant sand during the fracturing operation.

In the Bakken Shale in North Dakota, where this problem is particularly common, Hodenfield said new technology designed to pump sand to the surface has become so successful that it has presented a new problem of designing surface facilities to handle the large volumes. This is just one of several examples of the significant expenditures that operators must make to keep their aging assets flowing.

A shale producer whom Hodenfield has worked with expects the operating costs of its artificial lift program to rival the cost of drilling the wells. Luht added that a number of companies are concerned about electricity costs and what it will take to keep their lift systems in good shape to be as efficient as possible. “One operator was saying to me they are planning on spending tens of millions per year on electricity for artificial lift,” he said.

If operators adopt well designs and production strategies that lend themselves to artificial lift technology, then they may achieve the ultimate recoveries their investors are expecting. In the dimmest of scenarios, the problems outlined by the experts may force shale producers into the difficult situation of lowering their booked reserves as wells are taken off line because too many lift systems are failing or they become too expensive to operate.

Nonetheless, for some companies, the economic drivers of today supersede tomorrow’s production—and profits.

“Some may be very determined on accelerating production to fuel near- term cash flow” to fund future development, boost their stock price, or flip their assets to another producer, Hodenfield said. “Whereas other clients want to approach it much more from a return on investment and capital, looking at the long term (net present value).”

Well Communication

One of the keys to success will involve breaking through the current communication barriers that exist between the engineers who construct the wells and those tasked with ensuring they churn out oil and gas for decades to come, another expert said. Shauna Noonan, who is a completion technology manager at ConocoPhillips, has worked on artificial lift projects around the world and is a longtime advocate of the importance of artificial lift management.

“We’ve really seen in the unconventionals that the reservoir community and the drilling and completion community have come together very well because it is needed to understand the stimulated reservoir volume,” she said. However, “the production people are an afterthought.”

Noonan suggested that shale producers start planning their developments the same way that the majors prepare for large overseas developments and deepwater projects using integrated teams. When the drilling, completion, and reservoir teams are brought together with the production team and artificial lift vendors, the full impact of well design on production and equipment reliability is more likely to be scrutinized.

Alex Vilcinskas, a senior artificial lift advisor with Baker Hughes, said team collaboration is important because “the drilling department probably has a well for about 20 days and then it goes to production and they may have it for 20 years … of course, if we are lucky, it will be that long.”

The problems shale producers are encountering with artificial lift are not new. But change comes slow and it comes slower when there are few operators willing to move the needle. As Noonan explained, the competitiveness of the unconventional business means useful information on shale production is tight holed.

“It’s extremely difficult” to get companies to participate in forums and workshops on artificial lift, she said. Emphasizing her point, Noonan explained that she was speaking at the conference not on behalf of her company, but in her capacity as the SPE technical director for production and operations.

Other Downhole Dilemmas

Much of the lift equipment was designed to meet the needs of conventional wells, not wells with 10,000-ft vertical depths and lateral sections that extend for another mile or two. When drilling these long lateral stages, steel costs consume a large slice of the budget which is why many operators opt for casing and liners with internal diameters as narrow as 4 in. to 5½ in.

While using smaller casing saves money on the front end, “it is very hard to get anything in there,” said Vilcinskas. The difficulty of producing from narrow casings at extremely long lateral distances has been equated to sucking on a drinking straw the length of a football field.

Proposing something of a compromise, Vilcinskas said operators should consider using casings with larger internal diameters, perhaps 7 in. wide, to where the well first intersects the formation. At that point, a larger pump can be easily installed and the well continued forward with smaller liners and casings.

A key benefit of wider casings is that they alleviate the workload on the pumps by allowing more gas to flow freely to the surface. Narrow casings mean that longer and thinner pumps must be used to provide the necessary lifting power. However, this increases the difficulty of installing, maintaining, and running the pumps. “Even though we are coming up with ideas for smaller casing, most of those ideas still work a lot better in a bigger casing,” Vilcinskas said.

Well spacing is another example of where thoughtful decision making in the planning stage can make life much easier for a production team. When wells are drilled too close to each other on a pad site, and artificial lift systems are later installed, companies have discovered that there is no room for an intervention rig to come in and service the wells properly. In order to make space for the rig, they are forced to shut in production.

“It is somewhat short-sighted,” said Hodenfield, adding that some companies have learned their lesson. “What used to be maybe 20 ft is now going to 30 ft, or even 40 ft or 50 ft between.”

