Coiled tubing

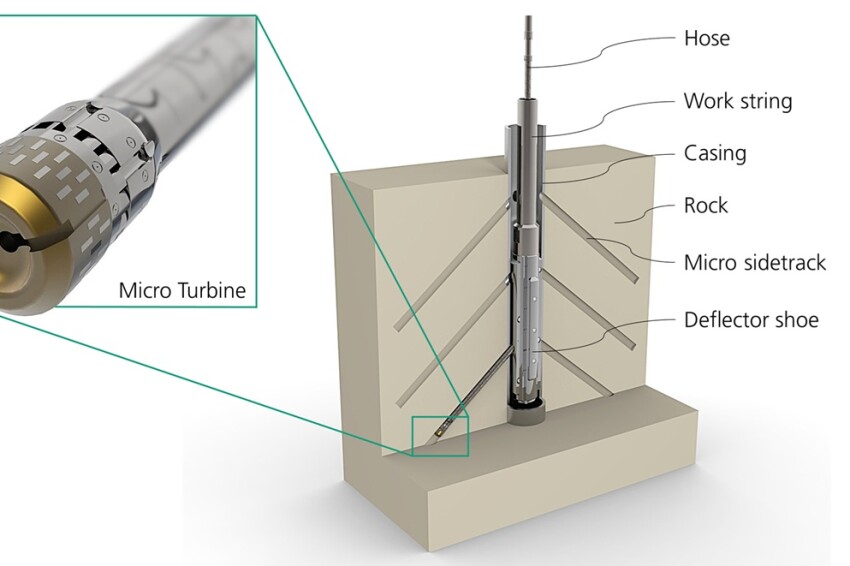

A field test study examines micro turbine drilling in a clay formation that allows steel casing and formation to be drilled in a single operation.

This study explores enhancing gas production through a novel combination of prestimulation using a coiled tubing unit and high-rate matrix acidizing.

This paper describes the use of coiled tubing in a pilot project for carbon dioxide injection, enabling evaluation of the conversion of an existing oil field for CCS purposes and derisking storage-development uncertainties before having to cease hydrocarbon production.

-

This paper describes the first riserless coiled tubing services operation performed in a live subsea well and the associated improvements in efficiency, cost savings, and safety.

-

This paper describes a case history in the UAE in which the cleanout of scale contaminated with naturally occurring radioactive material was conducted successfully.

-

Each of these papers presented at SPE conferences exemplifies engineering solutions to maximize commercial value while retaining focus on HSE and service quality.

-

TechnipFMC, in collaboration with Halliburton, was awarded the 2025 ICoTA Intervention Technology Award and received the 2025 Curtis Blount Outstanding Paper Award.

-

Given the diversity of coiled tubing well-intervention data, many acquisition labels are often missing or inaccurate. The authors of this paper present a multimodal framework that automatically identifies job type and technologies used during an acquisition.

-

SponsoredTAQA is commencing its journey into the year 2024 with the successful launching of many innovative coiled tubing technologies and solutions, technologies that will transform the nature of well intervention operations into a new era. Read this article and dive into the high-tier coiled tubing technology offerings from TAQA.

-

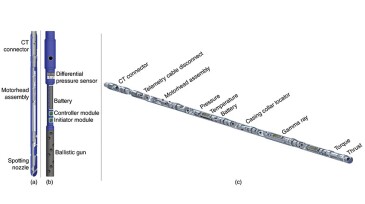

This study highlights the strategic implementation of coiled tubing to convey perforating guns in extended-reach wells, overcoming the lockup effect through the deployment of downhole tractors and real-time monitoring tools.

-

The advances presented in the selected papers, and many others, would not be possible without improvements in our understanding of materials, how to protect coiled tubing pipes, how to get the best performance out of them under downhole conditions that are becoming every day more extreme, and how to preserve wellbore completion at the same time.

-

This study emphasizes the vital need to evaluate well conditions and working-fluid compatibility with coiled tubing materials to prolong coiled tubing operational life.

-

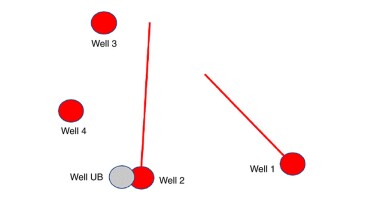

This paper describes the application of an underbalanced coiled tubing technology in tight sandstones, using an integrative approach that incorporates petrophysical, geophysical, and reservoir engineering data.

Page 1 of 7