For decades, the industry has progressively digitized to capture efficiencies, and today that investment is paying dividends. An approach that began as a “good idea” has transformed operations, improved processes, and is enabling automation at a level never before experienced in the oil and gas sector. The potential for achieving even more widespread automation is enormous, and today’s successes are paving the way forward.

Applying Advanced Technology

In the current well-construction landscape, digitalization is ensuring repeatability of operations by consistently meeting goals, driving efficiencies through shorter, more precise operations, minimizing well construction time and costs, enhancing production via optimally placed, quality, fit-for-purpose wellbores, and improving health, safety, and environmental performance.

These goals have been achieved progressively, first by leveraging best-in-class processes, next by digitizing them, and finally, by automating them.

Drilling operations were among the first to leverage data to implement automated activities and continue to lead with proven tools and sound methodology. Results from applying the capabilities of the i-Trak automated advisory and i-Trak automated directional drilling (ADD) services show that this technology improves drilling accuracy.

The solutions take on repetitive tasks so drillers can focus on optimizing drilling parameters during execution. Specifically, in automated directional drilling, the predictive controller leverages artificial intelligence to monitor and adjust the well trajectory in real time. This process unburdens the directional driller, allowing for that freed-up capacity to be refocused on supervising more value-added advisory systems including borehole pressure, tripping speeds, torque-and-drag trends, hole cleaning, and rate of penetration (ROP). The result is consistent, predictable drilling performance from well to well, with minimal variance or risk of human error.

Real-time data analytics is an essential component of this solution. Working alongside the automated advisory and ADD systems, Corva, a cloud-based developer of apps for optimizing drilling and completions operations, applies advanced analytics to simplify the process of capturing mission-critical data and converting it to actionable information. The approach eliminates manual tracking and the associated inconsistencies that make it difficult to understand crew performance.

More importantly, real-time analytics enable immediate anomaly detection and the identification of where improvements in tripping speeds, connection times, bottomhole-assembly changeouts, and casing runs can be achieved.

Integrating Automation, Leveraging Analytics

Introducing new technology requires thoughtful change management, particularly where automation is concerned, because in many cases workers who are instrumental in implementing automated solutions consider the technology itself to be a threat. Therefore, helping new users grasp how the technology works is critical to getting the best value from it. And fundamental to achieving that goal is ensuring that users understand how the automated solution is meant to support them, so they do not resist adoption because of suspicions that the technology is intended to replace them.

Transparency is a vital part of change management. In introducing automated drilling technology, Baker Hughes recognized the importance of providing a real-time dashboard that allowed drillers to visualize what was happening downhole and to take immediate action if required. When the operator, drilling contractor, crew, and remotely located engineering team are looking at the same data, they can interact and collectively determine how to proceed based on real-time observations of how the technology is impacting operations.

The effort revealed how critical open communication is. By keeping communication pathways open and encouraging feedback, it is possible to move progressively to achieve full automation.

Often, the first step in implementing ADD services is to use the technology in “advisory mode” in which the system creates parameters recommendations based on real-time data and proprietary algorithms which are visible to the crew for evaluation but not yet enacted automatically.

As the crew gains confidence in the technology’s ability to provide optimal steering commands or parameter recommendations, they become more inclined to follow the guidance provided by the system. And as they become familiar with it, more of the drilling process can move from advisory mode to “active mode,” which involves a closed-loop well-control system that delivers full automation.

Corva was instrumental in helping stakeholders understand performance. Integrating real-time software and data from offset wells to provide advanced analytics enabled benchmarking against predefined key performance indicators. The developer’s platform provides apps that offer a view of real-time operations, visualizing hydraulics and essential rig metrics as well as days vs. depth, allowing decisions to be made to improve performance.

Following a staged approach gives drillers time to become accustomed to using the technology and to trust the analytics. This was the approach employed for TotalEnergies on the Fénix development offshore Argentina.

Implementing the Solution

The Fénix development is located approximately 60 km offshore Tierra del Fuego. The field, which is part of the Cuenca Marina Austral 1 license block, is arguably the most important offshore gas complex in Argentina. This concession currently supplies 17 million m3/D of gas to the local market, and Fénix will increase production capacity by approximately 10 million m3/D, representing 8% of Argentina’s gas production.

