Drilling/completion fluids

Two critical facets of the discipline of well control and wellbore integrity—decarbonization and groundbreaking automation of essential processes—are highlighted in the three primary paper selections presented at SPE and SPE-affiliated conferences during the past year.

This research aims to develop a fluid-advisory system that provides recommendations for optimal amounts of chemical additives needed to maintain desired fluid properties in various drilling-fluid systems.

This paper describes development of a high-temperature water-based reservoir drill-in fluid using a novel synthetic polymer and customized with optimal chemical concentrations and sized calcium carbonate.

-

This paper discusses the results of extensive laboratory tests used for the customization of a reservoir drill-in fluid and a delayed breaker—and their field performance—for two deepwater gas-injector wells.

-

Against a backdrop of global uncertainty and challenging economics, well integrity subject-matter experts have continued to prioritize human and environmental safety in production while pivoting their skills toward areas of growing importance such as carbon capture and sequestration. New technologies and simulation methods have allowed the authors of the three SPE pap…

-

Recent developments in drilling-systems automation provide a multitude of opportunities to have real-time monitoring of drilling-fluid properties and early diagnosis of drilling-fluid-related complications that might arise while drilling. Coupled with closed-loop control of surface and downhole drilling-fluid properties, automated monitoring of fluid properties would …

-

This paper presents experiences from an automated drilling-fluids-monitoring initiative and resulting real-time hydraulic measurements and models for automatic drilling control.

-

This paper presents the design and functionality of an apparatus that measures directly and automatically the pressure/volume/temperature (PVT) behavior of the drilling fluid contained in a pit.

-

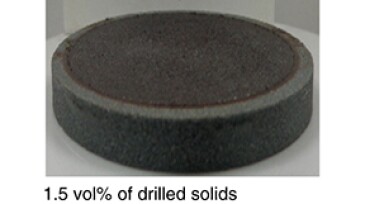

In this paper, alternative approaches to solids characterization are presented that lend themselves better to automation and real-time monitoring than API retort measurement.

-

Few industries contain as many phases, steps, and levels of interface between the start and end product as the oil and gas industry. It therefore is hardly surprising that communication, in all its varied forms, is at the very heart of our business.

-

SponsoredBefore you pump materials down your well, be sure you fully understand the effectiveness of your friction reducers and gas migration slurries.

-

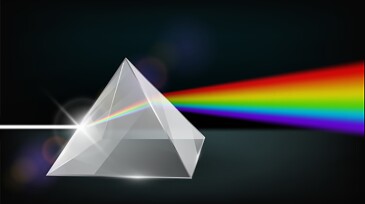

Fluid identification, a critical process in fluid sampling, continues to be a challenge in temperatures above 350°F. At temperatures up to 450°F, fluid identification is currently achieved by bubblepoint and compressibility measurements, which cannot quantitatively measure contamination levels of the sample fluid. A possible solution involves using pyroelectric detect…

-

The qualification and first deployment of a low-solids, oil-based completion fluid that incorporates a newly developed, high-density brine as the internal phase to extend the density limit is discussed.