Processing systems/design

The $100-billion project is widely considered the largest unconventional development outside of the US and is noted by Aramco as the largest nonassociated gas development in the kingdom.

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

This study ascertains the capital expenditure and operating expenditure associated with the reuse of existing facilities, specifically regarding a carbon capture and storage project being prepared in South Korea.

-

This paper describes the development of a system for comprehensive mapping and asset registration using a digital-twin approach.

-

BPX Energy will retain operatorship of the assets after the sale of its interests to private investment firm Sixth Street is complete.

-

BP’s new electric gas compression platform at Shah Deniz, Azerbaijan’s largest natural gas producer, is expected to sustain exports to Europe even as the field enters decline.

-

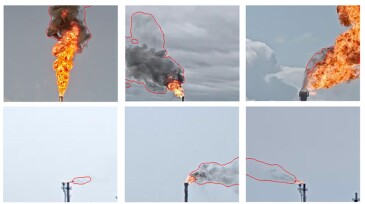

This paper focuses on developing a model that can be used in an automated, end-to-end flare-smoke detection, alert, and distribution-control solution that leverages existing flare closed-circuit television cameras at manufacturing facilities.

-

This study recommends favoring the combustion of ammonia over hydrogen for the purpose of reducing CO₂ and nitrogen emissions.

-

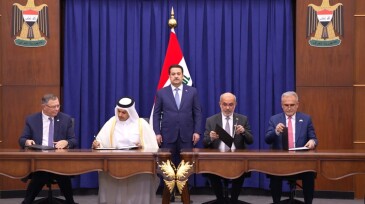

Iraq’s Gas Growth Integrated Project aims to increase electricity generation by capturing flare gas collected from three southern oil fields. A desalination project will use treated seawater to maintain well pressures.

-

Louisiana-based project will use operator’s Optimized Cascade process to turn feed gas into LNG.

-

This paper reviews lean construction management processes adopted in the Apani Field development, from facility design to construction management and drilling-location preparation.

-

In this final installment of the Savvy Separator Series (No. 23), the authors present a curated collection of recommended references, articles, and other key resources—a comprehensive guide worth reading, bookmarking, and keeping in your library.

Page 1 of 15