Coiled tubing

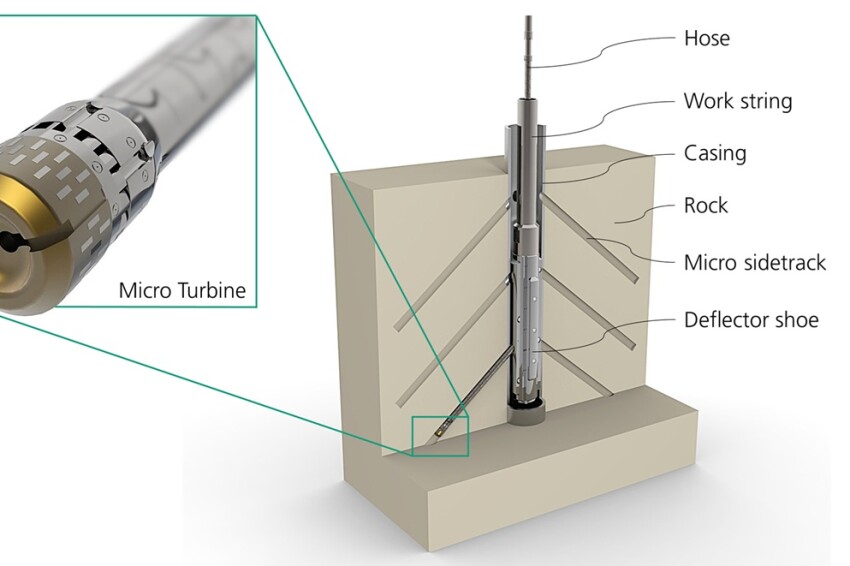

A field test study examines micro turbine drilling in a clay formation that allows steel casing and formation to be drilled in a single operation.

This study explores enhancing gas production through a novel combination of prestimulation using a coiled tubing unit and high-rate matrix acidizing.

Each of these papers presented at SPE conferences exemplifies engineering solutions to maximize commercial value while retaining focus on HSE and service quality.

-

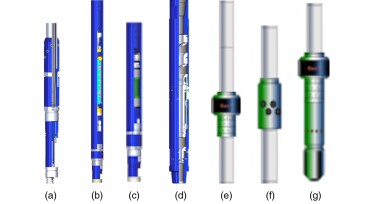

This study illustrates how a combination of a straddle-packer system and a downhole real-time telemetry successfully stimulated up to 38 stages while maintaining packer-seal integrity and downhole pressure.

-

The authors of this paper describe an underbalanced coiled-tubing drilling campaign in the operator’s onshore fields using a closed-loop system design.

-

The authors describe a casing-leak-repair alternative to allow continued hydraulic fracturing of an unconventional formation.

-

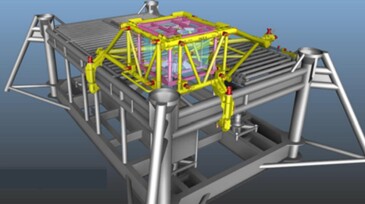

The authors describe coiled tubing operations that used a riser on a monohulled vessel already performing riserless interventions.

-

Coiled tubing has a key role to play, with strong arguments for itself: It is used throughout the life of a well, from exploration to abandonment, and its flexibility of use, combined with recent technology developments in pipe materials, real-time downhole telemetry, and specialized downhole tools—just to name a few—opens avenues to perform in a rigless manner many o…

-

A leaner and wiser Weatherford seeks new Middle East contracts while growing margins and market share on existing business.

-

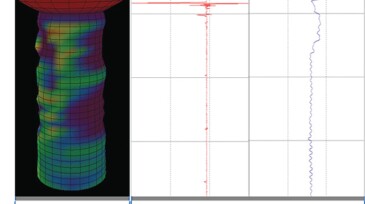

The authors describe the applicability of 110,000-psi yield-strength quench-and-tempered coiled tubing strings in high-pressure sour environments through implementation of a custom-fit coiled tubing integrity and risk-mitigation program.

-

This paper describes a new concept for a reel mover used for coiled tubing deployment and operation.

-

In this year’s feature are two case histories and an equipment-development paper, all of which are, by accident rather than design, from operations undertaken in the Gulf States. Each, in its own way, exemplifies the engineering decisions and balances that must be weighed to provide the best solution within limiting parameters and the considerable effort this may take…

-

This paper illustrates a novel methodology that enabled the safe application of coiled tubing abrasive perforation to increase production in a sour horizontal extended-reach oil producer.