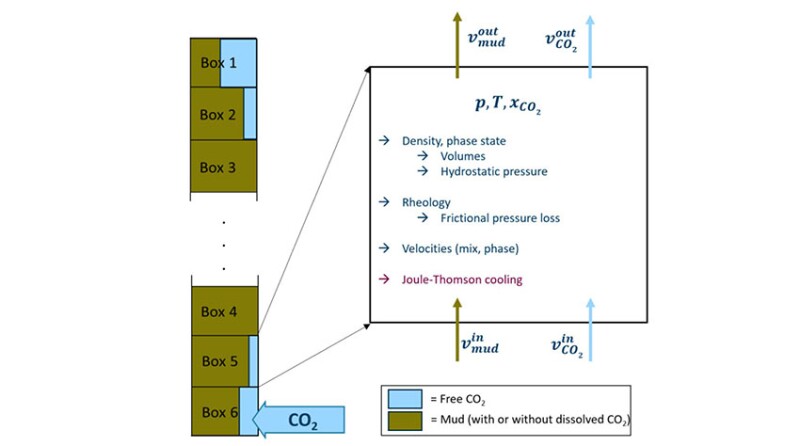

Drilling carbon-dioxide (CO2) storage wells is a task expected to involve handling an influx of CO2 into the drilling fluid. In the study described in the complete paper, experimental characterization of density, rheology, phase envelope, hydrate formation, and drilling-fluid stability are performed on drilling fluids mixed with CO2 for relevant pressures and temperatures. Based on these experiments and verified thermodynamic model descriptions, local models for properties of drilling-fluid/CO2 mixtures were developed and integrated into an existing drilling software suite.

Requirements for Enhanced Well-Control Software

Well-control-evaluation software based on sophisticated and verified models of the drilling-fluid/gas interaction in the wellbore plays an important role in planning drilling operations. The software also can be used to evaluate the strategy for circulating out a kick and regaining control of the well.