Inspection/maintenance

The Norwegian major said it is using artificial intelligence for predictive maintenance throughout its facilities and for interpretation of seismic data from the Norwegian continental shelf.

Sponsored

As HPHT wells push equipment to the edge of material limits, operators are turning to advanced thermoplastics and sealed electrical assemblies to maintain system integrity. From ESP insulation to BOP control systems, the right component design can prevent failures, lower intervention costs, and extend equipment life in the harshest offshore environments.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

This paper describes the development of a system for comprehensive mapping and asset registration using a digital-twin approach.

-

SponsoredAdvance your career with the new Pipeline Engineering Program at the Technical University of Leoben, a 5-month course combining on-campus and online learning, integrating industry expertise, engineering practice, and future-ready skills for professionals in oil, gas, and emerging energy systems.

-

In today’s era of asset management, digital twins are changing risk management, optimizing operations, and benefitting the bottom line.

-

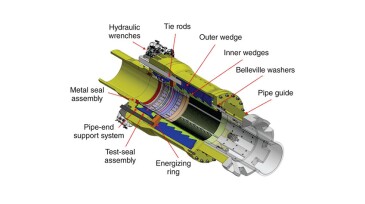

This paper compares traditional welded techniques, such as above-water repair methods and underwater hyperbaric welding, with the novel options offered by subsea connectors purposely developed for corrosion-resistant-alloy-clad pipelines.

-

This paper introduces a technology for offshore pipeline inspection centered on an autonomous robotic system equipped with underwater computer vision and edge-computing capabilities.

-

The offshore industry is actively embracing a digital-first, low-carbon future, supported by scalable demonstrators, intelligent systems, and integrated engineering approaches now entering precommercial or early-deployment stages.

-

Short on skilled welders? For complex jobs like pressure-vessel seams, automation could be the key to keeping production safe, accurate, and on schedule.

-

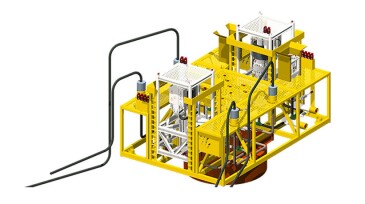

By closely monitoring its subsea boosting system, Shell extended maintenance intervals and safely postponed pump replacement at its ultradeepwater Stones field.

-

With the right infrastructure and interoperability, subsea resident robotics could unlock more frequent, cost-effective inspections—and a new standard for offshore efficiency.

-

Emerging solutions could solve current subsea pain points, while a new taxonomy system could clarify the capabilities of the expanding domain of underwater vehicles.

Page 1 of 17