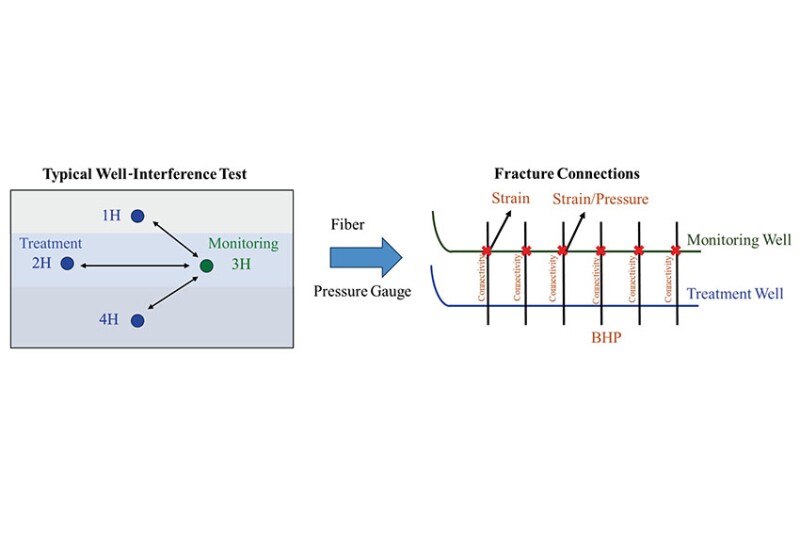

Identifying the contribution of each fracture from each cluster in a multifractured horizontal well can be challenging; however, understanding fracture connections at the cluster level can provide detailed guidance for optimizing completion designs and well spacing. This work proposes a new method to interpret far-field strain change and pressure data to quantify fracture connectivity and properties at the cluster level.

Introduction

In this study, the authors first analyzed strain and pressure responses during a well interference test in the US Department of Energy’s Hydraulic Fracturing Test Site (HFTS)-1 (Phase III). Based on the assumption of a 1D linear flow equation, a new model was developed to describe early-time pressure changes in the fracture during production. By incorporating the linear relationship between pressure, stress, and strain, the model was extended to capture strain variations along the fracture. The model was then applied to interpret pressure gauge data and corresponding strain measurements, validating its accuracy.