Drilling automation

Autonomous drilling through managed pressure drilling (MPD) at the Atlantis field has given the operator confidence to scale the method.

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

This paper proposes a novel approach toward drilling maximum-reservoir-contact wells by integrating automated drilling and geosteering software to control the downhole bottomhole assembly, thereby minimizing the need for human intervention.

-

The RoboWell technology for well control will be available globally through Halliburton’s Landmark iEnergy hybrid cloud.

-

A universal, automated approach to condition-based maintenance of drilling rig mud pumps is developed using acoustic emission sensors and deep learning models for early detection of pump failures to help mitigate and reduce costs and nonproductive time generally associated with catastrophic pump failures.

-

The SPE Drilling and Wells Interoperability Standards group proposes a dual-path strategy to overcome the technical and commercial barriers facing the advancement of drilling automation.

-

This paper describes an autonomous drilling approach using an autocurve-drilling mode to automatically drill curved sections without human intervention and complete autonomous well construction.

-

This paper presents an approach for automatic daily-drilling-report classification that incorporates new techniques of artificial intelligence.

-

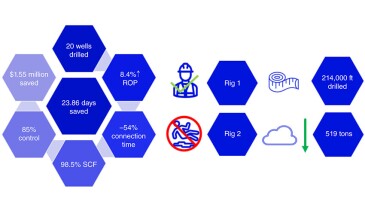

The authors of this paper present the results of implementing a rig-automation solution applied to 20 wells in Ecuador in 2022.

-

The oilfield service giant said it has taken another big step toward fully autonomous drilling operations in its latest project offshore Brazil.

-

The companies have integrated their platforms in an effort to increase flexibility and interoperability.

-

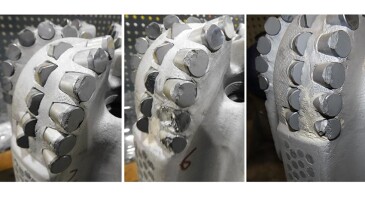

This paper describes an 18-month intensive continuous improvement process between an operator, a rig contractor, and bottomhole-assembly (BHA) service providers aimed at reducing BHAs per well in two Oklahoma rigs.

-

This paper presents the study, resulting recommendations, and a proposed change in standard bottomhole-assembly configurations to reduce service-quality-compromising incidents and productive time lost from jar twistoffs.