Drilling/completion fluids

Two critical facets of the discipline of well control and wellbore integrity—decarbonization and groundbreaking automation of essential processes—are highlighted in the three primary paper selections presented at SPE and SPE-affiliated conferences during the past year.

This research aims to develop a fluid-advisory system that provides recommendations for optimal amounts of chemical additives needed to maintain desired fluid properties in various drilling-fluid systems.

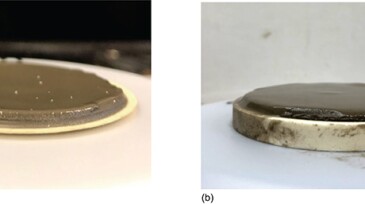

This paper describes development of a high-temperature water-based reservoir drill-in fluid using a novel synthetic polymer and customized with optimal chemical concentrations and sized calcium carbonate.

-

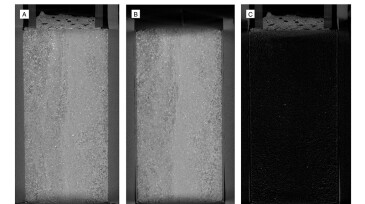

This paper describes a systematic full-scale test program to study and optimize solids-control efficiency with hollow-glass-beads drilling fluids.

-

At every stage, well-construction projects must be concerned about those aspects to establish measurable barriers for preventing issues. Therefore, drilling and completion fluids are critical for achieving project goals and ensuring operations are executed as planned.

-

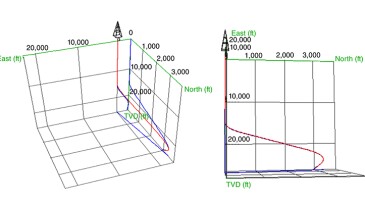

This paper describes an openhole wireline-logging operation in a deepwater Gulf of Mexico well in a high-pressure/high-temperature slimhole environment using water-based reservoir drilling fluid.

-

The authors of this paper present results of a study that examined formation-damage mechanisms caused by drilling fluids in tight reservoirs in onshore oil fields in Abu Dhabi.

-

This paper reviews the successful application of a mud-cooling and managed-pressure-drilling system in a high-pressure/high-temperature well to explore the potential of a Mesozoic carbonate platform in the Nile Delta of Egypt.

-

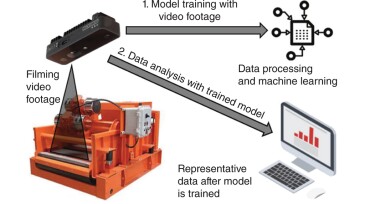

The authors of this paper describe a project that demonstrated the feasibility of using deep-learning and machine-learning approaches to introduce camera-based solids monitoring to the drilling industry.

-

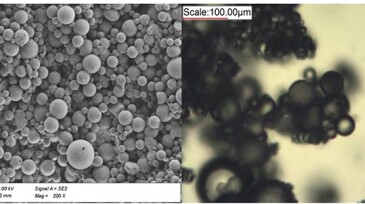

In this paper, β-cyclodextrin polymer microspheres, generally used for drug release and wastewater treatment, are evaluated as an environmentally friendly ultrahigh-temperature filtration reducer.

-

This paper describes the qualification and first deepwater drilling application of a novel aqueous reservoir drilling fluid at temperatures greater than 320°F.

-

Significant reserves additions may be realized if the risks associated with drilling in such harsh conditions can be managed effectively. Design and development of a new generation of drilling fluids able to fulfill all of the attributed functions under extreme pressure and temperature conditions is one of the key requirements for unlocking these resources.

-

This paper describes a high-density high-pressure/high-temperature brine-based drilling fluid that provides long-term stability and solids-suspension properties for extended periods of time.