Because of the complexity of the wellbore geometry and geological conditions, the operator expected to encounter hole-cleaning challenges, issues with torque and drag above drillstring limits, and potential stuck-pipe risks. These were identified among the main hazards during the project planning phase.

At the outset, TotalEnergies and Baker Hughes worked together to design the Fénix project’s extended-reach-drilling (ERD) wells. A pre-established communication protocol supported data-driven decision making to implement preventive measures that avoided nonproductive time, resulting in a more efficient well-construction process.

In conventional well-construction operations, a one-time simulation is performed based on initial parameters during planning. But for the Fénix well project, a key pillar of the advisory services was a digital twin—an amalgamation of transient physics-based and data-driven models deployed in real time to continually consume sensor data and historical simulation results, producing evergreen modeled outputs that could be compared with reality. This enabled dynamic reaction to unplanned events such as the unexpected buildup of cuttings beds or unexpected high downhole dysfunction in the drillstring.

The digital twin worked in conjunction with the automated advisory and ADD systems to improve drilling performance.

The digital platform, coupled with innovative product solutions and 24/7 monitoring from a remote operations center, streamlined drilling and enabled early detection of issues downhole and real-time adjustments to keep the well in the best area of the zone for the duration of the ERD program.

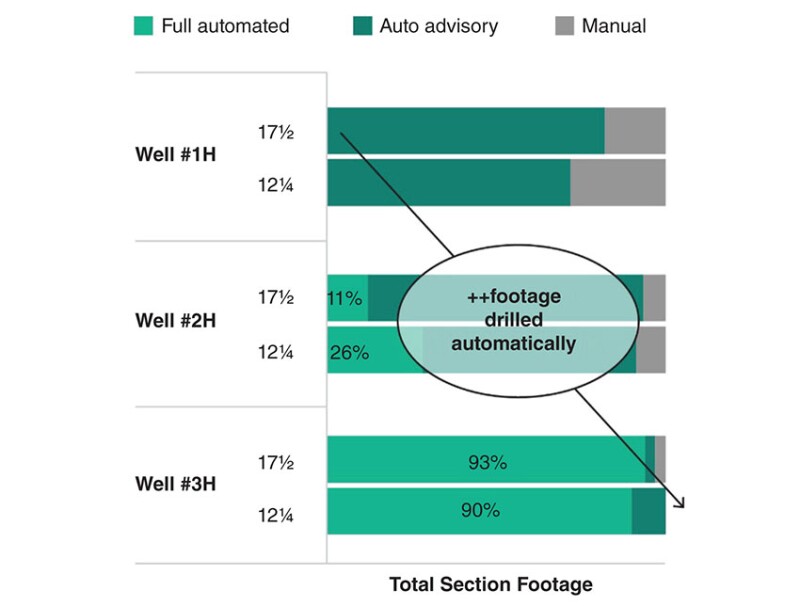

Well construction on the Fénix project comprised three development wells drilled in a batch-style campaign. Staged implementation of both i-Trak and Corva was planned from the 17.5‑in. section down on each of the three gas wells.

Well #1H. Initially, TotalEnergies intended to drill the first 843 m of the 17.5-in. segment and 732 m of the 12.25-in. section of the #1H well in shadow mode. Instead, 82% of the 17.5-in. section and 54% of the 12.25-in. section were drilled in advisory mode. Once the crew became familiar with drilling in advisory mode and was more confident in the ADD system’s ability to prescribe and execute optimal well placement, the decision was made to take the next step with the technology faster than expected.

