Inspection/maintenance

The Norwegian major said it is using artificial intelligence for predictive maintenance throughout its facilities and for interpretation of seismic data from the Norwegian continental shelf.

Sponsored

As HPHT wells push equipment to the edge of material limits, operators are turning to advanced thermoplastics and sealed electrical assemblies to maintain system integrity. From ESP insulation to BOP control systems, the right component design can prevent failures, lower intervention costs, and extend equipment life in the harshest offshore environments.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

Successful in other applications, self-healing coatings could be the oil industry’s ticket to fighting corrosion and extending the life of steel.

-

This article presents a results-driven case study from an ongoing collaboration between a midstream oil and gas company and Neuralix Inc.

-

The USV Challenger will be remotely controlled from shore and will be equipped with multiple autonomous features.

-

SLB is introducing a new electric well-control system to replace larger conventional, fluid‑controlled hydraulic equipment.

-

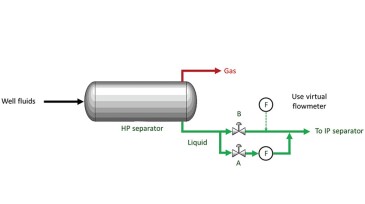

This paper describes the operator’s digital-twin end-to-end production system deployed for model-based surveillance and optimization.

-

Terra Drone will support Aramco's operations and Saudi Arabia's technological and economic progress.

-

A robotic arm, camera system, and virtual reality helped EniProgetti and University of Naples researchers overcome the major challenges of direct-contact nondestructive testing using a drone.

-

Shell’s combination of digital worker technologies enables collaborative troubleshooting and inspections while reducing travel and boosting efficiency.

-

The Louisiana contractor is buying Kystdesign for an undisclosed sum, expanding its underwater vehicle business.

-

This study examines the implementation of a predictive maintenance method using artificial intelligence and machine learning for offshore rotating production-critical equipment. Conducted over 2 years at Murphy Oil’s deepwater platforms in the Gulf of Mexico, the project aimed to detect equipment issues early, reduce downtime, and streamline maintenance processes.