Drilling/completion fluids

Two critical facets of the discipline of well control and wellbore integrity—decarbonization and groundbreaking automation of essential processes—are highlighted in the three primary paper selections presented at SPE and SPE-affiliated conferences during the past year.

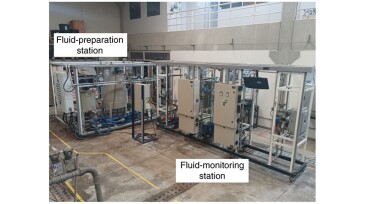

This research aims to develop a fluid-advisory system that provides recommendations for optimal amounts of chemical additives needed to maintain desired fluid properties in various drilling-fluid systems.

This paper describes development of a high-temperature water-based reservoir drill-in fluid using a novel synthetic polymer and customized with optimal chemical concentrations and sized calcium carbonate.

-

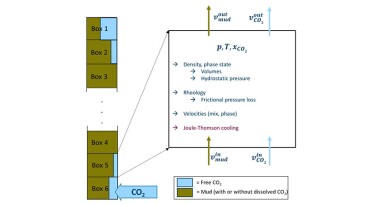

This paper aims to close some of the many knowledge gaps that exist in the field of drilling CO₂ storage wells, a task that is expected to involve handling an influx of CO₂ into the drilling fluid.

-

We’re thrilled to announce the launch of the 2025 SPE/JPT Drilling and Hydraulic Fracturing Technology Review. This exclusive, official publication will be distributed at three major SPE industry events.

-

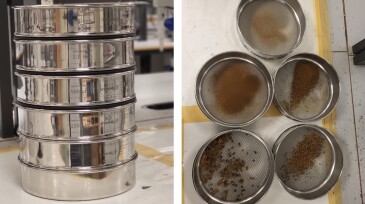

A fundamental research study is conducted to confirm the potential usefulness of chelating agents in dispersing settled barite, emphasize the complex nature of the factors that control this process, and provide a solid basis for future studies aimed at optimizing dispersion methods in industrial applications.

-

A universal, automated approach to condition-based maintenance of drilling rig mud pumps is developed using acoustic emission sensors and deep learning models for early detection of pump failures to help mitigate and reduce costs and nonproductive time generally associated with catastrophic pump failures.

-

Computational fluid dynamics modeling is used to gain better understanding of filter-cake formation in inclined and vertical well drilling operations under elevated temperature and pressure, highlighting the importance of controlling fluid invasion to optimize drilling performance.

-

This paper details a gravel packing operation in the Martin Linge field in the North Sea that marks the highest density carrier fluid openhole gravel pack completed successfully worldwide, setting a new standard for well completions in challenging high-pressure environments.

-

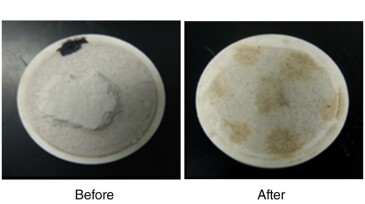

This paper describes results of a study indicating that an enzyme/in-situ organic acid generated cleanup system was effective at degrading filter cake for a water-based-mud field sample, reflected in the obtained return permeability of nearly 83%.

-

Typically, oil and gas producing wells are abandoned toward the end of their life cycles with reservoir pressures depleted compared with the virgin pressures. Carbon capture and storage projects, however, present different operating conditions.

-

This paper presents the concept of a supervisory and advisory system dedicated to support the detection of abnormal events and to provide guidelines for fluid treatment.

-

This paper describes the success of using a new low-equivalent-circulating-density organophilic clay-free inverted emulsion fluid in gas reservoirs at elevated temperatures and with differential pressures up to 4,500 psi.