Drilling automation

Autonomous drilling through managed pressure drilling (MPD) at the Atlantis field has given the operator confidence to scale the method.

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

This paper proposes a novel approach toward drilling maximum-reservoir-contact wells by integrating automated drilling and geosteering software to control the downhole bottomhole assembly, thereby minimizing the need for human intervention.

-

New case studies highlight how artificial intelligence, advanced hardware, and innovative business models are enabling success in drilling automation.

-

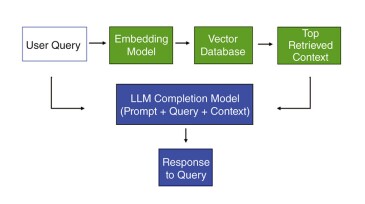

This paper tests several commercial large language models for information-retrieval tasks for drilling data using zero-shot, in-context learning.

-

Leading drilling consultant John de Wardt separates hype from reality and explores what’s ahead in this interview with JPT.

-

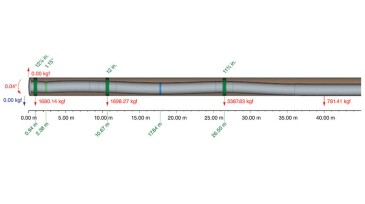

In this paper, bottomhole-assembly lateral behavior is analyzed using different types of computations, including static, dynamic, frequency-based, and time-based.

-

Digitalization and automation of the drilling process drive the need for an interoperability platform in a drilling operation, where a shared definition and method of calculation of the drilling process state is a fundamental element of an infrastructure to enable interoperability at the rigsite.

-

This paper highlights a new online system for monitoring drilling fluids, enabling intelligent control of drilling-fluid performance.

-

Technology uptake aimed at optimizing resources, delivering consistency, and augmenting what humans can do.

-

We’re thrilled to announce the launch of the 2025 SPE/JPT Drilling and Hydraulic Fracturing Technology Review. This exclusive, official publication will be distributed at three major SPE industry events.

-

This paper delves into the evolving landscape of drilling automation, emphasizing the imperative for these systems to go beyond novelty and deliver quantifiable financial value.

-

The company has agreed using its innovations in automation in an effort to derisk ultradeep offshore drilling for the Brazilian national oil company.