Today’s drilling engineering teams are continually looking for better ways to mitigate risk and improve health, safety, and environmental conditions at the rig site. Many operators would prefer to acquire a comprehensive suite of petrophysical measurements while drilling—without incurring the risk and cost associated with deployment of chemical nuclear sources.

Traditionally, both wireline and logging-while-drilling (LWD) tools have depended primarily on radioisotopes such as americium-beryllium to generate high-energy neutrons for porosity measurements, and cesium to generate gamma rays for bulk density measurements. However, transportation, storage, handling on the rig floor, and potential abandonment of radioactive sources at the wellsite should the tools become stuck require special safety precautions and costly, time-consuming procedures. In remote geographic regions, mobilizing chemical sources can be slow and logistically complex.

If a bottomhole assembly (BHA) with a chemical source becomes stuck, complicated fishing procedures can waste precious rig time, and delay eventual production of oil and gas.

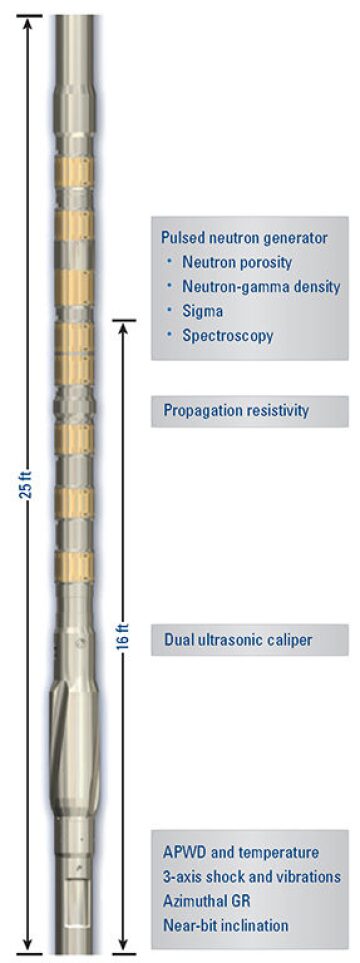

To meet the growing industry need for an alternative to radioactive chemical sources, Schlumberger recently released NeoScope sourceless formation evaluation-while-drilling solution (Fig. 1). This technology is unique in three ways:

- It is the first LWD tool to introduce a completely new nuclear measurement to the industry—sourceless neutron gamma density (SNGD).

- It is the only tool in the industry that provides formation density and neutron measurements without the need for chemical nuclear sources.

- Finally, it is the first tool to provide collocated density and neutron measurements (Fig. 2).

Development and Field Testing

LWD tools have typically used two chemical nuclear sources to obtain neutron porosity and bulk density. In partnership with Japan Oil, Gas, and Metals National Corporation, Schlumberger first developed and deployed a pulsed neutron generator (PNG) for commercial standard neutron porosity, spectroscopy, and sigma measurements 7 years ago, eliminating the need for one of the chemical sources (241AmBe). However, development of SNGD was not yet mature enough for commercial use. The only way to acquire a reliable density measurement was still to use a cesium source. Hence, it remained impossible for operators to obtain a comprehensive sourceless suite of petrophysical data while drilling.

Ongoing research and engineering led to modifications of existing technology, design of new detectors, and development of sophisticated characterization algorithms and calibrations to provide the first commercial SNGD measurement—a true breakthrough.

