Safety

The company said its frequency of serious incidents was down at the end of the year from its levels at the end of 2024.

This paper examines how real-time monitoring can improve both incident prevention and emergency response in the oil and gas industry. Drawing from real-world examples and case studies, it provides practical strategies for implementing this technology effectively.

This paper presents a novel application of artificial intelligence in computer vision for automating blowout-preventer pressure-chart-data extraction, demonstrating significant efficiency gains and a high return on investment.

-

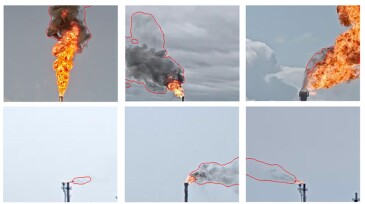

This paper details a data-driven methodology applied in Indonesia to enhance flare-emission visibility and enable targeted reduction strategies by integrating real-time process data with engineering models.

-

This study ascertains the capital expenditure and operating expenditure associated with the reuse of existing facilities, specifically regarding a carbon capture and storage project being prepared in South Korea.

-

SponsoredAdvance your career with the new Pipeline Engineering Program at the Technical University of Leoben, a 5-month course combining on-campus and online learning, integrating industry expertise, engineering practice, and future-ready skills for professionals in oil, gas, and emerging energy systems.

-

A resilience-based approach to safety was the focus of a panel of experts at the 2025 SPE Annual Technical Conference and Exhibition in Houston.

-

This paper focuses on developing a model that can be used in an automated, end-to-end flare-smoke detection, alert, and distribution-control solution that leverages existing flare closed-circuit television cameras at manufacturing facilities.

-

This paper presents a physics-informed machine learning method that enhances the accuracy of pressure transient analysis, predicting reservoir properties to enhance waste slurry injection and waste disposal.

-

Through realistic simulations, virtual reality allows for an unprecedented level of immersion and interactivity that traditional training methods cannot offer.

-

Researchers with the National Energy Technology Laboratory showed that naturally occurring signals in underground fluids can serve as effective indicators of flow patterns between existing wellbores. Understanding these patterns can lead to increased efficiency and safety.

-

This paper explores the integration of human factors engineering principles into rig move planning to enhance safety in the oil and gas industry. It discusses the significance of considering human factors such as fatigue, stress, communication, and decision-making in rig move operations.

-

Short on skilled welders? For complex jobs like pressure-vessel seams, automation could be the key to keeping production safe, accurate, and on schedule.

Page 1 of 66