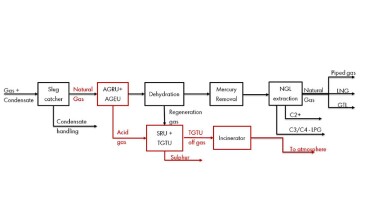

Processing systems/design

The $100-billion project is widely considered the largest unconventional development outside of the US and is noted by Aramco as the largest nonassociated gas development in the kingdom.

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

Short on skilled welders? For complex jobs like pressure-vessel seams, automation could be the key to keeping production safe, accurate, and on schedule.

-

As LNG projects sanctioned earlier this decade come onstream, a shortage of new final and pre-final investment decisions threatens to leave the project pipelines dry at a time when global LNG demand is forecast to surge over the next 15 years.

-

With the right internal modifications, traditional degassers can be enhanced with gas flotation for improved oily water separation. This article outlines key design considerations—including inlet and settling zones, skimming, and solids handling. Two case studies highlight lessons learned in troubleshooting and revamping degasser designs.

-

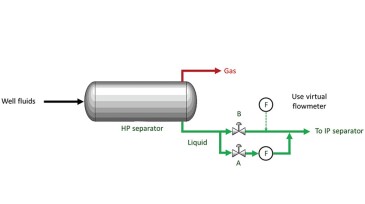

This paper describes the operator’s digital-twin end-to-end production system deployed for model-based surveillance and optimization.

-

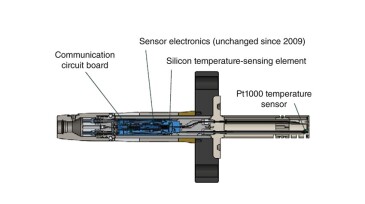

The authors of this paper describe a project to develop a virtual sensor to monitor the cooling effect downstream of a subsea choke to avoid hydrate plugs during cold-start operations.

-

First LNG at Tellurian’ asset known as Driftwood LNG before Woodside’s acquisition last year is expected in 2029.

-

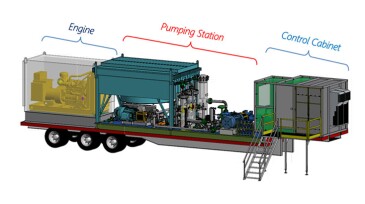

This article describes a technology combining a compression unit with a flexible line to offer a flaring alternative for transferring hydrocarbons.

-

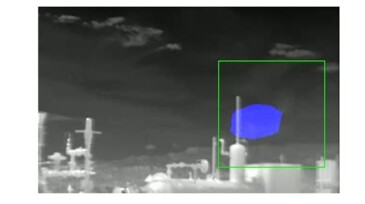

This paper describes a deep-learning image-processing model that uses videos captured by a specialized optical gas-imaging camera to detect natural gas leaks.

-

This paper aims to provide insights to address the challenge of identifying the optimal point within the gas-processing lineup for recovering a high-purity CO₂ stream suitable for sequestration.

-

This article is the second of a two-part series on produced-water management in the Gulf of Mexico and covers four themes: equipment, process configuration, operations, and effluent quality.