Technology

Over the past decade, oilfield service companies have transformed logging-while-drilling (LWD) development into a faster, collaborative, system-level process that delivers improved reliability from the first run and makes development philosophy as important as the technology itself.

Saipem's center includes a full-scale simulator designed to replicate real operational scenarios to deliver an immersive training experience.

EZOps will integrate its Mobile Oilfield Management platform into the college’s energy technology program, giving students hands-on experience with digital tools used in modern oilfield operations.

-

Europe’s largest onshore oil field, the Patos-Marinza in southern Albania, has been given a new lease on life after seeing production soar from 600 B/D just over a decade ago to more than 20,000 B/D this year.

-

In the realm of enabling technologies, multiphase flow modeling has proven to be one of the most important to the oil and gas industry. Without it, nearly all subsea wells would be too costly or dangerous to develop.

-

The amazing rate of improvement in computing technology provides numerous opportunities for improving our operations, but unless the data from various systems can be integrated, it won't deliver on its potential.

-

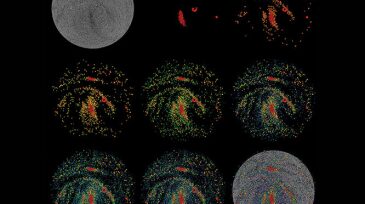

An ongoing research project started nearly 3 years ago by the US Department of Energy’s National Energy Technology Laboratory (NETL) is shedding new light on what really happens to foamed cement as it is pumped deep down offshore wells during completions.

-

Cementing operations represent one of the more critical aspects concerning well integrity.

-

The three Ps that successful companies get right are: people, portfolio, and performance. And you cannot have one without the other. Great people select great portfolios and great portfolios deliver great performance.

-

The rapid development of shale formations over the past decade has led the United States to become the world’s undisputed leader in natural gas production.

-

Making hole has become a more difficult and complex operation as operators move into untapped horizons, especially deepwater and unconventional fields.

-

In April, downhole chemical technology provider Flotek Industries acquired water-based, drilling fluid-additive technology from ARC Drilling Fluids.

-

Before many of the new chemical and nanoparticle technologies for wellbore strengthening arrived to the marketplace, casing while drilling (CWD) was used for more than a decade to mechanically achieve the same end.