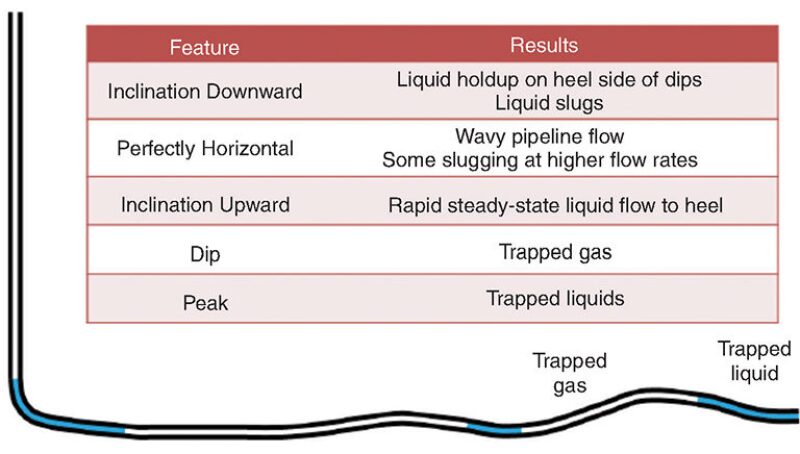

Another practice that would improve artificial lift performance involves drilling straighter wells. Unlike the perfectly level lateral sections illustrated in marketing materials, the reality is that most horizontal wells are defined by a series of small hills and valleys made as the driller surveys and corrects the wellbore trajectory.

Based on Schlumberger’s experience in simulating multiphase flow in offshore pipelines, Hodenfield said it is well proven that such deviations and undulations are bad news for flow. An uneven wellbore is likely to create eddies that slow the flow. Bumps and humps can trap fluids and gas, resulting in the formation of slugs. Once enough pressure has built up to push the slug along the wellbore, it can hit an artificial lift system hard enough to rattle the wellhead.

Rotary steerable systems are capable of drilling a rifle barrel borehole, which would eliminate most of the undulations and facilitate flow. The hard part is getting operators to realize the value proposition of that technology and the other added costs of planning for the future.

New Ideas and Technologies

While a paradigm shift in process management seems to be the ultimate solution, nearly every manufacturer of artificial lift equipment continues to develop new technologies. Vilcinskas said some are aiming to make simple yet important improvements to hydraulic systems and to optimize the speeds of the up-and-down strokes on rod pumps.

But more advanced research is also under way. For example, some are working to develop long-lasting carbon fiber rods that are stronger than steel, corrosive-resistant, and lighter than the rods used in pumps today. “Eventually, they may be the most common thing out there,” Vilcinskas said.

Schlumberger is investigating ways to harvest the energy of the reservoir. Hodenfield said this emerging area includes looking at everything from using temperature differences to burning the gas downhole to help lift systems move the liquids to the surface.

“Some of those are farfetched ideas,” he said. “But when you combine a couple of them together, I think there is something that may come.”

Other ideas remain far on the horizon. Among them is an idea for a pump that can be installed in the lateral section of the well to help draw down oil and gas from the toe, the section of the well that contributes little to no production. Hodenfield said the development of such a technology is not very feasible due to issues of reliability, serviceability, and cost.

Some of the new technologies expected to come into the fold will lean on proven systems. GE wants to incorporate condition-based monitoring technology into its artificial lift systems to give operators the opportunity to perform maintenance or interventions before a lift system fails, Luht said. The company has been using this type of technology in its aviation and electrical turbine businesses for some time and recently integrated it into its subsea blowout preventers.

Among the most prominent trends in technology uptake over the past few years has been the wave of permanent fiber-optic installations in shale fields across North America. One form of the technology, distributed acoustic sensing (DAS), is mostly used to measure completion and hydraulic fracturing design and performance.

If the fiber-optic cable survived the completion and stimulation treatments, Noonan said that operators could recycle the DAS system to detect early signs of failure such as rod buckling, physical contact with the tubing walls, or the “chattering” of moving pump parts. “With all this data, we don’t know what we may find,” she said. “We may learn a little or we may learn a lot, but I think the opportunity is there for us to learn something.”

For Further Reading

SPE 169833 An Integrated Lift-Time Artificial Lift Selection Approach for Tight/Shale Oil Production by N. Khan and L. Ganzer, Technical University of Clausthal; V. Elichev, Wintershall Holding GmbH; et al.

SPE 173974 Optimizing Completions and Artificial Lift in an Unconventional Play in the United States by S. Van Sickle and G. Shelly, Chaparral Energy; and D. Snyder, Packers Plus.

SPE 174053 Using Dynamic Simulations to Optimize the Start-Up of Horizontal Wells and Evaluate Plunger Lift Capability: Horn River Shale Gas Trajectory-Based Case Study by C.M. Nascimento and A. Becze, Schlumberger; C.J. Virues, Nexen; et al.

SPE 1921823 Considerations for Optimizing Artificial Lift in Unconventionals by W. Lane and R. Chokshi, Weatherford.