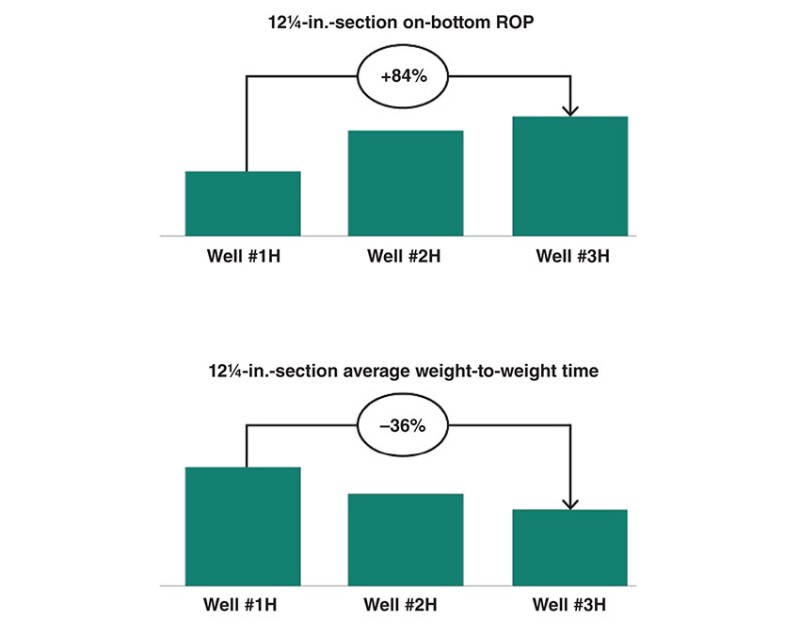

Well #2H. The initial segments of both the 17.5‑in. and 12.25-in. sections of the #2H well were drilled in advisory mode. Then, the team moved to closed-loop drilling for the final sections—a total of 1041 m in the 17.5-in. section and 1289 m in the 12.25‑in. section. In the 12.25-in. section, automated advisory recommendations proposed reducing reaming time prior to making connections because real-time models consistently showed the hole was being cleaned during drilling. This reduced weight-to-weight times by 7 minutes relative to the previous 12.25-in. section. This resulted in a record-setting time for the section that improved upon the next-best drilling time by more than 3 hours.

Well #3H. Based on the results of the first two wells, TotalEnergies elected to use advisory mode for only the first small segment of the 17.5-in. section of the #3H well, employing automation for the remaining 94% of the wellbore.

The team utilized advisory and ADD services, including hole-cleaning monitoring along with vertical section and ROP data-driven optimization in the #3H well’s 17.5-in. section. This resulted in 331 m more footage being drilled in the #3H in the same amount of time as was spent drilling the #1H well, and instantaneous ROP increased by 52%.

About 30% of the footage was drilled automatically using ADD and employing Corva apps to visualize and analyze performance improvements. The 17.5-in. section of the #3H well was the most successful, increasing on-bottom ROP by 41% and reducing weight-to-weight time by 25%, with 92% of the section drilled automatically using ADD.

Employing advanced technologies across these wells delivered significant savings. The drilling successes achieved on the Fénix project prove the industry is well past the point of merely talking about automation and is moving well down the road toward broad implementation.

Setting Standards for Automated Performance

The Fénix project is a milestone for Argentina, marking the first time the Baker Hughes-developed automated advisory and ADD services and Corva technologies were deployed together offshore. The faster and more accurate decision-making enabled by the advanced technology led to increased ROP and reduced weight-to-weight times in three ERD wells, proving the value of automated drilling and establishing a benchmark for future projects in similar drilling environments. The exceptional results achieved through automation and advanced real-time data analytics set a new bar for drilling performance.

Mariano Pozo, SPE, is the global head of drilling engineering specialties for TotalEnergies, based in Pau, France. With over 2 decades of experience across Latin America, southeast Asia, and Europe, Pozo has led multidisciplinary teams in delivering complex well designs for onshore, offshore, deepwater, unconventional, and carbon capture and sequestration projects. He is the corporate focal point for drilling automation and the technical referent for procurement, driving the global implementation of cutting-edge technologies across TotalEnergies’ affiliates. His career spans leadership roles in Argentina, Myanmar, and France, and includes deep expertise in well construction and cost-efficient drilling operations. Pozo’s international perspective and technical depth make him a key figure in advancing digital and engineering excellence in the energy sector.

Matthew Forshaw, SPE, leads Baker Hughes’ global well-construction automation business. With over a decade of international experience, he began his career offshore in the North Sea before progressing through roles in operations management, technology development, commercial strategy, and product leadership. Forshaw led the team that delivered the world’s first autonomous reservoir section and has contributed extensively to the industry by authoring more than 20 SPE papers and holds multiple patents for digital well construction and drilling-automation innovations.