In the offshore oil and gas industry, where every decision affects cost and efficiency, the management of wells is a complex challenge. Operators often face a balancing act between optimization of reservoirs and minimization of operational downtime. Intelligent completions show promise of best-in-class precision and control, but their story is one of both opportunity and unrealized potential.

Since the first deployment in the North Sea in 1997, intelligent completions have reshaped reservoir management with real-time monitoring and zonal control tools. These systems enable operators to manage production and injection across multiple zones to extend well life and increase recovery. Yet, despite their transformative potential, the adoption of intelligent completions has been relatively limited due to perceived complexity and inefficiency.

The Barriers Holding Back Adoption

Traditional hydraulic systems, while groundbreaking in their time, required a series of incremental steps to achieve the desired choke position. Valve adjustments often required production shut-in, which created delays and required justification from asset owners. This process not only interrupted operations but also diminished the appeal of optimization.

In subsea environments, the operational complexities increased. Adjusting valves involved pressurizing and venting cycles, which could take hours for a single valve manipulation. When multiple valves were installed in a single string, the cumulative time required became a significant barrier, which discouraged operators from fine-tuning well performance.

These issues prevented operators from leveraging the full capabilities of intelligent completions. Many wells continued to operate suboptimally and left valuable resources untapped.

A Turning Point for Intelligent Completions

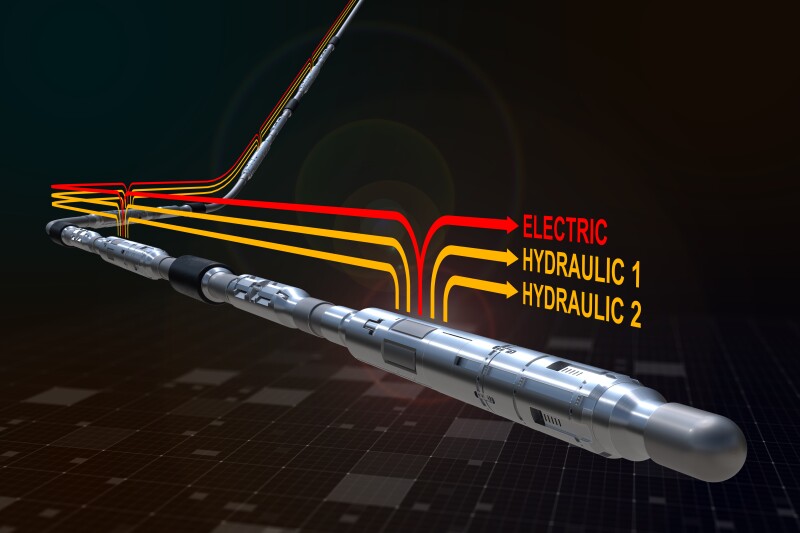

The industry reached a pivotal moment with the development of Halliburton's Turing® electro-hydraulic control system, the next generation of SmartWell® intelligent completions technology. These advancements address the longstanding challenges and offer simpler operations and faster response times without the need to shut in production (Fig.1).

These bi-directional interval control valve (ICV) systems represent a significant shift, as they allow operators to move valves directly to specific positions and bypass the incremental adjustments required by traditional systems. This ability saves time and ensures that reservoirs are managed with far greater precision.

In a subsea setting, these advancements redefine what is possible. Operators no longer need to endure the drawn-out cycles of older systems. Instead, valves adjust quickly even when multiple zones are involved to enable more responsive and efficient reservoir management.

Stories of Success: Intelligent Completions in Action

Recent projects illustrate the impact of these technologies. In the Middle East, Halliburton deployed a twelve-zone SmartWell® technology and demonstrated how precise control over individual zones can transform well performance. Operators adjusted for water breakthrough and maintained production in other areas, which improved recovery and adapted to reservoir conditions (Fig. 2).

In Latin America, operators implemented the Fuzion® downhole wet-mate connector for deepwater completions. When they installed the SmartWell® technology separately from the upper completion, operators reduced fluid losses and installation times. The disconnect feature also enabled quick and safe recovery of the upper completion without disruption of the lower completion system—a critical advantage in dynamic production environments.

These examples highlight how Halliburton's innovative systems help operators overcome logistical and operational hurdles to unlock additional value.

The Power of Integrated Data

Technology alone isn't enough to optimize reservoir performance. The integration of advanced analytics and automation is what truly unlocks the potential of intelligent completions (Fig. 3).

Halliburton's digital platforms, such as Clariti® digital reservoir management suite and Visum® fiber optics and data analytics services, pair ICVs with surface software that analyzes reservoir data in real time. This allows operators to identify problematic zones and take corrective action without delays. Automation adds another layer of efficiency. Workflows can adjust valves dynamically in response to changing reservoir conditions.

Consider a well with high water influx. In the past, this issue required the shutdown of production and adjustment of valves to resume operations. With these systems, sensors detect the problem, and automated workflows can adjust the valve in an instant to maintain production and resolve the issue. These capabilities enhance recovery and minimize production losses.

Designing for Compatibility

One of the most important aspects of Halliburton's next-generation systems is their ability to adapt to the infrastructure. Operators can deploy these technologies without extensive modifications to subsea equipment to facilitate a smooth transition.

Electro-hydraulic systems, for instance, work with standard subsea feedthroughs and production trees. This compatibility reduces deployment complexity and allows operators to adopt advanced systems across both new and existing wells.

A New Era of Reservoir Management

The story of intelligent completions is evolving. What began as a concept limited by practical challenges became a cornerstone of modern reservoir management. With advancements in technology, automation, and data integration, operators can now achieve levels of precision and efficiency that were once out of reach.

As the industry continues to adapt, the role of intelligent completions will grow. Multizone systems are becoming more common to provide operators with the tools to manage increasingly complex reservoirs. Projects such as the twelve-zone deployment in the Middle East show what is possible when technology and strategy align.

For operators, the lesson is clear: the future of reservoir optimization depends on embracing the full capabilities of intelligent completions. With systems like Halliburton's Turing® electro-hydraulic control system, the next generation of SmartWell® intelligent completions technology as pioneers, the industry can move beyond the limitations of the past. These technologies transform the management of wells and development of resources with efficiency and in a sustainable manner.