Oilfield chemistry

Marking a major milestone as the Gulf of Mexico’s second 20,000-psi deepwater development, the project underscores how advanced high-pressure technology, management of flow challenges, and the floating production system’s role as a regional hub are helping open the door to more Inboard Wilcox development.

This paper describes a decision-support system that integrates field data, system specifications, and simulation tools to quantify system performance, forecast operational challenges, and evaluate the effect of system modifications in water management.

This paper demonstrates that high-purity salts of calcium, magnesium, strontium, sodium, and lithium can be recovered from produced-water brine using a chemical-reaction pathway followed by vacuum-driven crystallization and a lithium-extraction process.

-

The authors of this paper aim to design, optimize, and evaluate a scalable and energy-efficient plasma-driven advanced-oxidative-process system for produced-water remediation, emphasizing regulatory compliance for safe discharge or reuse.

-

A new tubing-conveyed tool combines wellbore cleanout with multi-tracer deployment for production diagnostics and reservoir monitoring.

-

This study compares water-based chemicals including surfactants, nanoparticles, and ketones that can be used for enhancing the oil recovery of shale-oil reservoirs.

-

The experience captured in this paper illustrates the potential of deepwater riserless wireline subsea intervention capability and the fact that it can be expanded beyond hydraulic-only, simple mechanical, and plugging-and-abandonment scopes.

-

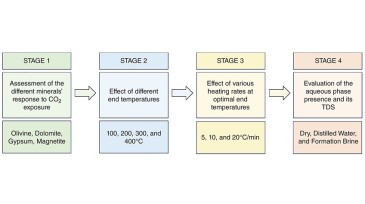

This paper presents a novel methodology for assessing the rapid mineral carbonation of carbon dioxide through geochemical interactions with carbon-, magnesium-, and iron-rich minerals abundant in geological formations.

-

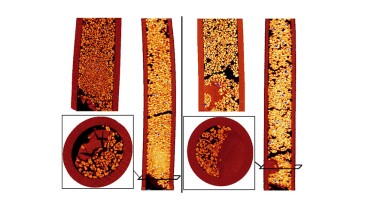

This study contributes to enhancing the understanding of scale-inhibitor retention in rock formations.

-

This paper details the formulation and characterization of a novel nanoparticle system composed of polyethyleneimine and dextran sulfate for direct lithium extraction from bulk oilfield brines in North America.

-

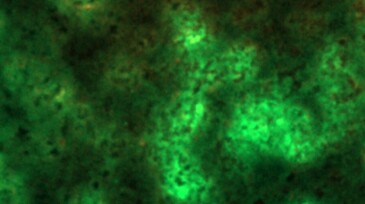

This comprehensive study on microbial control in unconventional facilities allows for the integration of molecular microbiology, chemical treatments, and production engineering to develop specific strategies to control microbial communities and reduce corrosion rates that affect the integrity of the facilities.

-

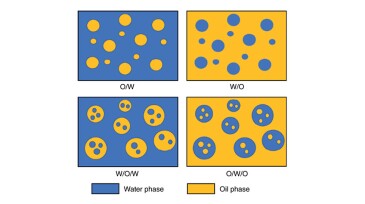

This study presents the development of a novel modeling tool designed to predict condensate emulsions, focusing on key factors causing emulsions such as pH, solid content, asphaltene concentration, droplet size, and organic acids.

-

This paper describes a case history in the UAE in which the cleanout of scale contaminated with naturally occurring radioactive material was conducted successfully.

Page 1 of 15