Digital oilfield

EZOps will integrate its Mobile Oilfield Management platform into the college’s energy technology program, giving students hands-on experience with digital tools used in modern oilfield operations.

Digital transformation in the oil and gas industry is likened to a major home renovation—requiring a clear vision, skilled collaboration, patience, and investment in lasting solutions. Though the process is challenging, the end goal is an improved, future-ready operation.

Join TWA Editorial Board member Md Imtiaz as he interviews ONGC’s Western Offshore Asset Executive Director Ravi Shankar.

-

The term digital oil field has become a buzzword in the oil and gas industry these days, with the mention of it bringing up pictures of computers, flashy screens, and programming to mind. In reality, the concept goes beyond these.

-

Two new centers in Bergen, Norway will lean on emerging digital technology to oversee much of the Norwegian operator’s offshore operations.

-

Acquiring data from an abandoned subsea well has been done before, but never quite like this.

-

Wearable computers are turning heads in the oil and gas industry and appear to be on a trajectory for widespread adoption.

-

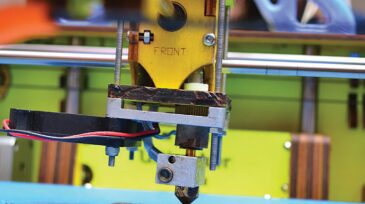

Researchers at Heriot-Watt University in Edinburgh, Scotland, are building replica core samples using 3D printers and installing sensors inside them as they go. Their goal is to directly monitor pore-scale flow behavior from the inside of these so-called “smart rocks.”

-

Case studies from around the world prove that big rewards await companies that optimize the artificial lift systems keeping their mature fields alive. The success stories involve a mix of monitoring, automation, and performance tracking.

-

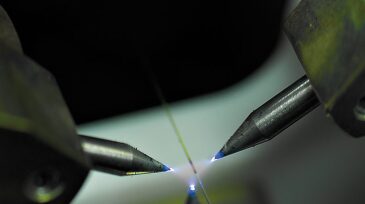

It has been an impressive comeback for a technology that once stood on the brink of failure. The upstream oil and gas industry has largely resolved crippling technical challenges that shortened the life of fiber-optic cables in downhole applications and is now working on a big encore.

-

Industry has developed smart completions, smart wells, and smart fields. The next frontier is real-time reservoir management (RTRM) using all of the data from smart installations, as well as artificial intelligence.