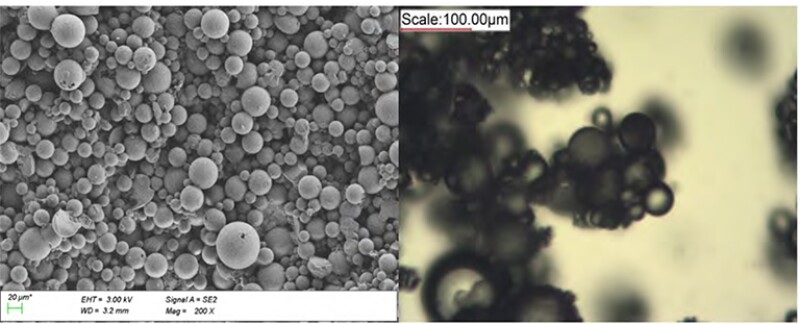

Because of the rapid degradation of conventional biopolymer or synthetic polymeric additives at high temperatures (HT) or ultra-HT, effective control of water-based drilling-fluid filtration in these environments remains a major challenge in drilling operations. In the complete paper, β-cyclodextrin polymer microspheres (β-CPMs), generally used for drug release and wastewater treatment, have been evaluated and found to be effective, environmentally friendly ultra-HT filtration reducers.

Experimental Methods

Sodium bentonite (16 g) and deionized water (400 mL) was homogenized by stirring at 10,000 rev/min for 30 minutes. After hydration for another 24 hours, the suspension, which would be the base mud, was ready for use. β-CPMs were mixed into the base mud and hot rolled under temperatures ranging from 120 to 240°C for 16 hours.