The objective of the complete paper is to apply a developed workflow to determine the propped hydraulic fracture geometry in a horizontal multistage fractured well, incorporating production, pressure, and strain data. The essential feature of the workflow is the integration of offset monitoring well data. The model is validated with data from the US Department of Energy (DOE) Hydraulic Fracture Test Site-I, Phase III (HFTS-I, Phase-III), in the Eagle Ford shale.

Introduction

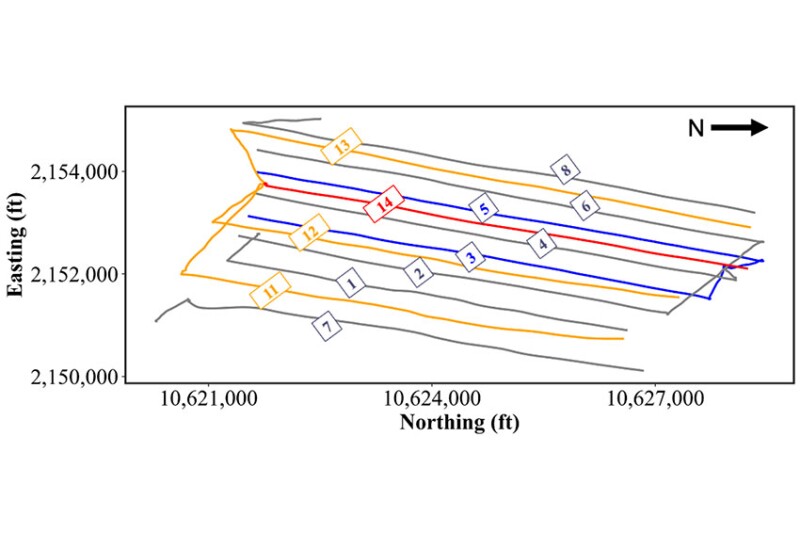

The objective of Phase III is to improve the recovery of the Zgabay-A field through liner refracturing of two producing wells (3H and 5H) and drilling of three infill wells (11H, 12H, and 13H). The test site included drilling of a monitoring well, 14H, that acquired extensive diagnostic data sets during preload, refracturing, infill-well stimulation, and production interference. Because of limited surface spacing, the infill wells and monitoring well were drilled from south to north, opposite to the direction of the parent wells.

Pressure depletion and in-situ stress changes found near the parent-well fracture network system will result in newly stimulated hydraulic fractures of refrac and infill wells preferentially propagating toward these areas of lower pressure, causing fracture hits.