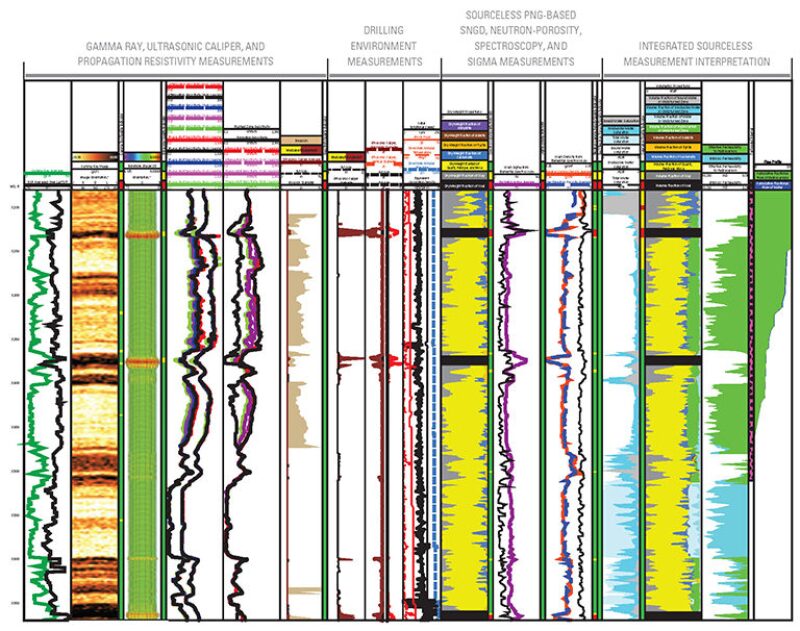

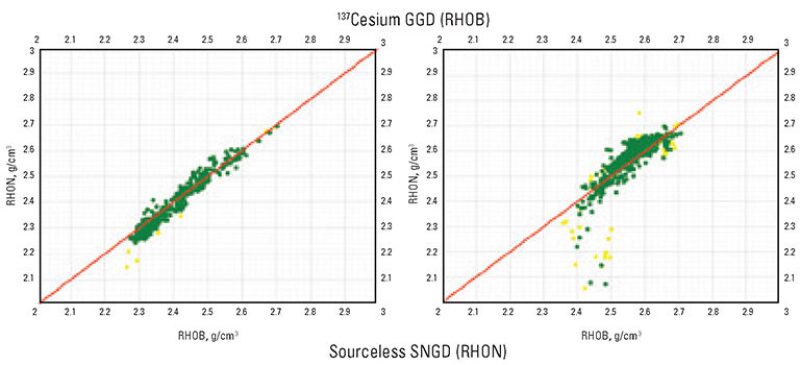

Since 2005, extensive laboratory modeling and experimentation, as well as more than 200 field tests in more than 30 countries have been conducted to verify and refine the new SNGD measurement. Tests have been carried out in a wide range of formations under many different environmental conditions. Comparisons of the new PNG-based density measurement with conventional bulk densities derived from chemical sources showed good correlations both in carbonates and sandstone formations, onshore and offshore (Fig. 3). Field testing extended through early 2012, and the commercial solution was officially released in June.

PNG. Unlike radioisotopes, which are “always on,” emitting a continuous stream of neutrons, PNGs produce neutrons “on demand.” They generate high-energy neutrons in carefully timed pulses only when the tool receives electrical power from the turbine in the measurement-while-drilling (MWD) system. When mud flow stops, the MWD turbine powers down and the PNG turns off.

In addition, a series of built-in safety control mechanisms prevent any possibility of accidentally activating the PNG either at surface or downhole. As such, it can be transported, stored, handled and, if necessary, abandoned without any specific safety requirements or costly procedures. There are no restrictions on wellsite storage or manipulation of PNG-based tools, and government agencies, such as the US Nuclear Regulatory Commission, have exempted them from special precautions for abandonment in oilfield wells.

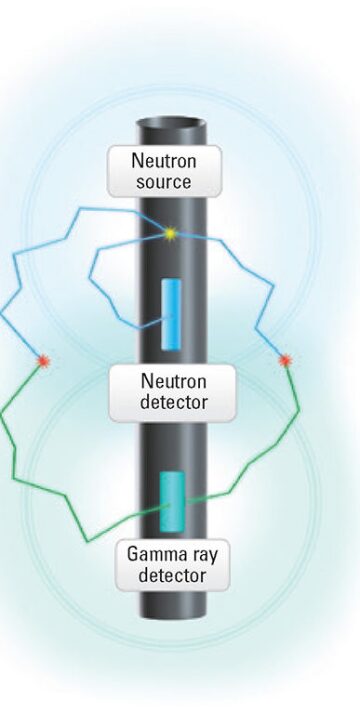

The new SNGD measurement. Fast neutrons emitted by the PNG collide with formation nuclei, creating a secondary source of gamma rays, which are received by a special set of detectors in the tool (Fig. 4). Induced gamma rays arriving at long-spaced detectors exhibit significant sensitivity to formation density.

Since SNGD is a complex measurement, sophisticated algorithms and environmental corrections are required. While conventional density measurement is accurate to 0.015 g/cm3 in clean sandstones and carbonate formations, the SNGD measurement has an accuracy of 0.025 g/cm3 under the same conditions. SNGD is less dependent on good contact with the formation than conventional density.

Applications and Case Studies

NeoScope sourceless technology is ideal for any drilling or logging situation in which the operator is concerned about the risks or logistic complications associated with the use of chemical nuclear sources. NeoScope service reduces these operational risks while allowing existing field formation evaluation models to be applied. These models are generally based on density and neutron measurements and many have been refined over numerous years.

Exploration wells. Exploratory wells and new frontiers pose greater risks and unknowns. Obtaining real-time formation-evaluation data earlier allows drillers and geoscientists to avoid running blind. Early formation assessment with LWD can optimize the drilling program and logging program, and help an operator decide when to plug and sidetrack. Sourceless formation-evaluation technology completely eliminates the risk of losing a chemical source and having to undertake complex abandonment procedures.

Unconventional plays. In unconventional plays, long horizontal wellbores increase the potential for stuck pipe. Sourceless LWD data not only evaluates reservoir quality in real time for better well placement, but also provides critical input to rock mechanics necessary to optimize multistage hydraulic fracture completion design.

Development wells. In development drilling, any operational or logistical delay can result in additional expense and postpone production. In the case of a stuck pipe or a lost-in-hole incident, costly fishing can be avoided. The BHA can be abandoned and sidetrack operations commenced without further delay.

Case study 1: Offshore, tight carbonates. An operator drilling an offshore exploration well wanted to acquire a full suite of petrophysical measurements and properly characterize the reservoir while avoiding the potential risk and cost of having to abandon chemical sources. The operator decided to run the new sourceless service, saving the cost of subsequent logs that would have required chemical sources—in this case, saving approximately USD 500,000. The neutron-gamma density measurement in conjunction with other real-time data provided an accurate saturation profile, estimated matrix properties, and helped identify high-potential hydrocarbon zones.

Case study 2: Onshore, sandstone reservoir. While logging a deviated well in the Western Desert of Egypt, the operator encountered a zone with significant wellbore stability issues. The company decided the best approach would be to deploy sourceless LWD tools to complete the evaluation, and rapidly mobilized the service to the wellsite. The PNG-based technology provided high-quality data over the full 1,774-ft interval, including the oil-bearing reservoir. The LWD measurements compared favorably with those obtained from wireline conventional logs. Eliminating the time and expense of shipping chemical LWD sources to the wellsite saved 7 days and USD 200,000.