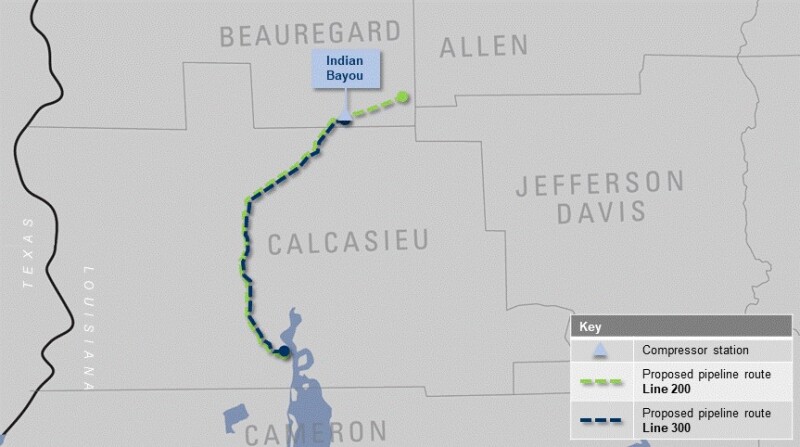

Tellurian has awarded Baker Hughes to provide electric-powered integrated compressor line (ICL) technology and turbomachinery equipment for Driftwood Lines 200 and 300, a natural gas transmission project proposed to be in Beauregard and Calcasieu parishes in southwest Louisiana.

The contract marks the first time Baker Hughes will install its ICL decarbonization technology for pipeline compression in North America. The project will initially include four 19-MW ICL compressors and other turbomachinery equipment for a total of four compressor trains, as well as a LM6000PF+ gas turbine for backup power for the initial phase of the pipeline project at Driftwood’s Indian Bayou Compressor Station.

“We anticipate the project will supply upwards of five and one-half billion cubic feet of natural gas daily, with virtually no emissions,” said Joey Mahmoud, president of Tellurian Pipelines. “Tellurian is doing its part by making this initial $240-million pipeline investment as part of the broader Driftwood Pipeline system which will provide enhanced supply reliability to meet the area’s projected industrial growth in a cleaner, more sustainable manner.”

Baker Hughes’ ICL zero-emissions integrated compressor offers a 40 to 60% smaller footprint, 50% less weight, and improved operational flexibility and availability compared to conventional electric-motor-driven trains. The compressor can go from standstill to full speed and power in 5 minutes, according to Baker Hughes.

While this project marks the technology’s first US application, more than 50 units have been deployed, primarily in Europe, across a variety of applications including pipeline and offshore.

The compressors are built with hermetically sealed casing ensuring no emissions and require minimal downtime due to magnetic bearings for oil-free operations and minimized maintenance, according to Baker Hughes.

The $1.3-billion Driftwood Line 200 and Line 300 is a 37-mile-long dual 42-in.-diameter interstate natural gas pipeline project. The pipelines will provide shippers of Haynesville-sourced gas direct access via new regional infrastructure located near Texas Eastern and Transco Pipeline mainline compressor stations.

The interconnectivity will provide supply reliability to meet the current and projected growth of the industrial, petrochemical, manufacturing, and LNG plants located in or around Lake Charles, Louisiana. The pipelines will be developed and executed in two phases: Phase One is Line 200 and Phase Two is Line 300.

The pipeline system will be able to move up to 3.1 Bcf/D of natural gas as part of the initial operational period, 4.4 Bcf/D as part of the operational period 2, ramping up to 5.4 Bcf/D as part of the third operational period.

Binding open season for Line 200 and Line 300 closed in early 2022.

A draft environmental impact statement from the Federal Energy Regulatory Commission was issued in May and found the impacts from the project would not be significant based on implementation of Driftwood’s planned mitigation measures.

The project is expected to begin construction this year and be in service during 2023.