Drilling/completion fluids

Two critical facets of the discipline of well control and wellbore integrity—decarbonization and groundbreaking automation of essential processes—are highlighted in the three primary paper selections presented at SPE and SPE-affiliated conferences during the past year.

One major challenge for drilling-fluid engineers is the design and management of optimal drilling-fluid formulations in emerging frontiers—fractured formations and high-pressure geothermal environments. Recently, operators have leveraged cutting-edge technology such as machine learning and expanded data-driven techniques to facilitate the development of new drilling-f…

This research aims to develop a fluid-advisory system that provides recommendations for optimal amounts of chemical additives needed to maintain desired fluid properties in various drilling-fluid systems.

-

This paper describes development of a high-temperature water-based reservoir drill-in fluid using a novel synthetic polymer and customized with optimal chemical concentrations and sized calcium carbonate.

-

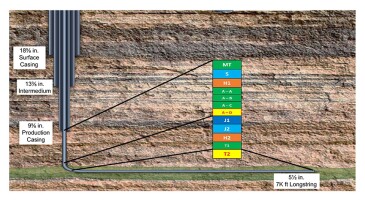

In this case study, a geomechanics-based approach was used to create bridging and sealing at the fracture aperture using a biparticle self-degradable lost-circulation-fluid system.

-

This paper describes an experimentation trial deploying and operating a computer-vision system on a deepwater rig to measure drilled cuttings in real time using a remotely monitored camera system.

-

Researchers with the National Energy Technology Laboratory showed that naturally occurring signals in underground fluids can serve as effective indicators of flow patterns between existing wellbores. Understanding these patterns can lead to increased efficiency and safety.

-

This paper highlights nontraditional methods to cure oil-based-mud losses in horizontal wells drilled in unconventional plays.

-

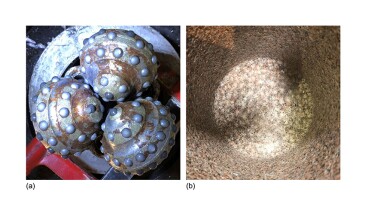

This paper evaluates the effect of rapid cooling on the rock-cutting process and incorporates this effect as a component of drilling-performance optimization.

-

Advancements in new technologies and rigorous testing methods have enabled the authors of the three SPE papers featured this year to outline a path forward, offering new possibilities that uphold the core objectives of safety and productivity.

-

This year’s primary selections for the Drilling and Completion Fluids Technology Focus reflect now-well-established industrywide emphases on machine learning, automation, and the achievement of successful drilling of CO₂ storage wells.

-

This paper highlights a new online system for monitoring drilling fluids, enabling intelligent control of drilling-fluid performance.

-

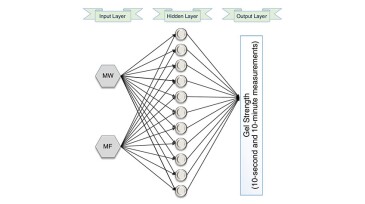

This paper investigates the use of machine-learning techniques to forecast drilling-fluid gel strength.

Page 1 of 10