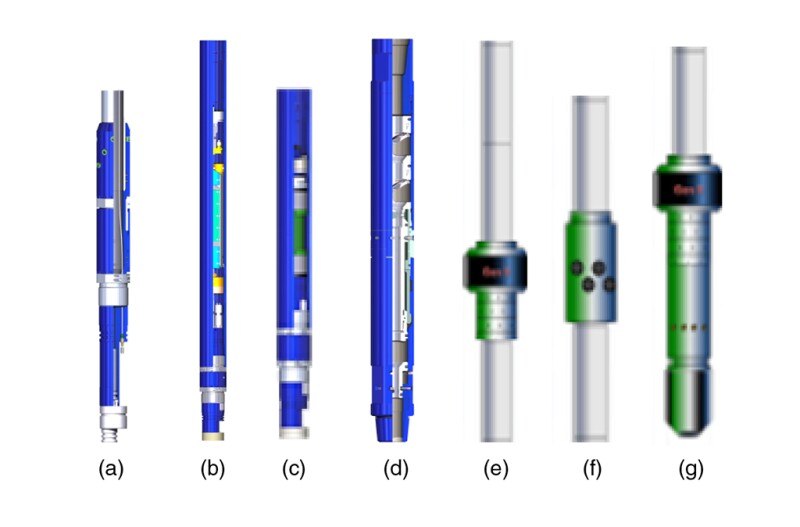

The authors describe in the complete paper how the combination of a straddle-packer system and a downhole real-time telemetry system was used to acid-stimulate up to 38 stages successfully and monitor the behavior of the straddle packer continuously during diversion of multistage acid treatment of screens while maintaining packer-seal integrity and downhole pressure. In addition, the study also provides lessons learned from implementation of multistage packers with real-time telemetry for successful diversion of acid treatment uniformly across screens in a horizontal well.

Introduction

Use of inflow control devices (ICDs) is a preferred completion technique in producing multilayer reservoirs from a single well while allowing the optimal production profile along the completed intervals by managing the drawdown from the reservoir to the wellbore. This study focuses on controlled acid treatment of a high number of ICDs in a single well.

Two options existed for achieving optimal acid placement in the subject well with 38 ICDs during treatment, chemical and mechanical diversion. Mechanical diversion is the preferred option because it ensures the most-accurate fluid diversion during stimulation.