The complete paper illustrates a novel methodology that enabled the safe application of coiled tubing (CT) abrasive perforation to increase production in a sour horizontal extended-reach (ER) oil producer. The well was underperforming at 10% of the anticipated production rate because of a damaged lower completion. To avert a costly workover, abrasive perforation with CT was selected as a safe alternative to conventional explosives-based perforating conveyed on electric line.

Introduction

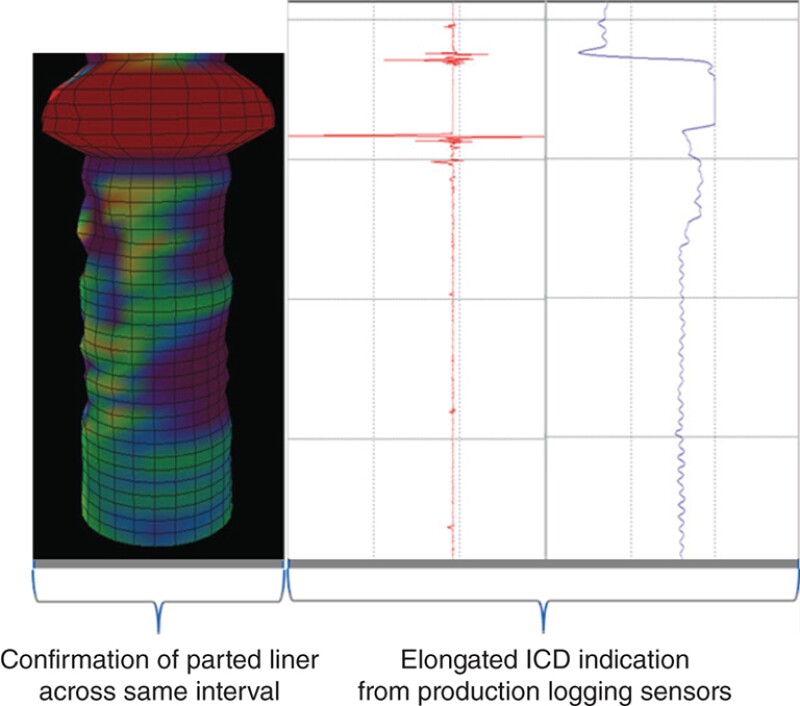

An offshore horizontal ER producer well was drilled with a total depth (TD) in excess of 24,000‑ft measured depth (MD). During the completion phase, a 4.5-in. liner with 16 inflow control devices (ICDs) and eight swellable packers was run with the ICDs in the closed position.