Drilling automation

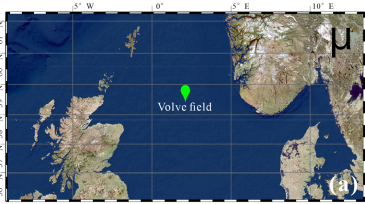

In this study, a method was developed to analyze the effects of drilling through transitions on bit-cutting structures and construct an ideal drilling strategy using a detailed drilling model.

This paper describes a machine-learning approach to accurately flag abnormal pressure losses and identify their root causes.

This research aims to develop a fluid-advisory system that provides recommendations for optimal amounts of chemical additives needed to maintain desired fluid properties in various drilling-fluid systems.

-

The SPE Drilling Systems Automation Technical Section has a new name—and a bigger mission. Discover how DSATS is evolving beyond automation to drive smarter, more connected, and more human-centered drilling systems for the future.

-

This paper presents the development of a digital tool for automatically analyzing the readiness of a borehole to accept casing. The tool integrates data-driven and physics-based models to indicate locations of risk along the wellbore.

-

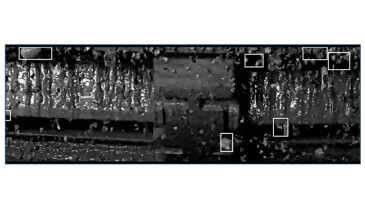

This paper describes an experimentation trial deploying and operating a computer-vision system on a deepwater rig to measure drilled cuttings in real time using a remotely monitored camera system.

-

This article is the fourth in a Q&A series from the SPE Research and Development Technical Section focusing on emerging energy technologies. In this piece, David Reid, the CTO and CMO for NOV, discusses the evolution and current state of automated drilling systems.

-

The agreement focuses on improving operational efficiency and consistency through advanced digital tools and real-time data integration.

-

An innovative approach uses a random-forest-based framework to link logging-while-drilling and multifrequencey seismic data to enable dynamic updates to lithology parameter predictions, enhancing efficiency and robustness of geosteering applications.

-

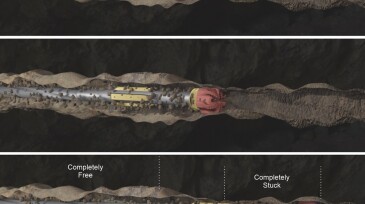

This comprehensive review of stuck pipe prediction methods focuses on data frequency, approach to variable selection, types of predictive models, interpretability, and performance assessment with the aim of providing improved guidelines for prediction that can be extended to other drilling abnormalities, such as lost circulation and drilling dysfunctions.

-

New case studies highlight how artificial intelligence, advanced hardware, and innovative business models are enabling success in drilling automation.

-

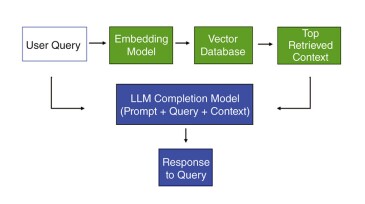

This paper tests several commercial large language models for information-retrieval tasks for drilling data using zero-shot, in-context learning.

-

Leading drilling consultant John de Wardt separates hype from reality and explores what’s ahead in this interview with JPT.

Page 1 of 16