Technology

Over the past decade, oilfield service companies have transformed logging-while-drilling (LWD) development into a faster, collaborative, system-level process that delivers improved reliability from the first run and makes development philosophy as important as the technology itself.

Saipem's center includes a full-scale simulator designed to replicate real operational scenarios to deliver an immersive training experience.

EZOps will integrate its Mobile Oilfield Management platform into the college’s energy technology program, giving students hands-on experience with digital tools used in modern oilfield operations.

-

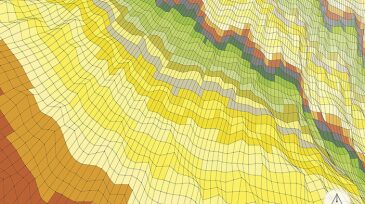

This article briefly reviews two examples of how the integration of data-driven and physics-based models can optimize the history-matching process in reservoir simulation and rate of penetration in drilling operations, leading to more robust and efficient outcomes.

-

While NASA is working aggressively to meet its near-term goal of landing the first woman and next man on the Moon by 2024, its Artemis program also is focused on taking steps that will establish a safe and sustainable lunar exploration architecture. NASA is taking a critical step forward by releasing a solicitation for commercial companies to provide proposals for the…

-

The common energy transition story that we’ve been told is that eventually renewable energy sources will replace oil and gas completely. What’s the problem with oil and gas? CO2 emissions. CCUS allows us to turn this problem into an opportunity.

-

Unconventional producers around the world have been hamstrung by expensive and cumbersome options when it comes to obtaining reservoir data. Among the latest ways to break past these barriers is a new method developed by Canadian researchers and field tested in Australia’s unconventional frontier.

-

Brazil’s national oil company details the results of 6 years of real-time drilling monitoring. The next step is to move toward optimization, then automation.

-

It is a myth that blowouts only occur in high-pressure wells. Being able to investigate the blowout and kill potential on every well as part of the well construction process is an opportunity to increase safety awareness among drilling engineers.

-

What will competitiveness look like in our industry in 10 or 20 years from now? What novel pathways might we envision to restore the natural environment, while creating shareholder value and enhance our license to operate? How can you serve as a potent catalyst for positive change?

-

The oil industry has not treated reservoir crude oil with the same degree of rigor as it does reservoir rock formations. Reservoir fluid geodynamics is a new technical discipline that accounts for hydrocarbon compositional redistribution and phase change in reservoirs in geologic time.

-

Most petroleum engineers understand that engineering calculations involve the properties of fluids. “Fluid” is a term used to describe gases and liquids. An equation of state is nothing more than a fluid model.

-

An overview of two novel applications of the capacitance model, including its implementation during the primary production period and in gas reservoirs.