Drilling/completion fluids

Two critical facets of the discipline of well control and wellbore integrity—decarbonization and groundbreaking automation of essential processes—are highlighted in the three primary paper selections presented at SPE and SPE-affiliated conferences during the past year.

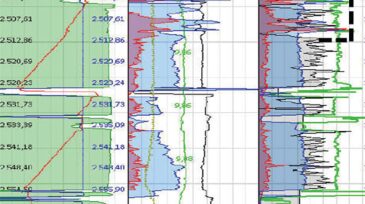

One major challenge for drilling-fluid engineers is the design and management of optimal drilling-fluid formulations in emerging frontiers—fractured formations and high-pressure geothermal environments. Recently, operators have leveraged cutting-edge technology such as machine learning and expanded data-driven techniques to facilitate the development of new drilling-f…

This research aims to develop a fluid-advisory system that provides recommendations for optimal amounts of chemical additives needed to maintain desired fluid properties in various drilling-fluid systems.

-

S13Cr tubing specimens experienced stress corrosion cracking with phosphate-based completion fluids contaminated with mud and oxygen, whereas formate-based completion fluid is compatible with the tubing.

-

There is a growing interest in using nanocomposites to improve drilling-fluid rheology. In recent years, an additive derived from a sequence of graphene-based materials has been reported. The progress of these graphene derivatives has been used as a paradigm for water-based drilling fluids.

-

Advances during the past decade in using convolutional neural networks for visual recognition of discriminately different objects means that now object recognition can be achieved to a significant extent.

-

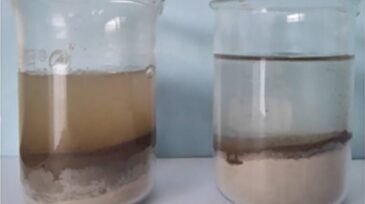

This paper reports the effect of sodium dodecyl sulfate modified graphene (SDS-Gr) on the rheological features, fluid loss, and swelling inhibition mechanism of clay.

-

This paper describes a low-impact, nonaqueous drilling fluid (LIDF) designed to minimize equivalent circulating density (ECD) increases and associated risks in deep water by reducing the effect of cold temperature on fluid viscosity.

-

This paper discusses a new, comprehensive cuttings-transport model designed to enable safe and improved hole-cleaning operations.

-

While drilling in deepwater Gulf of Mexico, a topdrive failure forced the shutdown of all drilling operations for the rig operator and lasted for 114 hours.

-

This paper covers the 7-year history of drilling-fluids application in a reservoir drilling campaign offshore Abu Dhabi, from the early use of a solids-free, brine-/water-based mud to the recent application of nondamaging, nonaqueous fluids (NAFs) with micronized acid-soluble ilmenite.

-

This study focus on the design and evaluation of a customized water-based mud (NP-WBM) using silica oxide nanoparticles (SiO2-NPs) and graphene oxide nanoplatelets (GNPs).