Artificial lift

To overcome operational constraints tied to ball-and-seat valves, an operator tested a spring-loaded alternative downhole.

Field results highlight how rethinking tubing-anchor-catcher design can reduce gas interference and support late-life production.

Experience in subsurface production and lift design is shaping a new generation of geothermal operations built for reliability and scalability.

-

Operators are turning to new gas-lift and nanoparticle-fluid technologies to drive up production rates.

-

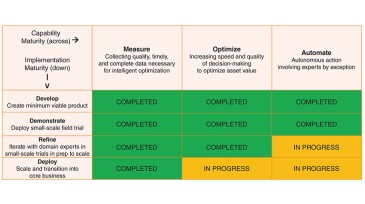

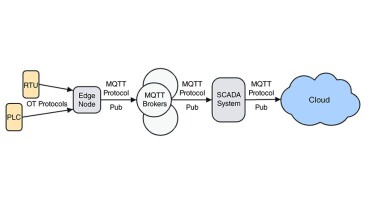

This paper presents a case study highlighting the demonstration, refinement, and implementation of a machine-learning algorithm to optimize multiple electrical-submersible-pump wells in the Permian Basin.

-

This paper presents a closed-loop iterative well-by-well gas lift optimization workflow deployed to more than 1,300 operator wells in the Permian Basin.

-

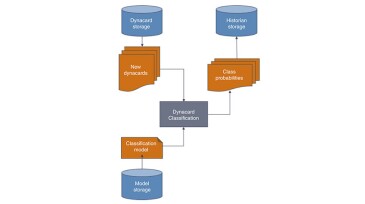

This paper explores the use of machine learning in predicting pump statuses, offering probabilistic assessments for each dynacard, automating real-time analysis, and facilitating early detection of pump damage.

-

The accelerating deployment of machine learning and automation is changing the artificial lift landscape. By embedding intelligence into the control loop, operators now can move from reactive decision-making to proactive, continuous optimization.

-

A 2D computational fluid dynamics model is extended to a 3D submodel and validated to provide detailed information on the state of the standing valve as a function of time to assist in sucker rod pump design and operation.

-

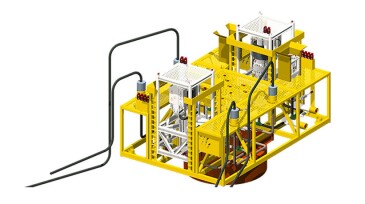

By closely monitoring its subsea boosting system, Shell extended maintenance intervals and safely postponed pump replacement at its ultradeepwater Stones field.

-

The use of real-time wireless downhole pressure gauges proved a valuable alternative to workover operations in two onshore fields in Iraq.

-

In the wake of the falling number of exploratory wells in the country, Brazil-owned Petrobras addressed audience concerns as well as outlined new avenues for production at the Offshore Technology Conference.

-

Three case studies consider the gas-related reasons electrical submersible pumps fail in unconventional shale environments.

Page 1 of 16