The handling of produced water from unconventional reservoirs calls for tailored methodologies crucial for its containment. These methods maintain the longevity of the environment from a multitude of angles, discussed in this article.

Purpose of Integrating Modern Methodology

When dealing with unorthodox reservoirs, various factors must be considered during the process of resource extraction. Fundamental differences in the geological composition of these unconventional reservoirs necessitate varied extraction methods. When using a typical extraction method, the gas rises from the source rocks where it originated and gathers beneath a layer of impermeable rock, where it may be pumped out. In unconventional reservoirs, the gas is contained within the source rocks and must be released by breaking them down in an alternative manner. The most common technique combines horizontal drilling and hydraulic fracturing to enable the resource to rise to the surface.

Horizontal drilling begins by drilling vertically into the source rock, then gradually turning horizontally to access a greater area of extraction, increasing the potential yield from the resource-rich rock. Hydraulic fracturing is then employed, utilizing a high-pressure liquid mixture that creates fractures inside the rock, allowing resources to flow more freely into the wellbore. Fig. 1 compares conventional and unconventional drilling processes.

To effectively break down the source rock, a large amount of water is necessary. The volume of water per well can range from around 1.5 million gallons to 15 million gallons. The sheer volume of water is related to the amount of produced water that surfaces, with roughly 10 to 20% of the injected water returning to the surface as flowback within the first few weeks.

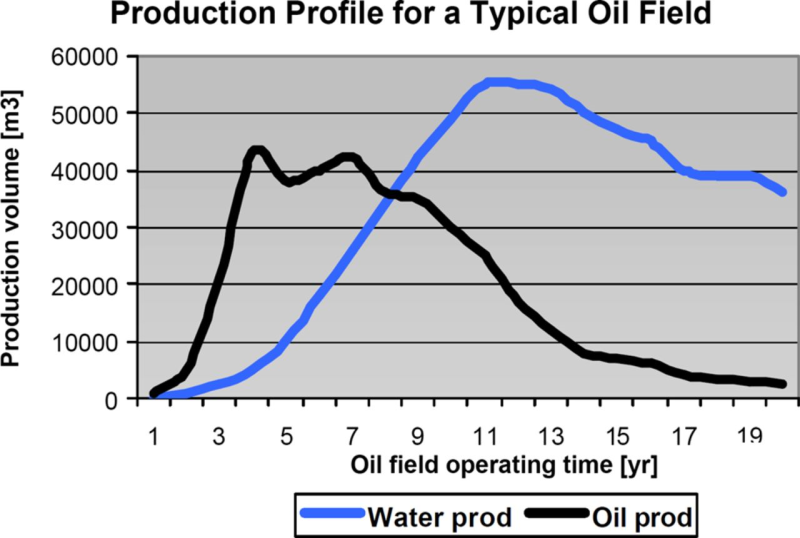

Reservoirs such as shale gas, tight gas, and coalbed methane have complex compositions with higher contaminant levels in the produced water. These contaminants include not only hydrocarbons and salts but also chemicals from the hydraulic fracturing process, heavy metals, and sometimes naturally occurring radioactive materials. The contaminants and the magnitude of water surfacing necessitate advanced treatment technologies to ensure safe reuse or disposal. Fig. 2 indicates the water produced in comparison to oil production.

Developments in Approach

There are many approaches to treating produced water, with some methods more commonly used. One of the most widely used methods for treatment is advanced filtration. Membrane filtration technologies, such as reverse osmosis (RO) and nanofiltration, are employed to remove a high percent of contamination. RO begins with pretreatment, where larger particles are removed through sedimentation and microfiltration, and chemicals are used to prevent scaling. The pretreated water is then pumped through a semipermeable membrane, which separates the permeate (clean water) and concentrate (waste). While RO is deemed effective, it requires a high amount of energy, extensive membrane maintenance, and careful disposal of the concentrate (Fig. 3).

Another approach is electrocoagulation which utilizes electrical currents to destabilize and aggregate contaminants such as oils, heavy metals, and suspended solids. The electrical currents cause the contaminants to clump together, forming larger particles that can be easily separated from the water. For specific contaminants in the water, electrocoagulation is the preferred choice of treatment.

Biological treatments manage produced water by harnessing natural processes. Bioreactors use microorganisms to degrade organic contaminants and come in two forms: aerobic bioreactors that require oxygen and anaerobic bioreactors that operate without it. Aerobic bioreactors efficiently break down biodegradable organic matter, while anaerobic bioreactors produce biogas, a renewable energy source, during treatment.

Constructed wetlands are artificially created to mimic natural wetlands by integrating plants, soil, and microbes to filter and break down pollutants. These systems are efficient at removing heavy metals, organic compounds, and nutrients. Biological treatments are cost-effective and sustainable, making them valuable for reusing or disposing of produced water, while also providing environmental benefits as a byproduct of treatment.

The Correctional Influence of Protocols and Guidelines

To further propel the integration of effective treatment methodologies for produced water, stringent regulations and acts are implemented to enforce their use. The Clean Water Act (CWA) sets the framework for regulating discharges into surface waters. The CWA makes it unlawful to discharge any pollutant from a point source into surface waters without authorization by a National Pollutant Discharge Elimination System (NPDES) permit or other specified statutory provisions. The commitment to protecting bodies of water by the NPDES is enforced through permit requirements, monitoring, and controlling pollutants discharged from point sources. The Environmental Protection Agency (EPA)’s NPDES permit regulations require permit holders to report compliance with NPDES permit limits via periodic Discharge Monitoring Reports submitted to the permitting authority. An NPDES permit must include any applicable technology-based effluent limitations. Additionally, if there is a reasonable potential to cause or contribute to an exceedance of water-quality standards, the permit must also include additional water-quality-based effluent limitations.

Effects of the Collective

The combined variables in dealing with produced water, the repercussions, influence on long-term environmental standing, and the enforcement of acts push for the

utilization of advanced approaches. Modern approaches are not used in isolation; expansions in understanding are driving users to combine methods into sequences that can filter water even further. The realization of potential consequences is altering how we deal with produced water. Institutions were created and still exist today specifically to make produced water reusable or safe to dispose of. The world is pushing for constant change to protect the future and maintain practices within the field. It is inevitable that a near-universal population of those dealing with unconventional reservoirs will implement these advanced methods to higher levels.

For Further Reading

Oilfield-Produced Water Characteristics and Treatment Technologies: A Mini Review by A. Abbas, H. Gzar, M. Rahi.

Hydraulic Fracturing & Health, National Institute of Environmental Health Sciences.

Produced Water: Oil and Gas Terminology Glossary, Water Environment Federation.

What is Produced Water? American Geosciences Institute